Method for controlling quality of tunnel pipe sheet built by using shield method and pipe sheet structure

A technology of tunnel segment and shield method, which is applied in the field of tunnel lining quality control, can solve problems such as alignment deviation, inconvenient operation, and insufficient strength of segment 60, and achieve the effect of improving accuracy, efficiency and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

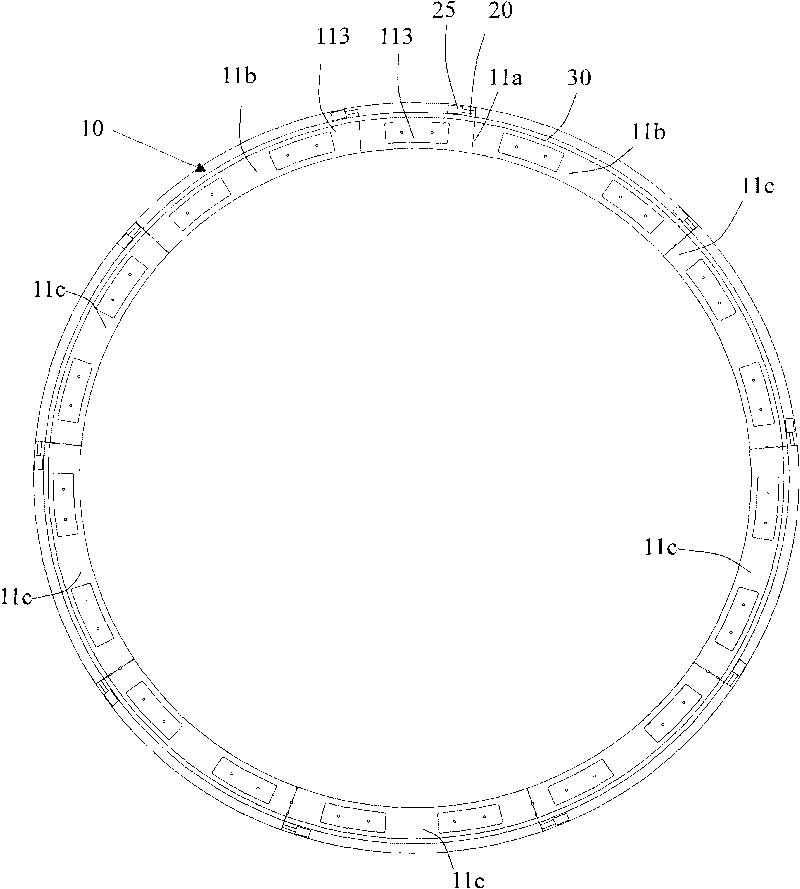

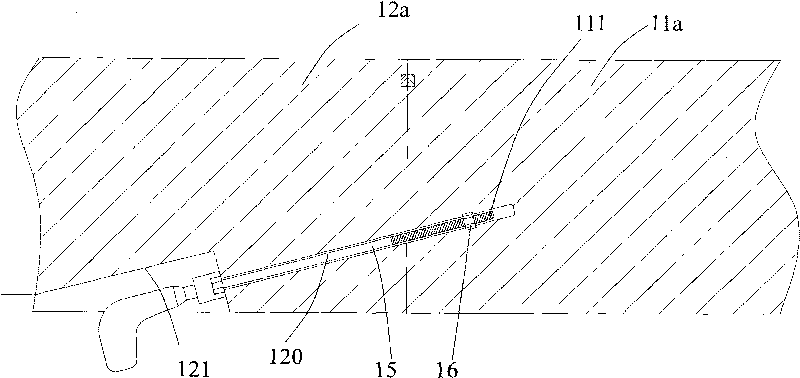

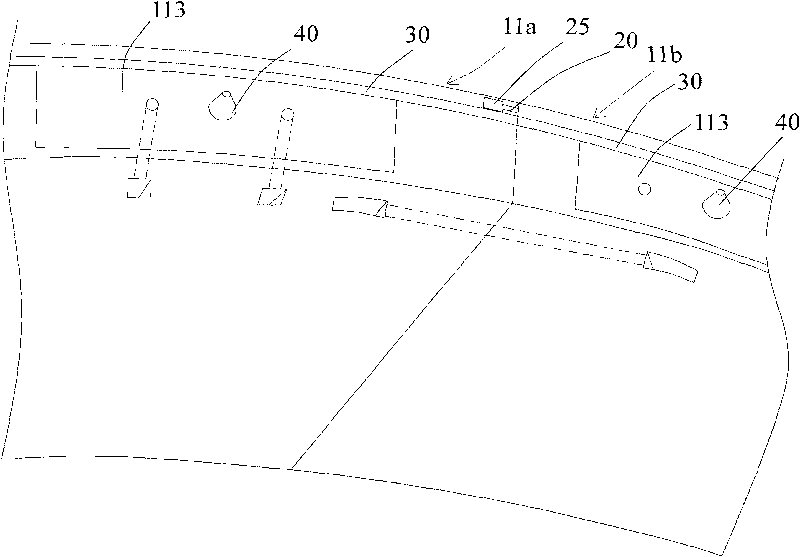

[0045] The quality control of the ultra-large diameter shield construction segments of the present invention will be further described in detail in conjunction with specific projects below. In the following description, the side where the shield machine digs forward is defined as the front end, and the opposite end is defined as the rear end. Take the Shanghai Yangtze River Tunnel Project as an example. The Shanghai Yangtze River Tunnel Project is a tunnel project connecting Wuhaogou in Pudong and Changxing Island. It is a super-large transportation construction project along the Yangtze River Estuary in my country. The Yangtze River Tunnel Project is divided into the east line and the west line. The lengths of the two lines are 7471.65m and 7469.36m respectively. The maximum slope of the tunnel is 2.9%, and the minimum plane curvature radius is 4000m. The tunnel is constructed by the shield method, and the shield used is a super muddy water shield with a diameter of 15.43m ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com