Method for preparing polyaniline and nano-fibre blend composite film

A nanofiber and polyaniline technology, applied in the field of ultrafiltration composite membrane preparation, can solve the problem of not seeing polyaniline nanocomposite membrane, etc., and achieve the effects of improved anti-membrane fouling ability, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

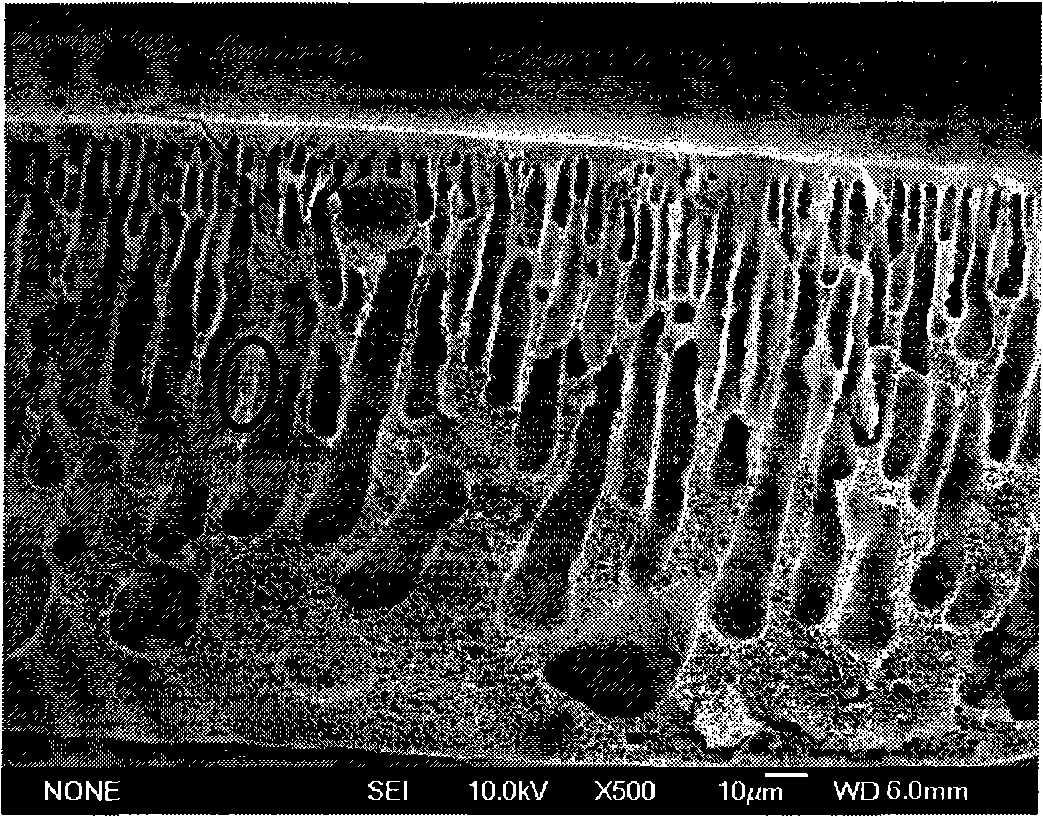

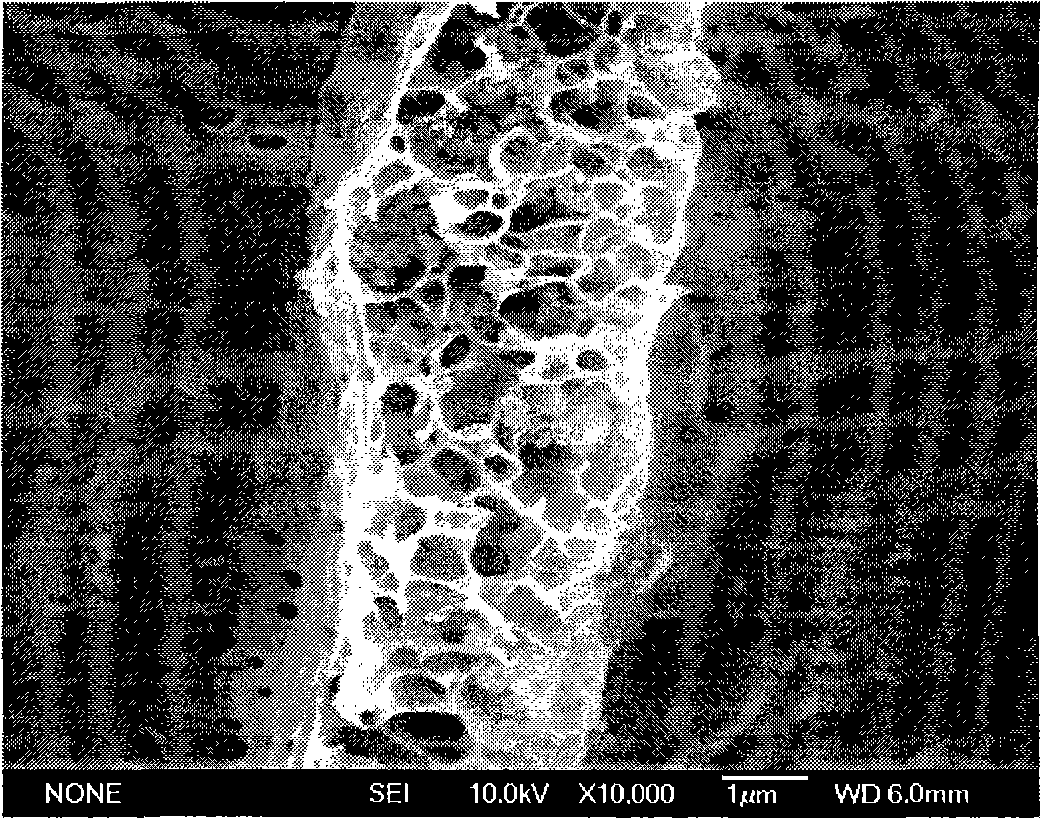

[0013] (1) Take 8.47ml of concentrated hydrochloric acid, dilute it to 100ml with deionized water, and prepare a 1M hydrochloric acid solution; measure 2.92ml of aniline and dissolve it in 100ml of 1M hydrochloric acid solution, make it into a hydrochloric acid solution of 0.32M aniline, and denote it as solution A; Dissolve 1.824g of ammonium persulfate in 100ml of 1M hydrochloric acid solution to prepare a 0.32M ammonium persulfate hydrochloric acid solution, denoted as solution B; quickly mix the two solutions A and B, shake for 30 seconds, and let stand for 4~ 6 hours; the polyaniline nanofibers were separated by suction filtration with a 0.22 μm microporous membrane, washed with deionized water, methanol and concentrated hydrochloric acid, and dried in vacuum at 25°C for 4 hours to obtain polyaniline nanofibers with an average diameter of 43 nm and an average length of 259 nm. fiber.

[0014] (2) Weigh 0.15 g of polyaniline nanofibers, place them in 8.35 g of solvent N,N-...

Embodiment 2

[0017] Polyaniline nanofibers were prepared according to step (1) in Example 1; 0.015 g of polyaniline nanofibers were weighed, placed in 8.485 g of solvent N,N-dimethylacetamide (DMAc), and subjected to magnetic stirring at 120 r / min and Under the condition of ultrasonic frequency 45Hz, the nanofibers are uniformly dispersed; 1.50g of polysulfone is added to the dispersion liquid of polyaniline nanofiber-N,N-dimethylacetamide, and stirred until it is completely dissolved to obtain 10g of casting liquid, which is left to stand for 8 For more than 1 hour, remove the bubbles in the casting liquid; in the environment of temperature 25 ℃, relative humidity 60%, scrape the film on the glass plate with a film scraper, control the thickness of the film liquid to 300 μm; after 30 seconds, immerse the glass plate in The polyaniline nanofiber blended composite membrane was obtained by placing it in deionized water at 25° C. for more than 4 hours, which was immersed in pure water for pres...

Embodiment 3

[0020] Polyaniline nanofibers were prepared according to step (1) in Example 1; 0.12 g of polyaniline nanofibers were weighed and placed in a solvent of 8.68 g of dimethylformamide. The fibers are uniformly dispersed; 1.20 g of polysulfone is added to the dispersion liquid of polyaniline nanofiber-dimethylformamide, and stirred until completely dissolved to obtain 10 g of a casting liquid, which is allowed to stand for more than 8 hours to remove bubbles in the casting liquid; Under the environment of temperature 24°C and relative humidity 45%, use a doctor blade to scrape the glass plate to form a film, and control the thickness of the film liquid to 300μm; after 30 seconds, immerse the glass plate in deionized water at 24°C and let it stand for more than 4 hours , to obtain a polyaniline nanofiber blended composite membrane, which was immersed in pure water for preservation.

[0021] The obtained polyaniline nanofiber blended composite membrane has a pure water flux of 344 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com