High-concentration straw methane fermentation equipment

A biogas fermentation and high-concentration technology, applied in the energy field, can solve the problems of low material concentration, low input-output ratio, and low utilization rate of raw materials, so as to increase the concentration of fermentation materials, prevent straw from floating and encrusting, and increase volumetric gas production rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

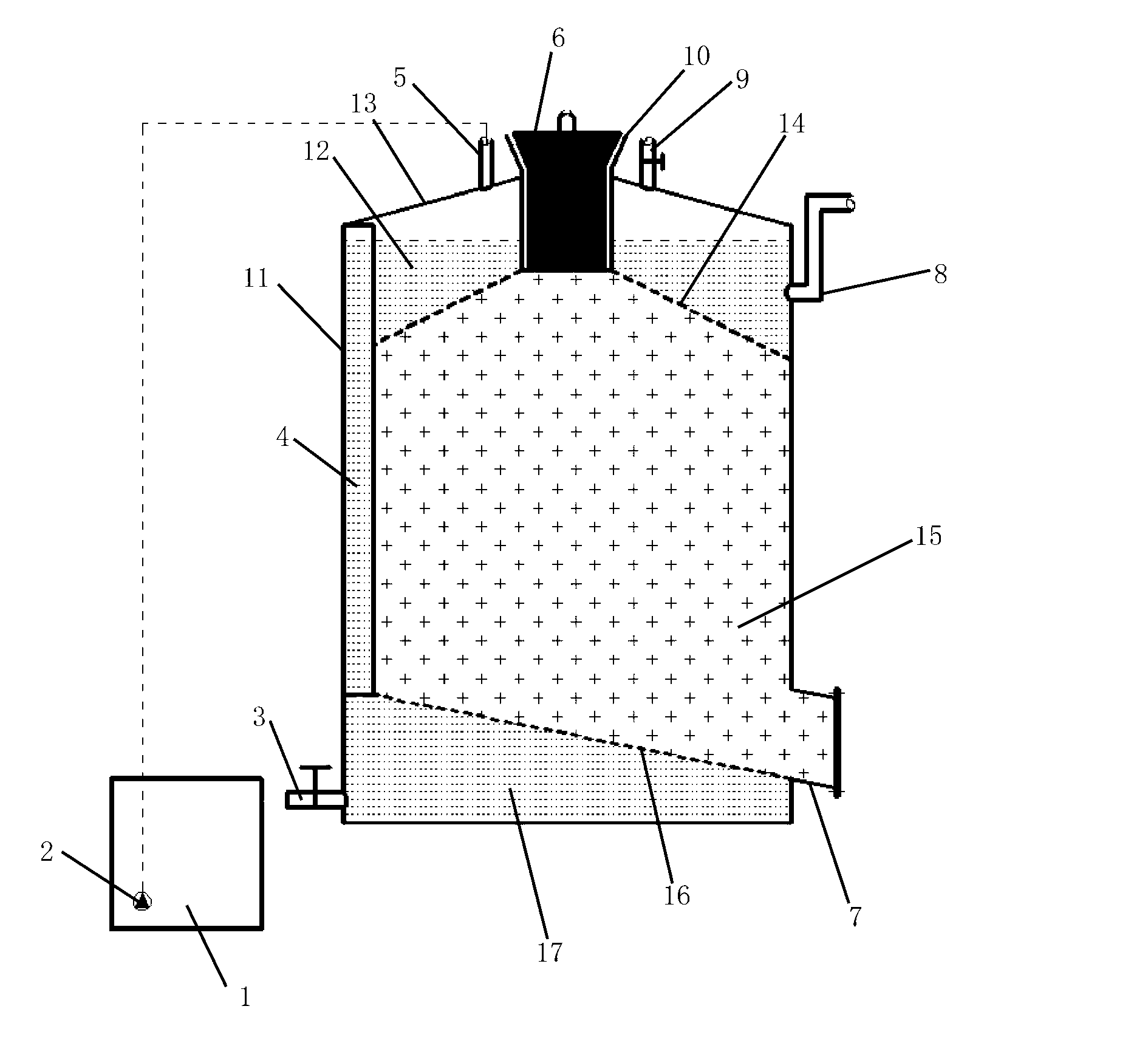

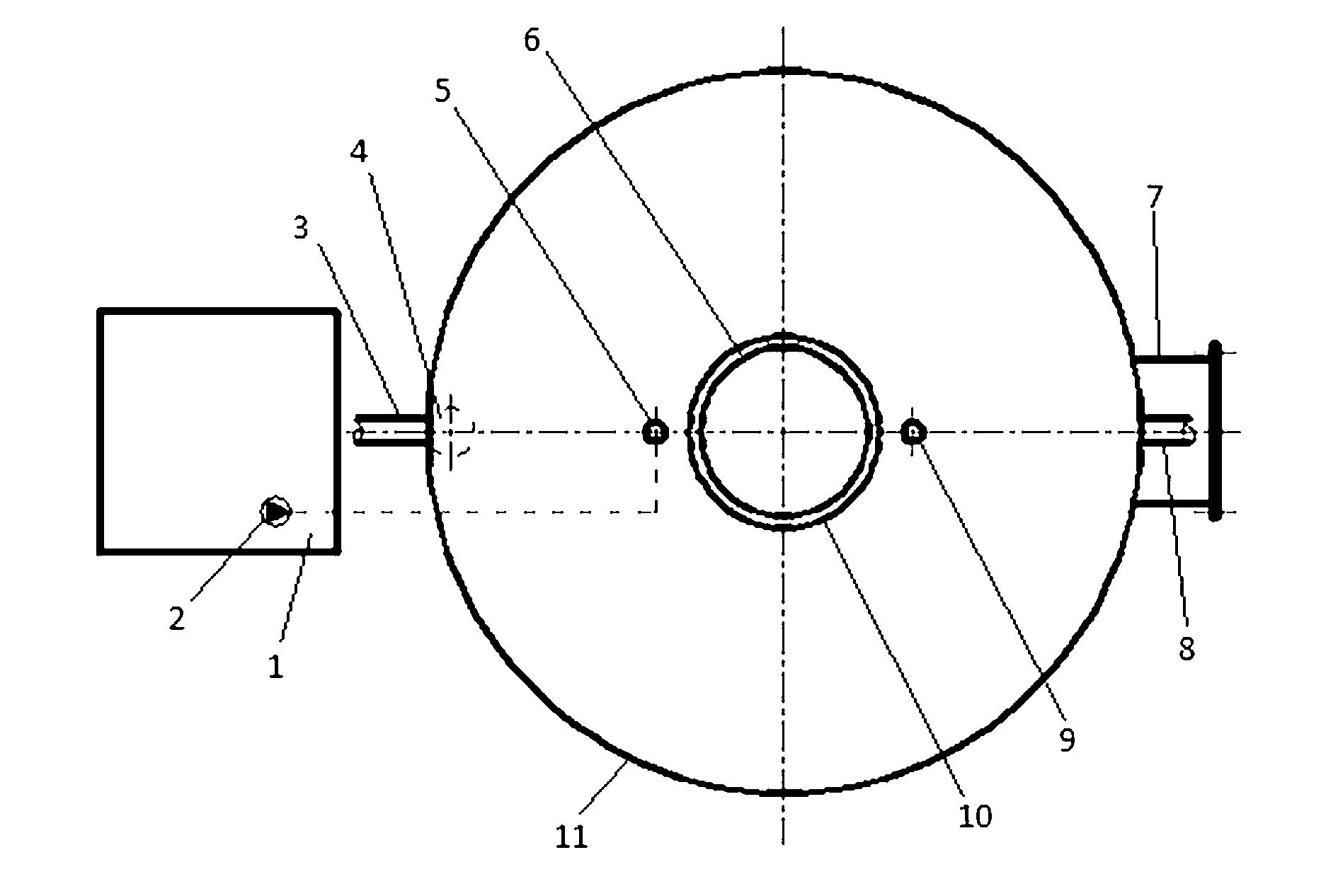

[0020] The high-concentration straw biogas fermentation device in this example is as follows: figure 1 and figure 2 As shown, it is composed of a fermenter 11 and a liquid storage unit 1. The fermenter 11 is a vertical tank body. The top of the tank body is provided with a feed pipe 10 and a biogas nozzle 9 with a valve. The slag mouth 7 is characterized in that a gravity pusher 6 is installed in the feed pipe 10, and the feed pipe 10 is closed by the gravity pusher 6; the top of the tank body is provided with a return nozzle 5, and the return nozzle 5 passes through the circulation The pump 2 is connected with the liquid storage unit 1; the upper part of the tank is provided with an overflow pipe 8, the low point of the overflow pipe 8 is higher than the outlet of the feed pipe 10, and the high point is lower than the inlet of the biogas nozzle 9; the upper part of the tank is installed There is a round table-shaped slag retaining ring plate 14, the upper end of the slag re...

Embodiment 2

[0033] The high-concentration straw biogas fermentation device of this example is the same as the first embodiment except that no connecting pipe is installed.

Embodiment 3

[0035] The high-concentration straw biogas fermentation device of this example is the same as the first embodiment except that the liquid storage unit 1 is a liquid storage tank, and the drain pipe 3 and the overflow pipe 8 are connected to the liquid storage tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com