Polyaniline nano fiber and its preparing process

A nanofiber, polyaniline technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, etc., to achieve the effect of easy mass production, easy shape, and surface diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

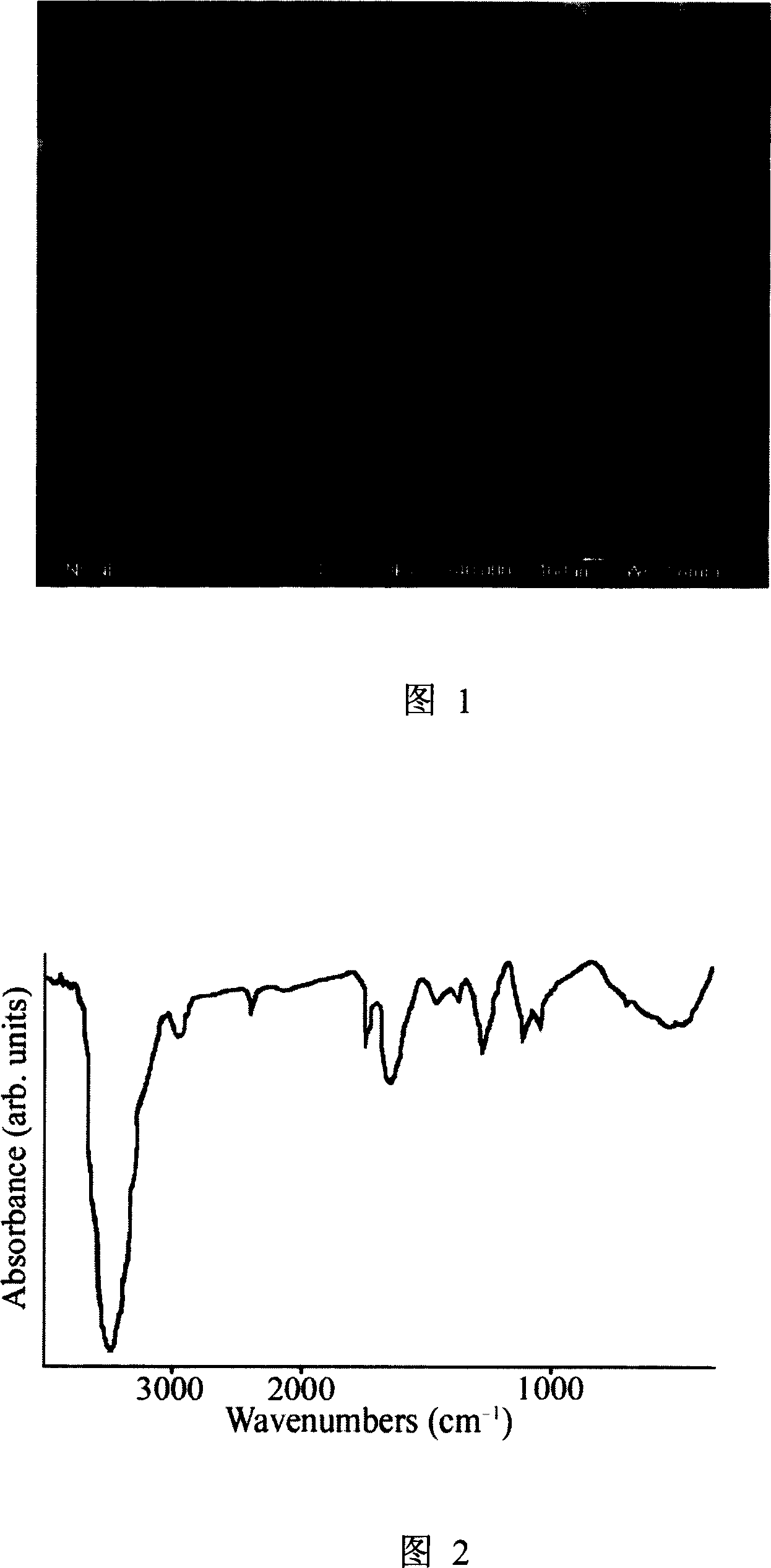

Image

Examples

specific Embodiment approach 1

[0018] A method for preparing polyaniline nanofibers by chemical oxidative polymerization with vanadic acid as an oxidant, comprising the following sequential steps:

[0019] (1) Fully mix vanadium pentoxide hydrochloric acid aqueous solution and aniline hydrochloric acid aqueous solution according to vanadium pentoxide and aniline molar ratio of 1:1, and control the molar concentration of hydrochloric acid in the mixed solution to be 0.1-0.5mol / L. React for 1 to 10 hours to obtain a polymer product;

[0020] (2) The above reaction product was centrifuged, washed three times with water and ethanol, and then dried at room temperature for 24 hours to obtain dark green polyaniline nanofibers.

specific Embodiment approach 2

[0021] A method for preparing polyaniline nanofibers by chemical oxidative polymerization with vanadic acid as an oxidant, comprising the following sequential steps:

[0022] (1) The vanadium pentoxide fluoroboric acid aqueous solution and the aniline hydrochloric acid aqueous solution are fully mixed according to the vanadium pentoxide and aniline molar ratio of 1:2, and the molar concentration of hydrochloric acid in the mixed solution is controlled to be 0.5-2mol / L, and then after 3-5 ℃ for 8 to 18 hours to obtain a polymer product;

[0023] (2) The above reaction product was centrifuged, washed with water to remove impurities, and dried at room temperature for 24 hours to obtain dark green polyaniline nanofibers.

specific Embodiment approach 3

[0024] A method for preparing polyaniline nanofibers by chemical oxidative polymerization with vanadic acid as an oxidant, comprising the following sequential steps:

[0025] (1) Fully mix vanadium pentoxide hydrochloric acid aqueous solution and aniline phosphoric acid aqueous solution according to the vanadium pentoxide and aniline molar ratio of 1:4, and control the molar concentration of hydrochloric acid in the mixed solution to be 0.5-2mol / L, and react at 0-5°C 10~24 hours, obtain polymerization product;

[0026] (2) The above reaction product was centrifuged, washed with water and ethanol to remove impurities, and dried at room temperature for 24 hours to obtain dark green polyaniline nanofibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com