Method for rapidly culturing denitrifying granular sludge

A technology of nitrifying granules and denitrifying bacteria is applied in the field of water treatment, which can solve the problems of sludge floating and sludge bed channeling, and achieves the effects of low cost, simple structure and favorable promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

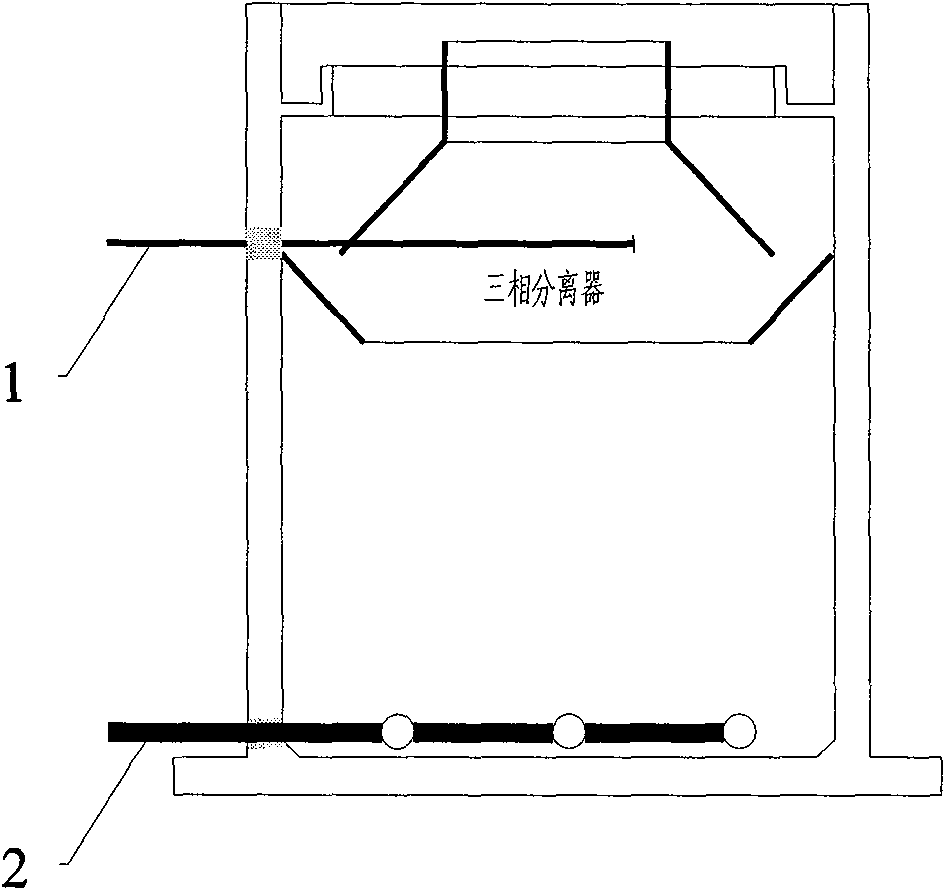

Image

Examples

Embodiment 1

[0013] Example 1 , Denitrification Granular Sludge Cultivation

[0014] A chemical company produces ammonia nitrogen wastewater. After testing, its C / N (COD / NO 3 -N) is relatively low, and the nitrate concentration in the effluent after the secondary biochemical process is relatively high. Therefore, it is necessary to perform denitrification treatment on the secondary effluent. Granular sludge, the specific cultivation process is as follows:

[0015] 1.1. Sludge pretreatment

[0016] Take about 20 tons of urban sewage plant sludge and pour it into the USB pool (the effective volume is 200m 3 ), carry out hydrolysis and fermentation treatment at 55°C, and add 7-8kg of potassium nitrate and 2-3kg of methanol every day at the same time for pre-acclimation. The sludge is in the form of fine particles, and there are signs of gas production on the surface, indicating that the pretreatment work is over (the same below).

[0017] 1.2. Granular sludge cultivation

[0018] After...

Embodiment 2

[0023] Example 2 , Denitrification Granular Sludge Cultivation

[0024] The concentration of nitrate in groundwater in a certain area is as high as 150mg / L, seriously exceeding the standard. Therefore, it needs to be denitrified. The process is as follows:

[0025] 2.1. Sludge pretreatment

[0026] Put 3 tons of flocculent sludge under the sun, cover it with a plastic shed, and carry out hydrolysis and fermentation at 40°C. At the same time, add 1 kg of potassium nitrate and 0.6 kg of glucose every day for domestication.

[0027] 2.2. Granular sludge cultivation

[0028] Connect the pretreated sludge to USB (effective volume is 20m 3 ), the treated water volume is 500m 3 d -1 , the influent load is 0.5-5.0gNO 3 -N·L -1 d -1 , using glucose as the carbon source, adjusting C / N to 3.5-4.0.

[0029] Start the system for granular sludge cultivation, and observe during the cultivation process, the results are as follows:

[0030] After the reactor was filled with water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com