Metal-based hollow-ball composite foam material and preparation method thereof

A metal-based composite and composite foam technology, applied in the field of foam metal, can solve problems such as lack of metal-based composite foam, and achieve the effects of low cost, simple operation steps, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

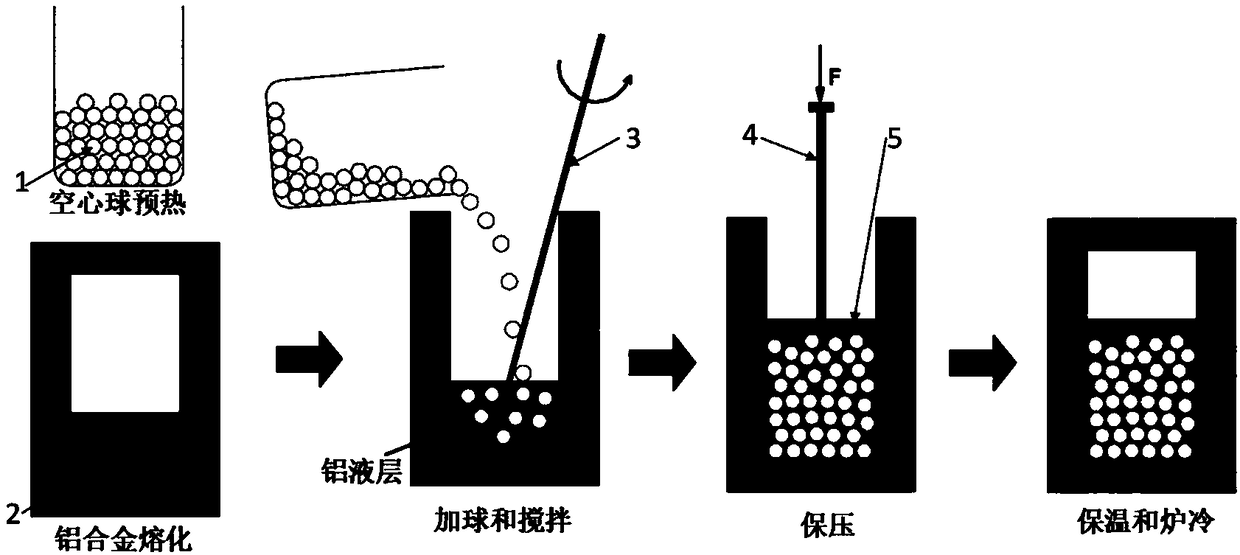

Method used

Image

Examples

Embodiment 1

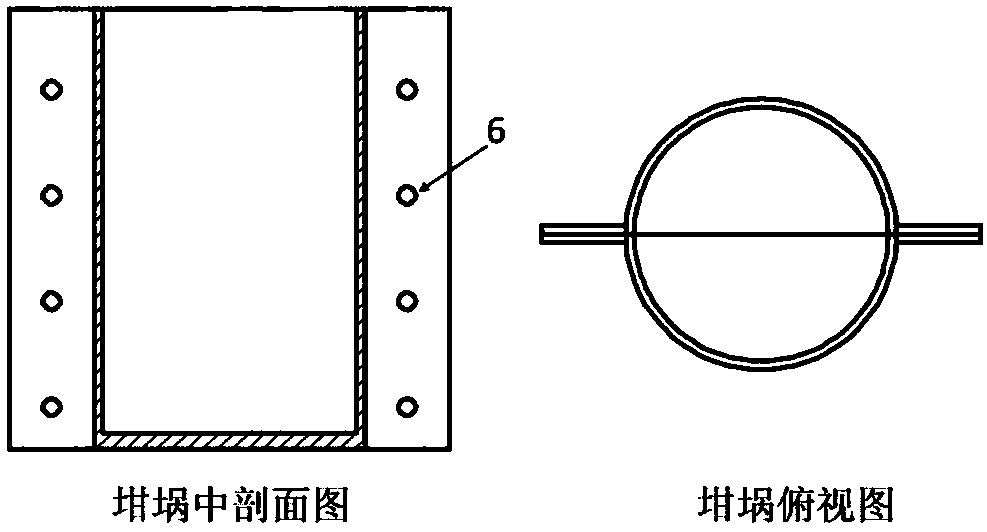

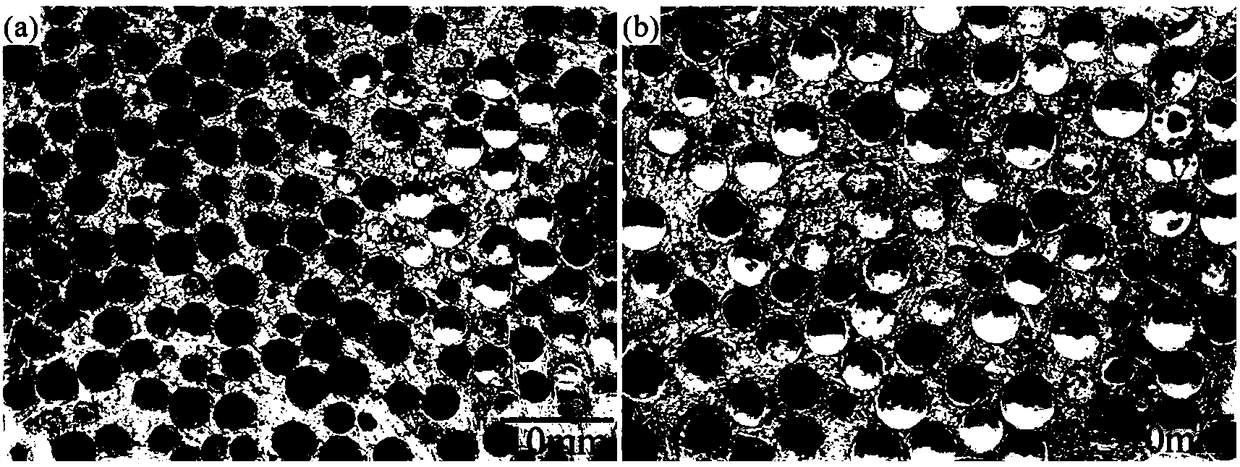

[0034]Alumina hollow balls of 3.5-4mm and A356 aluminum alloy are selected as raw materials. After measurement, the average density of 3.5-4mm aluminum oxide hollow spheres is 1.027g / cm 3 , with an average wall thickness of 174 μm. use as figure 2 The crucible shown prepares syntactic foam samples with a diameter of 60 mm and a height of 50 mm.

[0035] Place 155g (40% of the total sample volume should be 152g in theory in theory, and the actual melting aluminum will be a little more) in the crucible, considering the loss of aluminum such as subsequent removal of surface oxide skin, and place the crucible in a resistance furnace. Gradually raise the temperature to 690°C and keep it at 690°C. At the same time, in another resistance furnace, 90g (60% of the total sample volume should be 87g in theory, considering that there may be a little loss when adding balls, so the actual preheated balls will be a little more) of 3.5-4mm The aluminum oxide hollow spheres and the pressin...

Embodiment 2

[0038] Compared with the previous embodiment, only the particle size of the hollow spheres in this embodiment has changed, so the preparation process will not be repeated here. Alumina hollow balls of 4.5-5mm and A356 aluminum alloy are selected as raw materials. After measurement, the average density of 4.5-5mm aluminum oxide hollow spheres is 0.938g / cm 3 , with an average wall thickness of 326 μm. use as figure 2 The crucible shown prepares syntactic foam samples with a diameter of 60 mm and a height of 50 mm. The mass of the A356 aluminum alloy initially melted in the crucible is still 155g, and the mass of the preheated 4.5-5mm alumina hollow ball is 83g. The process of preheating hollow spheres, melting aluminum—adding hollow spheres and stirring—pressurizing—insulating heat—cooling is the same as in Example 1.

[0039] The cross-sectional morphology of the prepared aluminum-based hollow sphere composite foam is as follows: image 3 (b) shown. After testing, the ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com