Polyaniline nanofiber/manganese dioxide nanorod composite material and preparation method thereof

A nanofiber, manganese dioxide technology, applied in the field of chemistry, can solve rare problems and achieve the effects of high product reproducibility, high stability and saving experimental reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

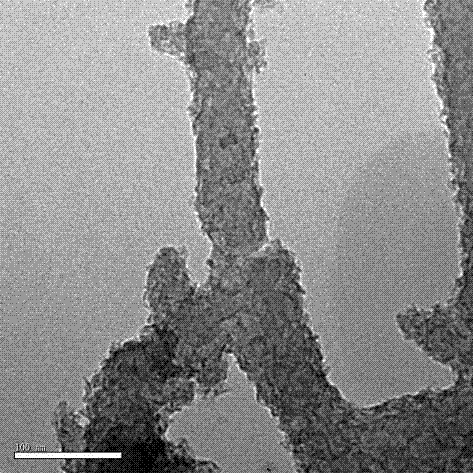

[0030] Embodiment 1: Preparation of polyaniline nanofiber / manganese dioxide nanorod composite material

[0031] (1) Raw material preparation: Aniline was distilled under reduced pressure before use, and stored in a 4°C refrigerator for later use. Potassium permanganate was prepared into a 0.10 mol / L aqueous solution with deionized water before use. Other chemical reagents were of analytical grade, and water was deionized water.

[0032] (2) Preparation of polyaniline nanofibers: Dissolve 0.30 ml aniline in 10 ml 1.0 mol / L HCl aqueous solution, and add 10 ml ammonium persulfate aqueous solution (0.18 g ammonium persulfate, 1.0 mol / L HCl aqueous solution) to it at one time , fully stirred at 25 °C for half a minute, and then reacted under static conditions for 6 hours, and the obtained polyaniline nanofibers had a particle size of 40-60 nm. Centrifuge the reaction system containing the precipitate to obtain a precipitate, then centrifuge and wash it with deionized water for mo...

Embodiment 2

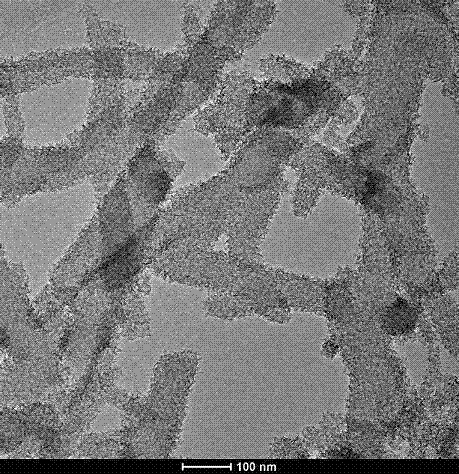

[0035] Embodiment 2: Preparation of polyaniline nanofiber / manganese dioxide nanorod composite material

[0036] (1) Raw material preparation: Aniline was distilled under reduced pressure before use, and stored in a 4°C refrigerator for later use. Potassium permanganate was prepared into a 0.10 mol / L aqueous solution with deionized water before use. Other chemical reagents were of analytical grade, and water was deionized water.

[0037] (2) Preparation of polyaniline nanofibers: Dissolve 0.30 ml aniline in 10 ml 1.0 mol / L HCl aqueous solution, and add 10 ml ammonium persulfate aqueous solution (0.18 g ammonium persulfate, 1.0 mol / L HCl aqueous solution) to it at one time , fully stirred at 25°C for half a minute, and then reacted under static conditions for 6 hours, and the obtained polyaniline nanofibers had a particle size of 40-60 nm. The reaction system containing the precipitate was centrifuged to obtain a precipitate, and then centrifuged and washed with deionized wate...

Embodiment 3

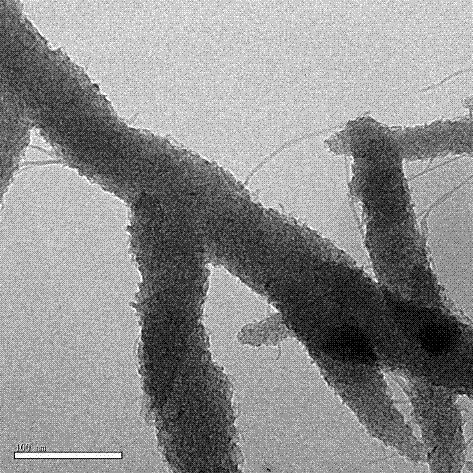

[0040] Embodiment 3; Preparation of polyaniline nanofiber / manganese dioxide nanorod composite material

[0041] (1) Raw material preparation: Aniline was distilled under reduced pressure before use, and stored in a 4°C refrigerator for later use. Potassium permanganate was prepared into a 0.01 mol / L aqueous solution with deionized water before use. Other chemical reagents were of analytical grade, and water was deionized water.

[0042](2) Preparation of polyaniline nanofibers: Dissolve 0.30 ml aniline in 10 ml 1.0 mol / L HCl aqueous solution, and add 10 ml ammonium persulfate aqueous solution (0.18 g ammonium persulfate, 1.0 mol / L HCl aqueous solution) to it at one time , fully stirred at 25 °C for half a minute, and then reacted under static conditions for 6 hours, and the obtained polyaniline nanofibers had a particle size of 40-60 nm. The reaction system containing the precipitate was centrifuged to obtain a precipitate, and then centrifuged and washed with deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com