Hexagonal boron nitride epoxy compound anticorrosion coating and preparation method and application thereof

A technology of hexagonal boron nitride and anti-corrosion coatings, applied in the field of coatings, can solve the problems of poor coating protection effect and easy agglomeration, and achieve the effect of not easy to sink, low cost, and long-lasting anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The embodiment of the present invention also provides a preparation method of hexagonal boron nitride epoxy composite anticorrosion coating, comprising:

[0051] Uniformly disperse hexagonal boron nitride and polyaniline nanofibers in a solvent to obtain a hexagonal boron nitride dispersion, and then mix the hexagonal boron nitride dispersion with epoxy resin, additives and solvents to form a component one;

[0052] And, the epoxy resin curing agent is provided as the second component, or the epoxy resin curing agent is diluted with a solvent to form the second component.

[0053] In some more specific embodiments, the preparation method may include the following steps:

[0054] Weighing a certain amount of hexagonal boron nitride and polyaniline nanofibers and dispersing them in a solvent, stirring or ultrasonically obtaining a hexagonal boron nitride dispersion;

[0055] Add the hexagonal boron nitride dispersion into epoxy resin, additives and solvents, and stir for ...

Embodiment 1

[0075] (1) 0.047g polybutylaniline nanofibers (morphology such as figure 1 shown, and can be prepared by referring to the method described above), 0.18g hexagonal boron nitride nanosheets (thickness about 3 ~ 5nm) dispersed in 40mL tetrahydrofuran, ultrasonic 1 hour to mix uniformly to obtain hexagonal boron nitride dispersion, and then The hexagonal boron nitride dispersion is added to 30g epoxy resin (model is E44, purchased from Jiangsu Wujiang Heli Resin Factory), 2g leveling agent, 2g anti-settling agent, 3g defoamer and 8g xylene reagent, Mechanical stirring was used for 30 minutes to mix the various substances uniformly to obtain component 1.

[0076] (2) Mix 7.5g polyamide 650 and 6g xylene solution evenly to prepare component 2.

[0077] (3) Mix component one and component two directly, use a high-speed mixer, and stir for 30 minutes to obtain an epoxy composite coating containing 0.5 wt% hexagonal boron nitride.

[0078] (4) The obtained hexagonal boron nitride epo...

Embodiment 2

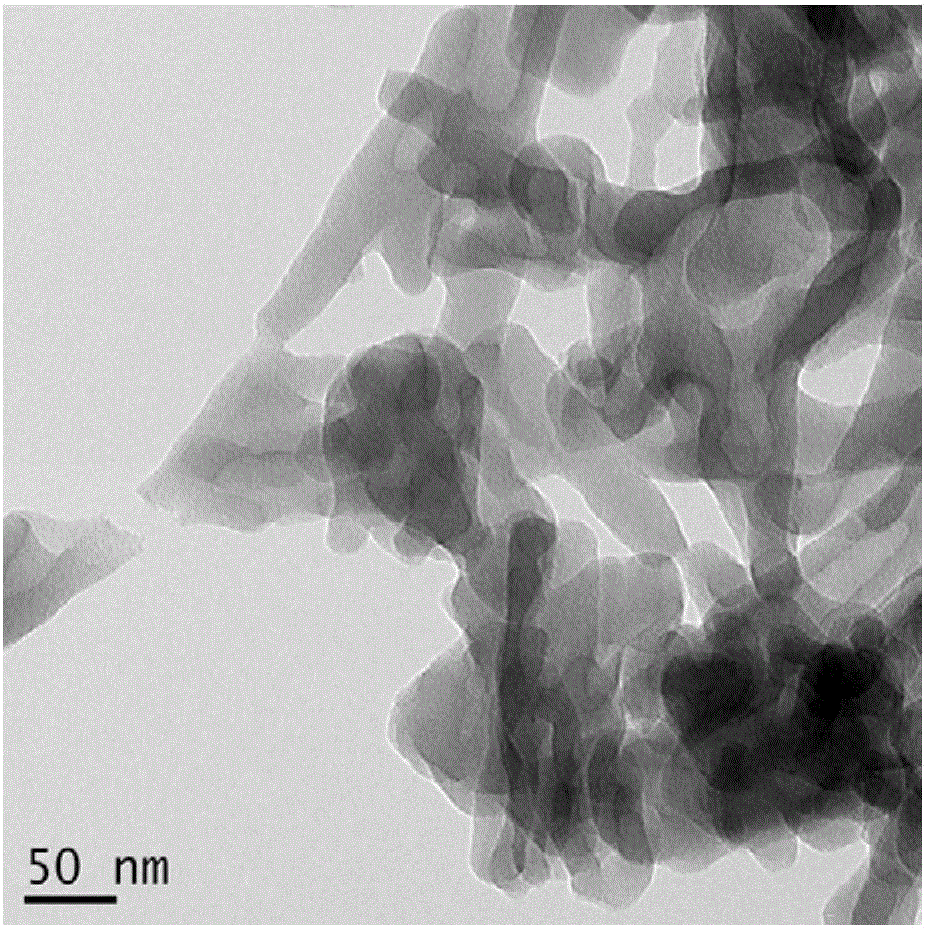

[0080] (1) Disperse 0.095g of poly-o-toluene nanofibers (about 10nm in diameter and about 0.8μm in length) and 0.38g of hexagonal boron nitride nanobelts (about 8-10nm in thickness) in 80mL of tetrahydrofuran and sonicate for 1 hour until they are evenly mixed Obtain the hexagonal boron nitride dispersion, then add the hexagonal boron nitride dispersion to 30g epoxy resin (bisphenol S type epoxy resin, methylol bisphenol F type epoxy resin or hydrogenated bisphenol F type ring Oxygen resin, etc.), 2g leveling agent (polydimethylsilane or polymethylphenylsiloxane, etc.), 2g anti-settling agent (polyamide wax or organic swelling, etc.), 3g polyether defoamer and In 8 g of toluene reagent (model E44, purchased from Jiangsu Wujiang Heli Resin Factory), mechanical stirring was used for 30 minutes to mix the various substances uniformly to obtain component 1.

[0081] (2) Mix 7.5g of polyamide 650 and 6g of toluene solution uniformly to prepare component 2.

[0082] (3) Component 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com