Preparation of polystyrene/polyaniline composite microsphere supported catalyst

A supported catalyst, polystyrene microsphere technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as unreported research, etc. Achieve the effect of improving catalytic efficiency, high catalytic activity, and no safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

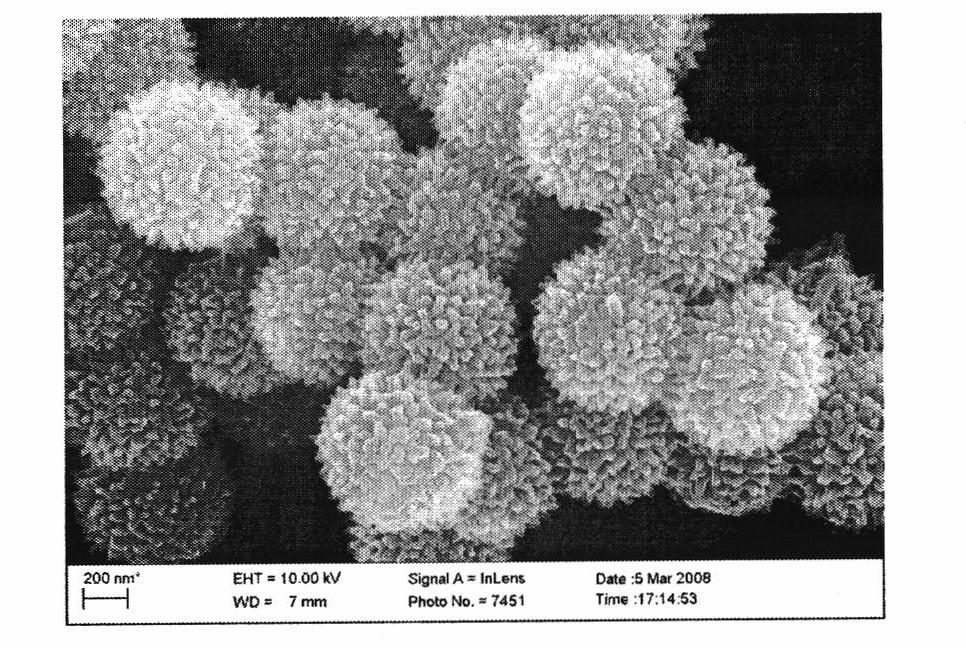

[0024] 1) Preparation of polystyrene microspheres

[0025] First, take 6 moles of deionized water and pass nitrogen at 70°C for 20 minutes, measure 0.1 mole of styrene and add it to the aqueous solution, and continue to pass nitrogen at 70°C for 20 minutes, weigh potassium persulfate (K 2 S 2 o 8) 0.0006 mole and dissolve it in 0.4 mole deionized water to form a solution and add it to the above-mentioned mixed system, keep the system temperature at 70°C, mechanically stir (300rpm) and react with nitrogen gas for 24h, the solution gradually becomes milky white during the reaction, and The reacted solution was centrifuged (9800 rpm, 10 min), washed three times with deionized water and absolute ethanol, and dried in vacuum to obtain the product.

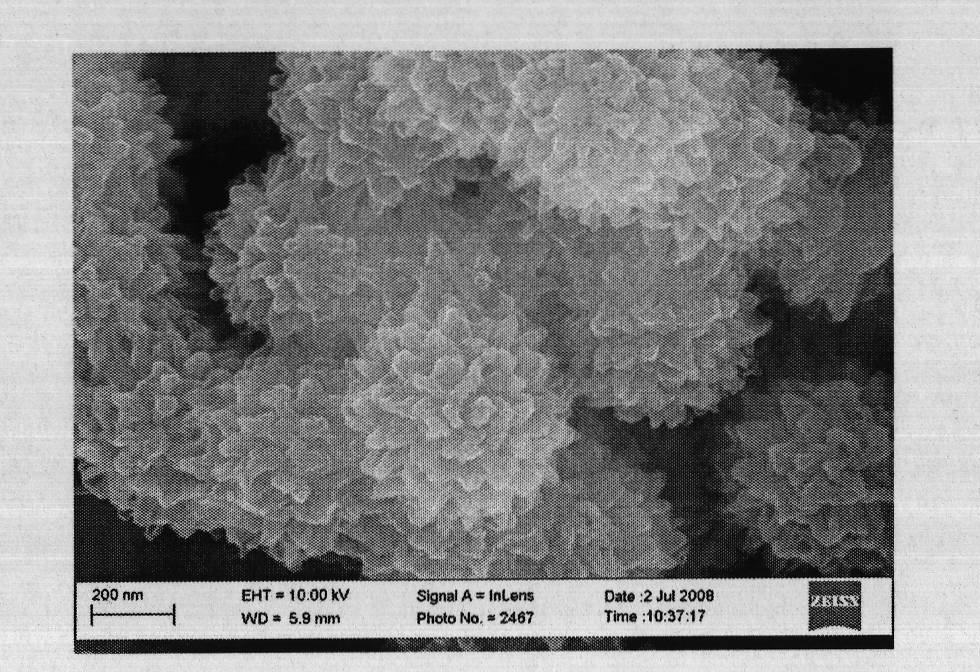

[0026] 2) Preparation of polystyrene / polyaniline composite microsphere carrier

[0027] First weigh 0.03 mol of polystyrene (PS) microspheres and dissolve them in 0.8 mol of deionized water to form a uniform emulsion. Use a syringe t...

Embodiment 2

[0036] 1) Preparation of polystyrene microspheres

[0037] First, take 10 moles of deionized water and pass nitrogen at 70°C for 20 minutes, measure 0.18 moles of styrene and add it to the aqueous solution, and continue to pass nitrogen at 70°C for 20 minutes, weigh potassium persulfate (K 2 S 2 o 8 ) 0.0009 mole and dissolve it in 0.8 mole deionized water to form a solution and add it to the above mixing system, keep the system temperature at 70 ° C, mechanically stir (300 rpm) and react with nitrogen gas for 24 hours, the solution gradually becomes milky white during the reaction, and the The reacted solution was centrifuged (9800 rpm, 10 min), washed three times with deionized water and absolute ethanol, and dried in vacuum to obtain the product.

[0038] 2) Preparation of polystyrene / polyaniline composite microsphere carrier

[0039] First weigh 0.08 mol of polystyrene (PS) microspheres and dissolve them in 1.2 mol of deionized water to form a uniform emulsion. Use a sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com