Anti-floating processing method and apparatus of coated controlled release fertilizer

A technology of coated controlled-release fertilizer and treatment method, which is applied in the field of anti-floating treatment of coated controlled-release fertilizer, can solve the problems of resource waste, floating away, unfavorable uniform fertilization, etc., and achieve the effect of convenient operation and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

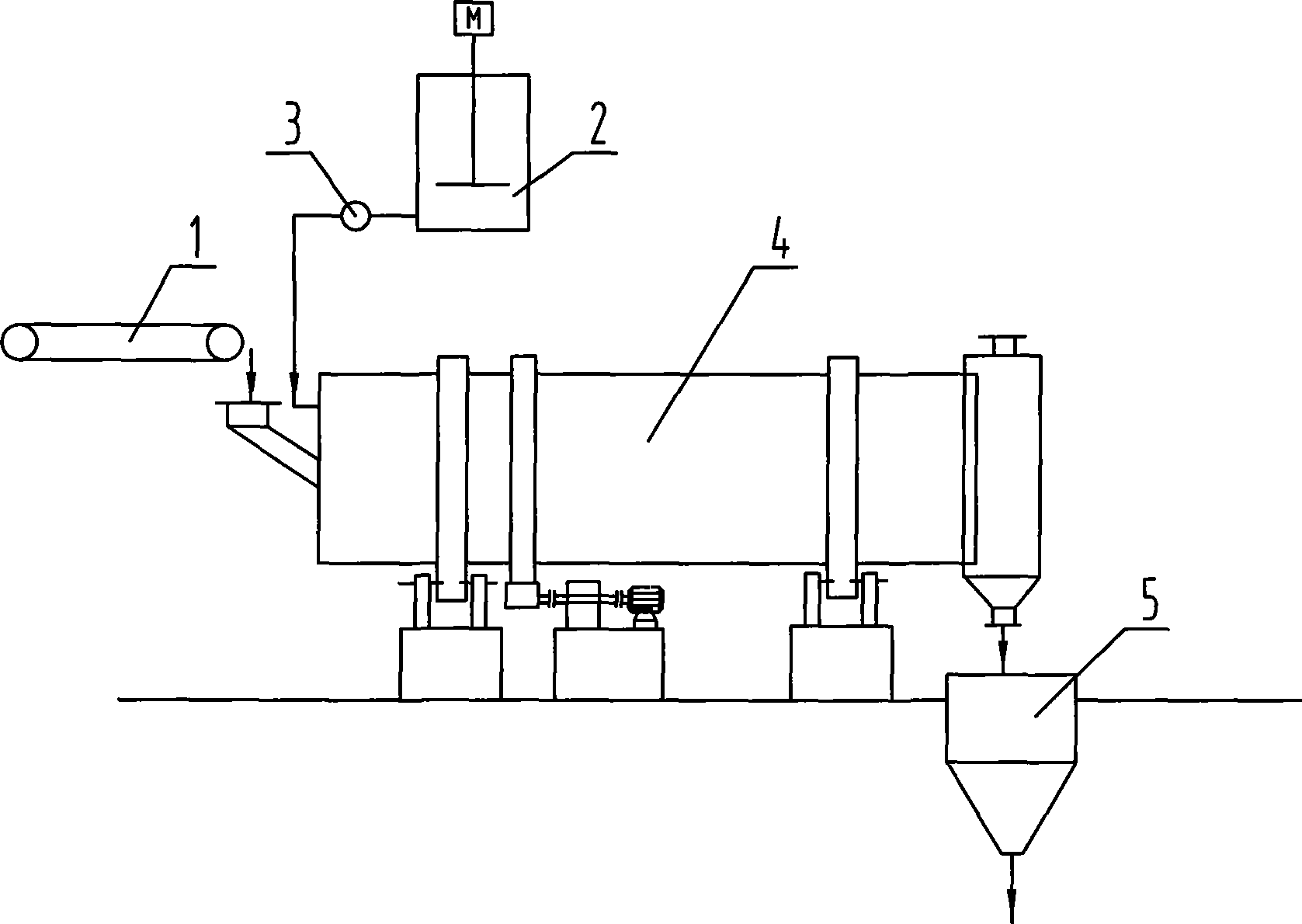

[0019] Depend on figure 1 It can be seen that the special device for realizing the anti-floating treatment method of controlled-release fertilizer in the present invention includes: quantitative feeder 1, solution preparation device 2, flowmeter 3, rotating drum 4 and finished product silo 5, and described quantitative feeder 1 Connected to the feed port of the drum 4, the solution preparation device 2 is connected to the drum 4 through the flow meter 3, and the discharge port of the drum 4 is connected to the finished product bin 5.

[0020] The solution preparation device 2 can be a pressure tank plus an air compressor, or a storage tank plus a liquid pump; the quantitative feeder 1 includes a belt scale and a conveyor belt.

Embodiment 2

[0022] Utilize the device described in embodiment 1 to carry out the anti-floating treatment of the controlled-release fertilizer. The anti-floating agent uses water-soluble azone, and absolute ethanol is used as diluent. The solution configuration device 2 adopts a pressure tank and an air compressor, and the dosage per ton of product is respectively 0.5kg, 1kg, 2kg, and 3kg. The specific operation steps are as follows:

[0023] Step 1: Add 50kg of water-soluble azone and 5kg of absolute ethanol into the pressure tank and mix well, close the filling valve, turn on the air compressor, and adjust the pressure of the pressure tank to 1-2MPa.

[0024] Step 2: Start the quantitative feeder 1, the coated slow-release fertilizer is transported into the drum 4 through the conveyor belt, preheat the controlled-release fertilizer to 55-75°C, open the liquid spray valve, adjust the flow rate of the flow meter 3, and put the water-soluble Azone is sprayed onto the fertilizer granules, a...

Embodiment 3

[0027] Utilize the device described in embodiment 1 to carry out the anti-floating treatment of the controlled-release fertilizer. The anti-floating agent uses sodium dodecylsulfonate solution. The solution configuration device 2 adopts a storage tank and a liquid pump, and the dosage per ton of product is respectively 0.5kg, 1kg, 2kg, and 3kg. The specific operation steps are as follows:

[0028] Step 1: Add 50kg of sodium dodecylsulfonate solution into the storage tank.

[0029] Step 2: Start the quantitative feeder 1, the coated slow-release fertilizer is transported into the drum 4 through the conveyor belt, preheat the controlled-release fertilizer to 55-75°C, turn on the liquid pump and spray valve, adjust the flow rate of the flow meter 3, The sodium dodecylsulfonate solution is sprayed onto the fertilizer granules, and as the drum 4 rotates, the fertilizer granules move continuously to complete the anti-floating treatment.

[0030] The third step: after the anti-floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com