Method of preparing lithium salt doping state polyaniline electrode material for super capacitor

A supercapacitor and polyaniline technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of unsatisfactory energy density and low specific capacitance value, and achieve low specific capacitance value, good pore structure, and high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

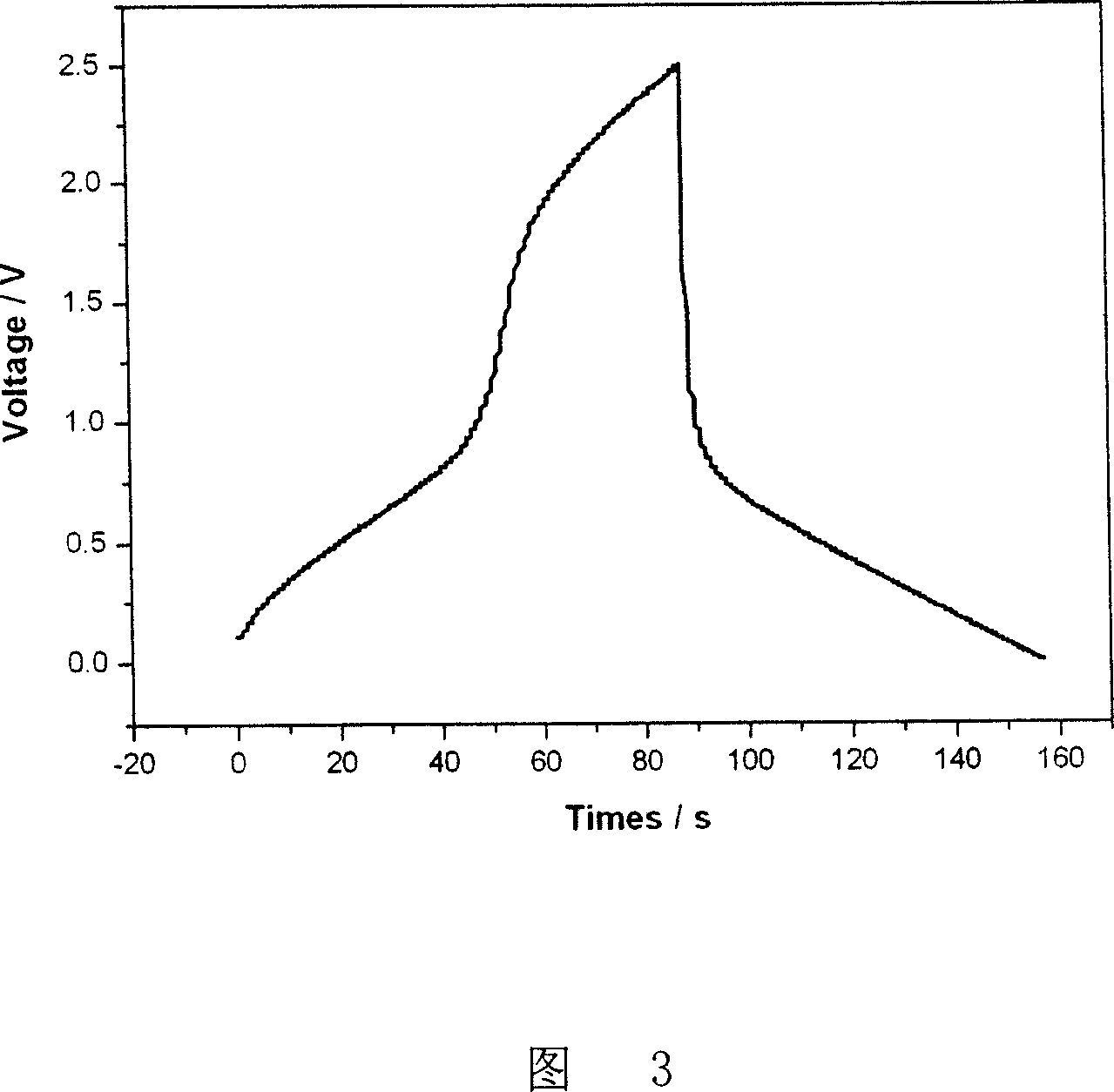

[0019] (1) Dissolve 0.93mL of aniline in 100mL of organic solvent CCl 4 Solution A was made in , and 0.57g of ammonium persulfate was dissolved in 100mL of 1mol / L hydrochloric acid to make solution B ([APS] / [AN]=1:4); (2) carefully mix solution A and solution B successively Move it into a reaction bottle and react at room temperature for 5 hours; (3) collect the product in solution B, wash the product with water, ethanol and acetone several times until the washing liquid is colorless; (4) vacuum dry the washed product at 40°C 48h, the polyaniline nanofiber material doped with hydrochloric acid was obtained; (5) the polyaniline nanofiber material was treated with 1mol / L ammonia water for 12h under stirring conditions, washed, and vacuum-dried at 80°C for 12h to obtain the intrinsic properties of polyaniline nanofibers. (6) under inert gas protection atmosphere, the polyaniline material in the intrinsic state was mixed with 1mol / L LiPF 6 Soak in EC / DEC / DMC (EC / DEC / DMC=1 volume ...

Embodiment 2

[0021] (1) 1.86 mL of aniline is dissolved in 100 mL of organic solvent toluene to form solution A, and 2.28 g of ammonium persulfate is dissolved in 100 mL of 2mol / L hydrochloric acid to form solution B ([APS] / [AN]=1: 2); (2) Carefully transfer solution A and solution B into the reaction flask in turn, and react at room temperature for 10 hours; (3) collect the product in solution B, wash the product with water, ethanol and acetone for several times, until the washing liquid is colorless (4) vacuum-dry the washed product at 60° C. for 24 hours to obtain a polyaniline nanofiber material doped with hydrochloric acid; (5) mix the polyaniline nanofiber material with 0.5mol / L sodium hydroxide solution under stirring conditions Treated for 24 hours, washed, and vacuum dried at 60°C for 24 hours to obtain the intrinsic state of polyaniline nanofibers; (6) the intrinsic state polyaniline material was dissolved in 1mol / L LiBF 4 Soak in EC / DEC (EC / DEC=1 volume ratio) solution for 48 ho...

Embodiment 3

[0023] (1) Dissolve 0.465mL of aniline in 100mL of organic solvent CH 2 Cl 2 Solution A was made in , and 0.285g of ammonium persulfate was dissolved in 100mL of 1mol / L perchloric acid to make solution B ([APS] / [AN]=1:1); (2) solution A and solution B Carefully move into the reaction bottle in turn, react at room temperature for 20h; (3) collect the product in solution B, wash the product with water, ethanol and acetone several times, until the washing liquid is colorless; (4) put the washed product at 80°C After vacuum drying for 12 hours, the polyaniline nanofiber material doped with perchloric acid was obtained. (5) Treat the polyaniline nanofiber material with a 0.2mol / L potassium hydroxide solution for 48h under stirring conditions, wash it, and dry it in vacuum at 80°C for 12h to obtain the intrinsic state of the polyaniline nanofiber; (6) in an inert gas Under the protective atmosphere, the intrinsic state polyaniline material was dissolved in 1mol / L LiClO 4 After so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com