Polyaniline nano-fiber electrode material for super capacitor and preparation method thereof

A supercapacitor and nanofiber technology, which is applied in the manufacture of hybrid/electric double layer capacitors, capacitors, electrolytic capacitors, etc., to achieve the effects of simple preparation process, inhibition of agglomeration and secondary growth, and controllable size and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

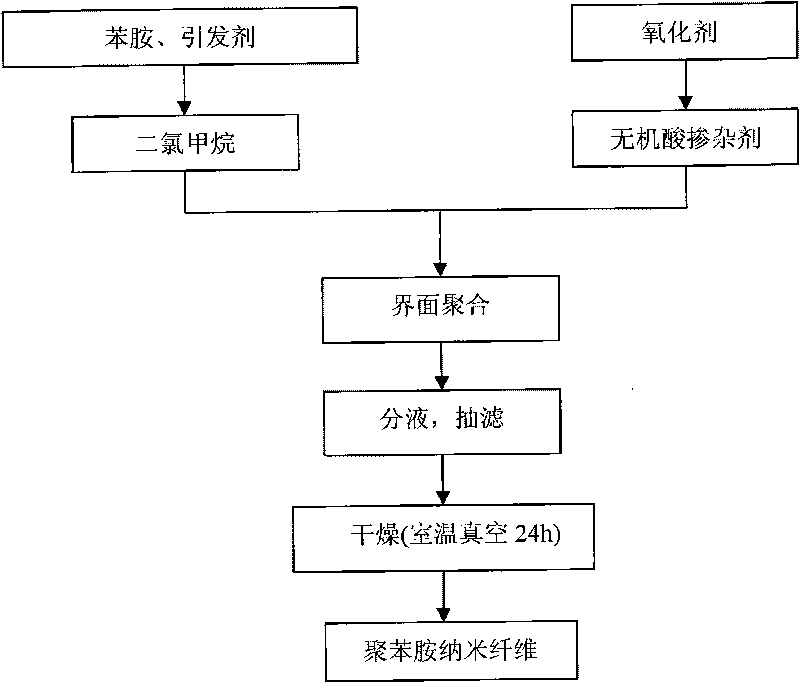

[0024] Embodiment 1: supercapacitor electrode material polyaniline nanofiber I.

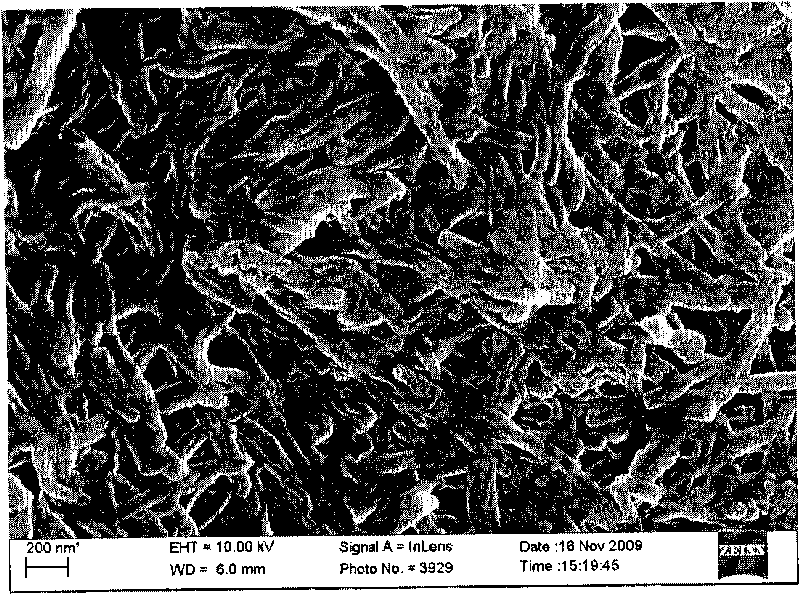

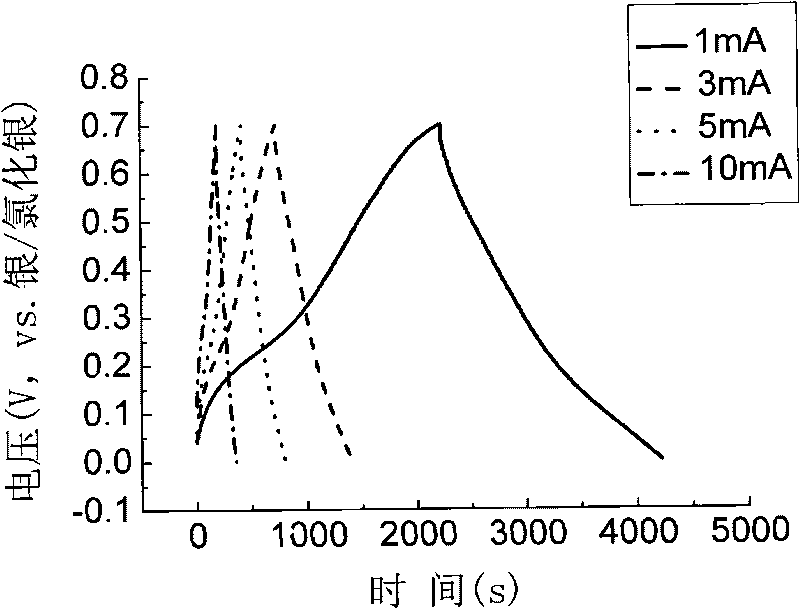

[0025] Dissolve 4mmol of aniline monomer and 10mg of p-phenylenediamine in 80ml of dichloromethane, dissolve 0.23g of ammonium persulfate in 80ml of 1mol / L hydrochloric acid, mix the two solutions, and polymerize at 1°C for 12 hours to synthesize polyaniline nanofibers . Liquid separation, suction filtration, washing with deionized water and ethanol respectively, and vacuum drying at room temperature for 24 hours to obtain polyaniline nanofiber powder. The prepared polyaniline nanofibers were characterized by field emission scanning electron microscopy (such as figure 2 ), indicating that the prepared polyaniline nanofibers have a diameter of about 100 nm and a length of 1 μm. The electrochemical test of the three-electrode system was carried out on the prepared polyaniline nanofibers: the electrolyte was 1mol / L H 2 SO 4 , the reference electrode is Ag / AgCl, and the auxiliary electrode is pl...

Embodiment 2

[0026] Embodiment 2: Supercapacitor electrode material polyaniline nanofiber II.

[0027] Dissolve 8mmol of aniline monomer and 20mg of p-phenylenediamine in 40ml of dichloromethane, dissolve 0.46g of ammonium persulfate in 40ml of 1mol / L hydrochloric acid, mix the two solutions, and polymerize at 1°C for 6 hours to synthesize polyaniline nanofibers . Liquid separation, suction filtration, washing with deionized water and ethanol respectively, and vacuum drying at room temperature for 24 hours to obtain polyaniline nanofiber powder. The electrochemical test of the three-electrode system was carried out on the prepared polyaniline nanofibers: the electrolyte was 1mol / L H 2 SO 4 , the reference electrode is Ag / AgCl, and the auxiliary electrode is platinum electrode. The test shows that: when the discharge current is 1mA, the specific capacitance of polyaniline nanofiber reaches 459Fg -1 , as the current density increases from 1mA to 10mA, the specific capacity decays by 13%....

Embodiment 3

[0028] Embodiment 3: Supercapacitor electrode material polyaniline nanofiber III.

[0029] Dissolve 8mmol of aniline monomer and 20mg of p-phenylenediamine in 40ml of dichloromethane, dissolve 0.46g of ammonium persulfate in 40ml of 1mol / L sulfuric acid, mix the two solutions, and polymerize at 1°C for 12 hours to synthesize polyaniline nanofibers . Liquid separation, suction filtration, washing with deionized water and ethanol respectively, and vacuum drying at room temperature for 24 hours to obtain polyaniline nanofiber powder. The electrochemical test of the three-electrode system was carried out on the prepared polyaniline nanofibers: the electrolyte was 1mol / L H 2 SO 4 , the reference electrode is Ag / AgCl, and the auxiliary electrode is platinum electrode. The test shows that: when the discharge current is 1mA, the specific capacitance of polyaniline nanofiber reaches 484.66Fg -1 , as the current density increases from 1mA to 10mA, the specific capacity decays by 15....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com