Preparation method for high-concentration graphene-polyaniline nanofiber composite dispersion liquid and high-concentration graphene-polyaniline nanofiber composite film

A nanofiber and composite dispersion technology is applied in the field of preparation of high-concentration graphene-polyaniline nanofiber composite dispersions and composite films, and can solve problems such as difficulty in meeting application requirements, poor processability, and limited application of composite materials. Electrical conductivity improvement, high electrical conductivity, effect of suppressing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

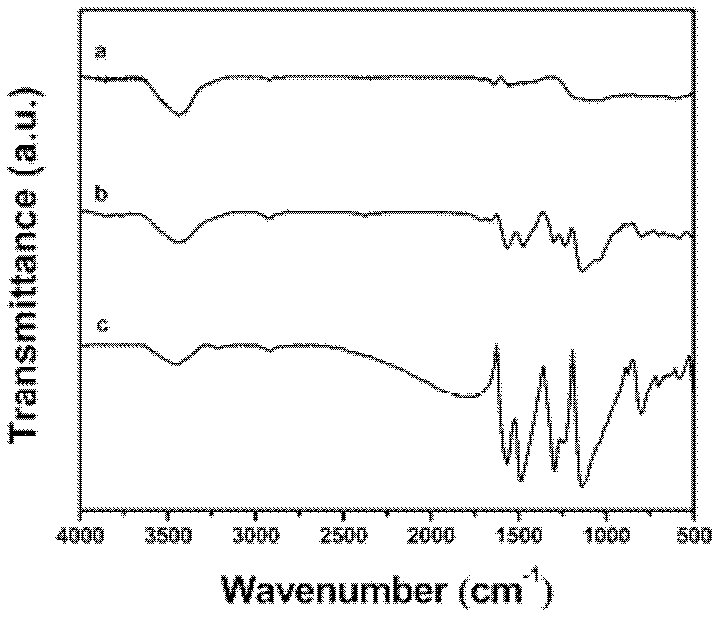

[0027] 1) Preparation of graphene oxide-polyaniline nanofiber dispersion

[0028] Add graphite oxide and polyaniline nanofibers into distilled water respectively, and obtain a stable graphene oxide dispersion with a concentration of 1 mg / mL and a polyaniline nanofiber dispersion with a concentration of 0.2 mg / mL after ultrasonic dispersion for 2 hours;

[0029] Add the polyaniline nanofiber dispersion dropwise to the graphene oxide dispersion according to the mass ratio of graphene oxide to polyaniline nanofiber is 3:1, after adding an appropriate amount of distilled water, continue ultrasonic dispersion for 2h and adjust the pH of the system to 4 , to obtain a graphene oxide-polyaniline nanofiber dispersion with a total concentration of 0.6 mg / mL;

[0030] 2) Preparation of high-concentration graphene-polyaniline nanofiber composite dispersion

[0031] Under the protection of nitrogen, put the graphene oxide-polyaniline nanofiber composite dispersion in a constant temperatur...

Embodiment 2

[0035] 1) Preparation of graphene oxide-polyaniline nanofiber dispersion

[0036] Add graphite oxide and polyaniline nanofibers into distilled water respectively, and obtain a stable graphene oxide dispersion with a concentration of 1.5 mg / mL and a polyaniline nanofiber dispersion with a concentration of 0.3 mg / mL after ultrasonic dispersion for 2 hours;

[0037] Add the polyaniline nanofiber dispersion dropwise to the graphene oxide dispersion according to the mass ratio of graphene oxide to polyaniline nanofiber is 4:1, after adding an appropriate amount of distilled water, continue ultrasonic dispersion for 2h and adjust the pH value of the system to 4 , to obtain a graphene oxide-polyaniline nanofiber dispersion with a total concentration of 0.8 mg / mL;

[0038] 2) Preparation of high-concentration graphene-polyaniline nanofiber composite dispersion

[0039] Under the protection of nitrogen, put the graphene oxide-polyaniline nanofiber dispersion in a constant temperature ...

Embodiment 3

[0043] 1) Preparation of graphene oxide-polyaniline nanofiber dispersion

[0044] Add graphite oxide and polyaniline nanofibers into distilled water respectively, and obtain a stable graphene oxide dispersion with a concentration of 0.8 mg / mL and a polyaniline nanofiber dispersion with a concentration of 0.2 mg / mL after ultrasonic dispersion for 2 hours;

[0045] According to the mass ratio of graphene oxide to polyaniline nanofibers is 2:1, add polyaniline nanofiber dispersion liquid dropwise to graphene oxide dispersion liquid, after adding appropriate amount of distilled water, continue ultrasonic dispersion for 2h and adjust the pH value of the system to be about 4. Obtain a graphene oxide-polyaniline nanofiber dispersion with a total concentration of 0.7 mg / mL;

[0046] 2) Preparation of high-concentration graphene-polyaniline nanofiber composite dispersion

[0047] Under the protection of nitrogen, put the graphene oxide-polyaniline nanofiber dispersion in a constant te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com