A kind of composite pile ready-mixed fluid solidified soil slurry and preparation method thereof

A technology of solidified soil and composite piles, which is applied in the field of building material preparation, can solve the problems of inconsistent shrinkage, cracks and easy sinking of pre-mixed fluid solidified soil, so as to improve product safety and reduce or efflorescence phenomenon , Improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

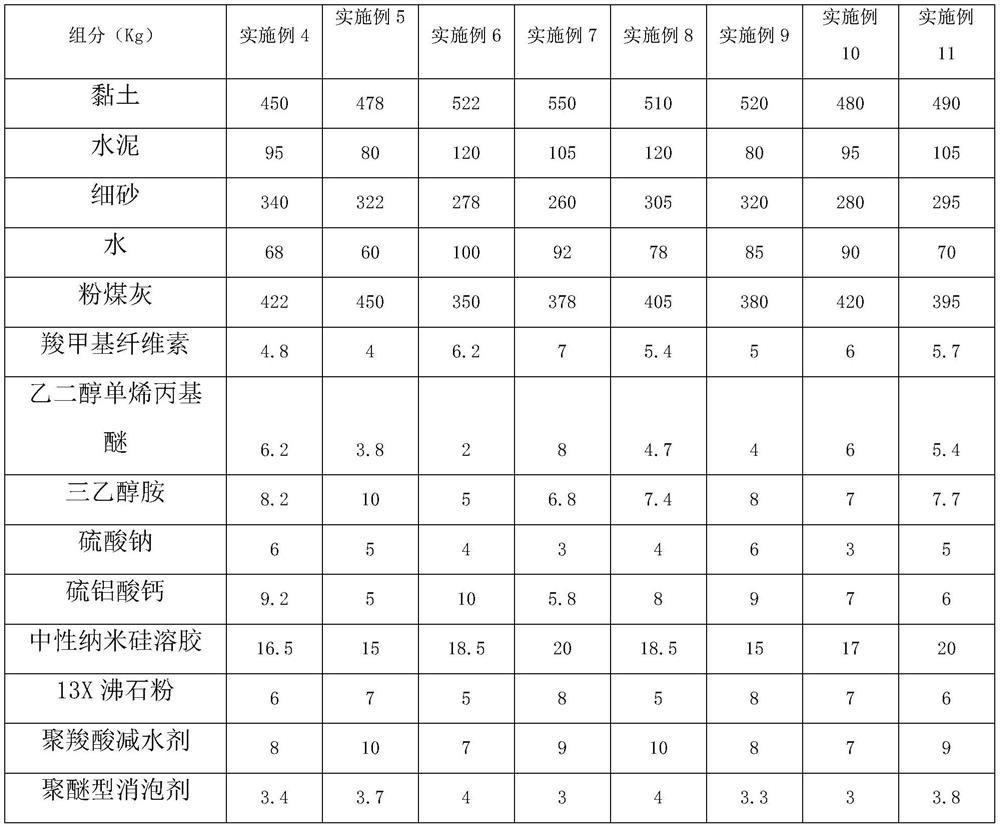

[0036] Embodiment 1: A preparation process of composite pile ready-mixed fluid solidified soil slurry, comprising the following steps:

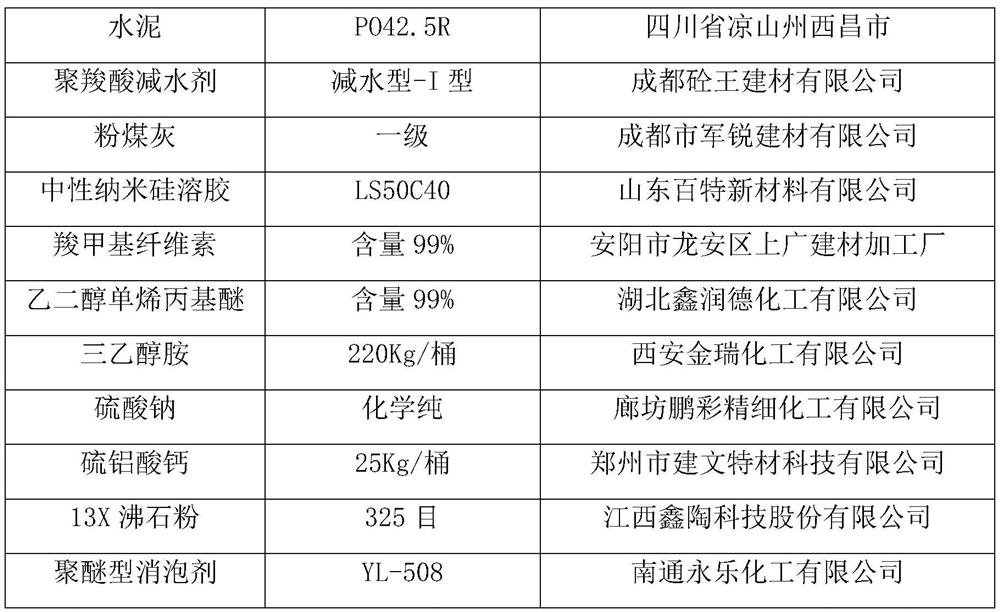

[0037] Preparation of S1 modifier: Weigh 5.5Kg of carboxymethyl cellulose, add 5Kg of ethylene glycol monoallyl ether, 8Kg of polycarboxylate water reducer and 3.5Kg of polyether defoamer, and mix evenly to obtain modified sex agent.

[0038] S2 activator preparation: Weigh 7.5Kg triethanolamine, add 5Kg sodium sulfate, 7Kg calcium sulfoaluminate and 18Kg neutral nano-silica sol (sodium oxide content 0.15%, silicon dioxide content 40%, the rest is water, neutral nano-silica sol The median particle diameter (D50) of the silica sol is 44.3nm), and then 6Kg of 13X zeolite powder was added and mixed uniformly to prepare the activator.

[0039]Preparation of S3 liquid solidified soil slurry: sieve the clay with a sieve with a hole diameter of 20 mm, and select clay with a particle size not greater than 20 mm. Screen the fine sand with a sieve wi...

Embodiment 2

[0041] The difference between Example 2 and Example 1 is that the neutral nano-silica sol is not added in Example 2, and the others are consistent with Example 1.

Embodiment 3

[0043] The difference between Example 3 and Example 1 is that Example 3 does not add 13X zeolite powder, and the others are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com