Anti-floating structure for cast-in-place concrete gbf hollow floor slab and method thereof

A hollow floor slab and concrete technology, applied in the field of building construction, can solve problems such as floating of GBF thin-walled pipes, and achieve the effect of avoiding rusting and solving the problem of consuming a large amount of iron wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

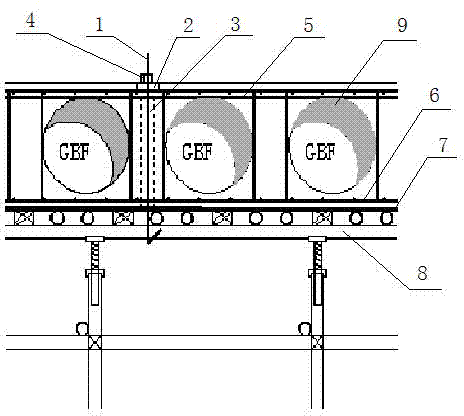

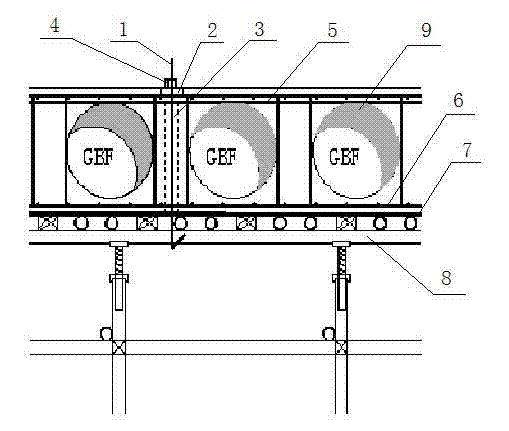

[0012] For further describing content, characteristic and effect of the present invention, in conjunction with accompanying drawing, make following explanation:

[0013] figure 1 Shown is a schematic cross-sectional view of the structure of the present invention.

[0014] The present invention includes anti-floating steel bars 5, lower layer steel bars 6, templates 7, template brackets 8, and GBF thin-walled pipes 9.

[0015] The GBF thin-walled pipe 9 is located between the anti-floating steel bars 5 and the lower layer of steel bars 6, and there are at least two horizontally arranged anti-floating steel bars 5 in the longitudinal direction of each section of the GBF thin-walled pipe 9. The GBF thin-walled pipe 9, the anti-floating steel bars 5 And the lower reinforcement 6 is integrally positioned on the template 7, and the template 7 is positioned on the template bracket 8.

[0016] A plurality of through holes are provided in the gaps between the GBF thin-walled tubes 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com