Method and device for preparing vertical orderly carbon nano tube/polyaniline composite membrane

A carbon nanotube, vertically ordered technology, applied in the field of carbon nanotube/polyaniline composite film, can solve the problems of difficult to obtain thin film CNTs/polymer composite film, poor order of CNTs in the composite film, etc., and achieve cost Inexpensive, easy to operate, high order effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

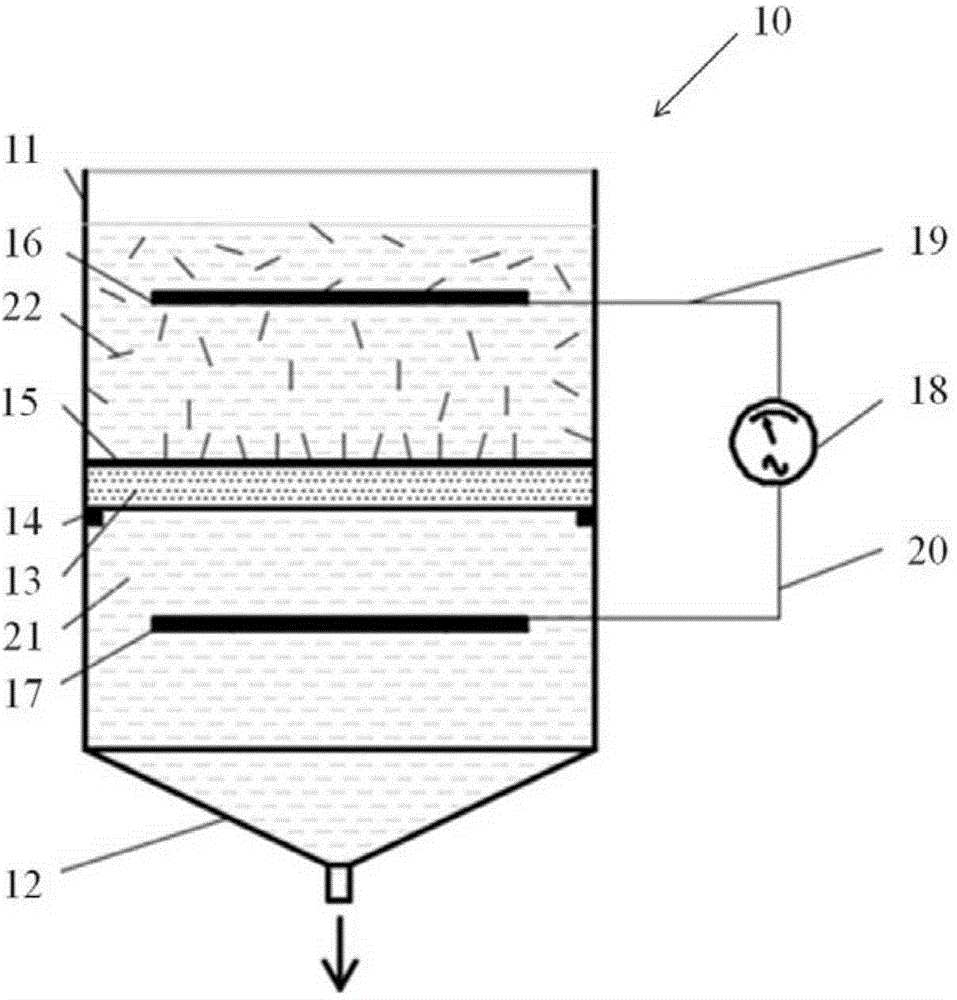

[0025] figure 1 It is a structural schematic diagram of the suction filter-electric field device of the present invention.

[0026] Such as figure 1 As shown, the suction filtration-electric field device 10 provided by the present invention includes a body 11, a funnel 12, a sand core 13, a pad 14, a filter paper 15, an aluminum electrode 16, an aluminum electrode 17, an AC power supply 18, a wire 19, a wire 20, a storage Liquid bottle (not shown in the figure) and vacuum pump (not shown in the figure).

[0027] The body 11 is a hollow structure made of polymethyl methacrylate. The upper end of the main body 11 is provided with an opening, so that the mixed aqueous dispersion 21 of carbon nanotubes and polyaniline enters the main body 11 through the opening.

[0028] The funnel 12 is connected to the lower end of the body 11, communicates with the body 11, and has a downward outlet.

[0029] The sand core 13 is disposed in the middle of the body 11 .

[0030] A spacer 14 ...

Embodiment 2

[0037] The suction filtration-electric field device 10 in is used to prepare carbon nanotube / polyaniline composite membrane, and the preparation method comprises the following steps:

[0038] Step 1, preparing a mixed aqueous dispersion.

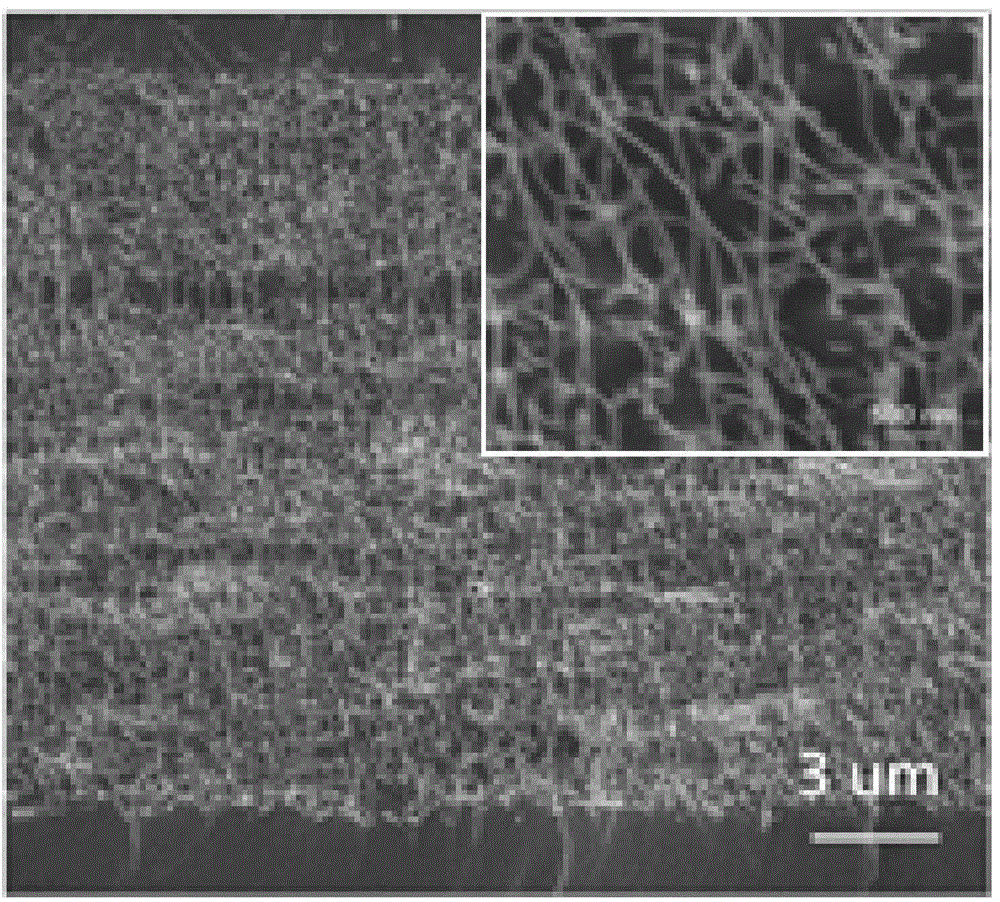

[0039]First, carbon nanotubes (CNTs) are subjected to acidification treatment, and the method of acidification treatment can refer to the literature J. Liu, A.G. Rinzler, H. Dai. Fullerene pipes [J]. Science, 1998, 280, 1253-1256. In this embodiment, the single-walled CNTs after the acidification treatment have a diameter of 1-2 nm and a length of about 1 μm. Then, polyaniline (PANi) nanofibers were prepared by chemical oxidation polymerization. The preparation method is as in the literature H.D.Tran, Y.Wang, J.M.D'Arcy, et al.Toward an understanding of the formation of conducting polymer nanofibers[J].ACS NANO , 2008, 2(9):1841-1848. In this embodiment, the PANi nanofibers prepared by the above method have a diameter of about 40 nm and a...

Embodiment 3

[0049] In this embodiment, the steps of preparing the CNTs / PANi composite membrane are the same as in the second embodiment, but the distance between the aluminum electrode 16 and the aluminum electrode 17 and the filter paper 15 is adjusted to 12 mm.

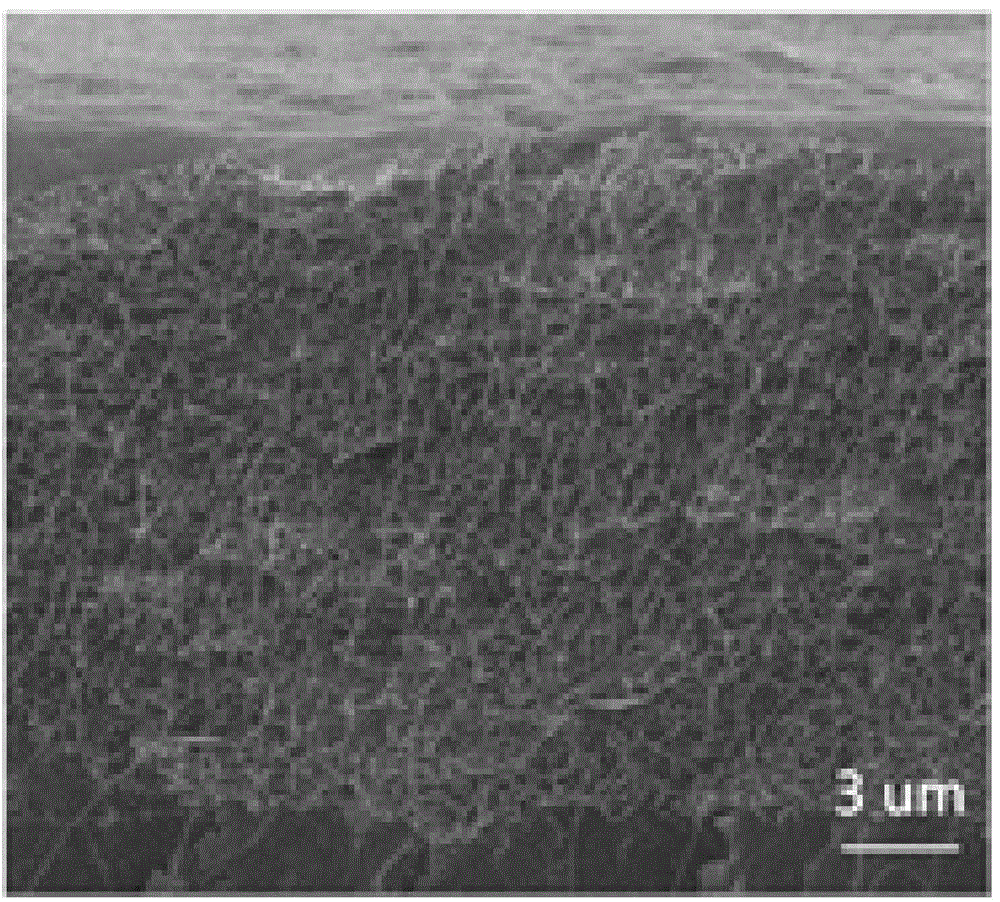

[0050] image 3 It is the cross-sectional SEM image of the CNTs / PANi composite film prepared in embodiment three;

[0051] Such as image 3 As shown, the thickness of the CNTs / PANi composite film prepared in this example is about 20 μm, and the CNTs are evenly dispersed on the surface of the composite film. lowered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com