Construction method for vertical prestressed anchor rope friction pile slope-sliding prevention and treatment

A vertical prestressed and prestressed anchor cable technology, applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve the problems of long embedded section of anti-sliding pile, low anti-overturning ability, and excessively large section size, etc. To achieve the effect of reducing the amount of reinforcement, enhancing the tensile capacity, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

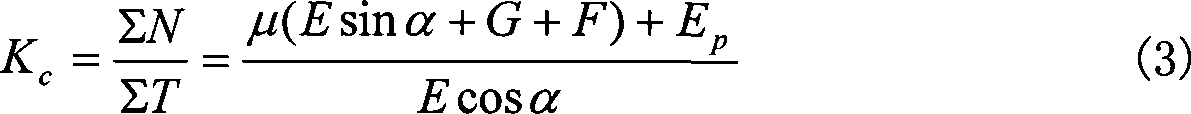

[0036] In Fig. 2, 1, C25 reinforced concrete anchor beam; 2, C25 reinforced concrete anchor head; 3, embedded steel pipe (PVC pipe); 4, prestressed concrete; 5, sliding surface; 6, rock-soil interface; 7, M30 cement mortar; 8, 130mm drilling; 9, prestressed anchor cable; A, prestressed anchor section; B, anti-slide pile anchor section; C, anti-slide pile above the sliding surface.

[0037] Vertical prestressed anchor cable anti-slide pile landslide prevention and control construction method of the present invention, vertical prestressed anchor cable is set in existing anti-slide pile, construction is carried out according to the following steps: a), excavate vertical anti-slide pile on landslide pile holes until deep in the bedrock; b), pre-embed steel pipes or PVC pipes in the pile holes; c), drill the prestressed anchor holes from the bottom of the pile holes (i.e. drill holes); Set the prestressed anchor cable in the middle, and carry out cement mortar pouring; e), place th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com