Active drainage anti-floating segment and lining structure

A technology for drainage pipes and floating segments, which is applied in the direction of shaft lining, tunnel lining, drainage, etc., can solve the problems of segment floating and inability to effectively transmit stress, so as to prevent the segment from floating, increase the anti-floating ability, and improve filling rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

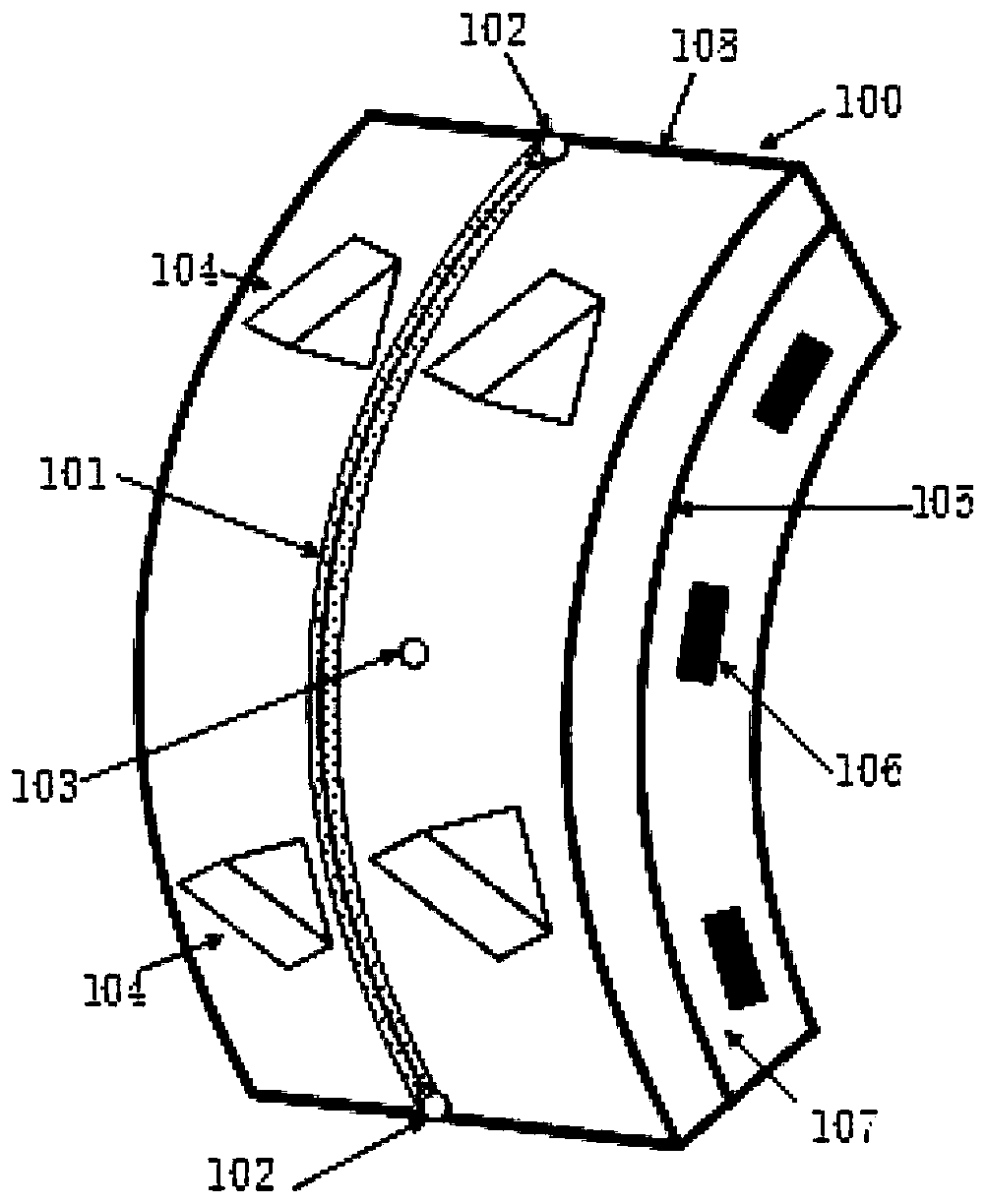

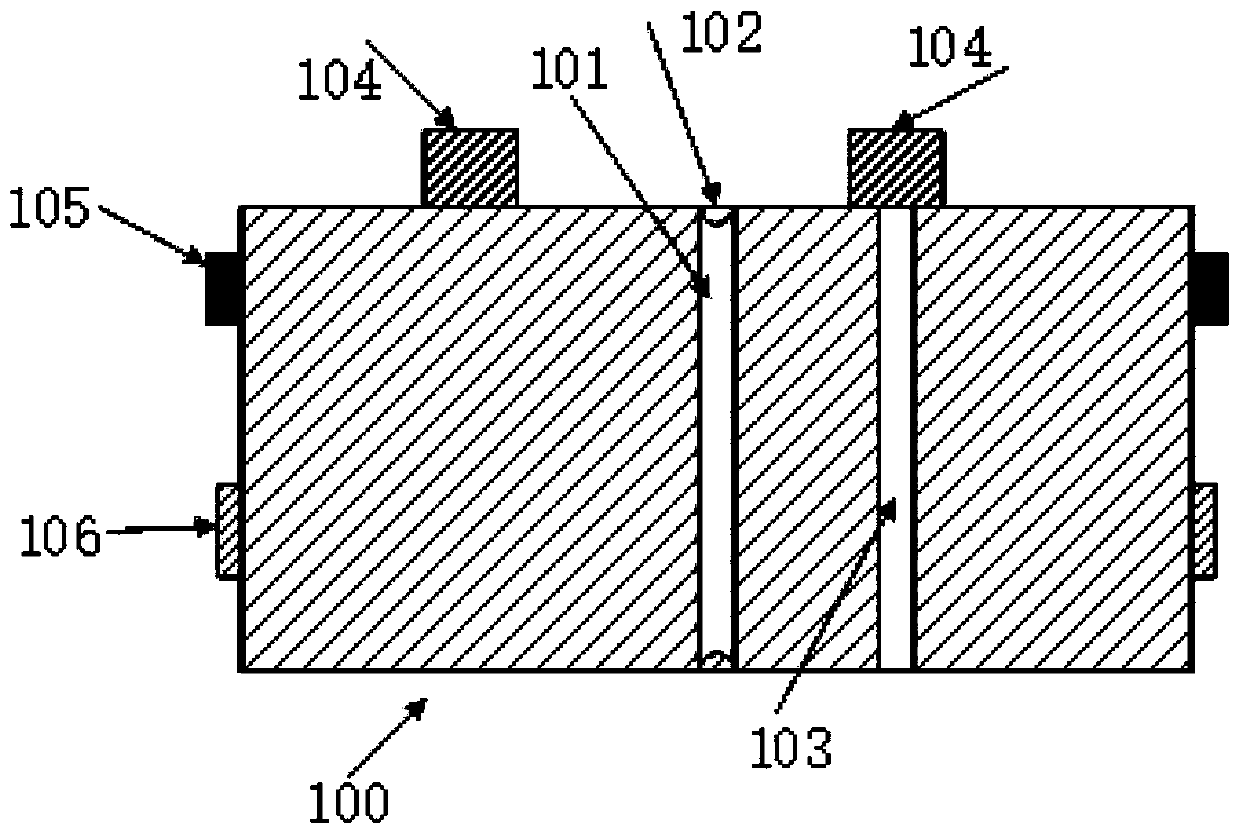

[0020] The main structure of the active drainage anti-floating segment involved in this embodiment includes the segment body 100, the drain pipe 101, the drain hole 102, the grouting hole 103, the corner block 104, the water stop strip 105, the anti-collision strip 106, the arc Shaped side end face 107, rectangular side end face 108; The arc length direction of the arc-shaped outer surface of the arc-shaped sheet-shaped segment body 100 is provided with a semicircular groove, and a drain pipe 101 is embedded in the groove, and the drain pipe 101 top is provided with Dense tiny holes, so that the excess water precipitated after grout hardening can be discharged, provide grout filling and hardening space for secondary grouting, and improve the filling rate and compactness of grout; the two ends of the drain pipe 101 are provided with drain holes 102, The grouting water is discharged from the drain hole 102; the highest part of the arc-shaped outer surface of the segment body 100 ...

Embodiment 2

[0023] Such as figure 1 and figure 2 As shown, the active drainage anti-floating segment includes a segment body 100, and the segment body includes a drain pipe 101 located outside the arc-shaped outer surface. Among them, the segment body 100 is an arc-shaped sheet with a certain thickness, and the drain pipe 101 is used to discharge the excess water precipitated after the grouting grout is hardened, so as to provide a grout filling and hardening space for the secondary grouting, so as to improve The filling rate and compactness of the slurry.

[0024] Specifically, another example figure 1 and figure 2 As shown, the drain pipe 101 is arranged along the arc length direction of the arc-shaped outer surface of the segment body 100, the drain pipe 101 is a semicircular structure, the arc-shaped outer surface of the segment body 100 is provided with a semicircular groove, and the drain pipe 101 is embedded in the groove of the arc-shaped outer surface, and cast together wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com