Method for reinforcing polyester concrete and polyester concrete member provided with reinforcing material

A technology of polyester concrete and reinforcing materials, which is applied in the processing field of polyester concrete components with reinforcing materials and high-strength polyester concrete, which can solve the requirement that the strength is difficult to meet, and limit the application of resin concrete and its products range and other issues, to achieve the effect of reducing the amount of reinforcement, light weight and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

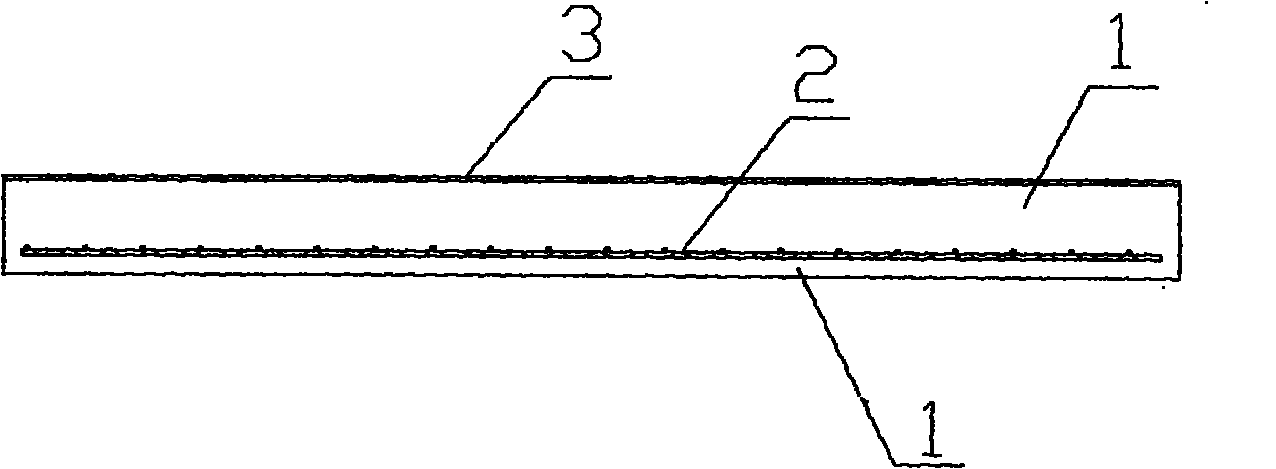

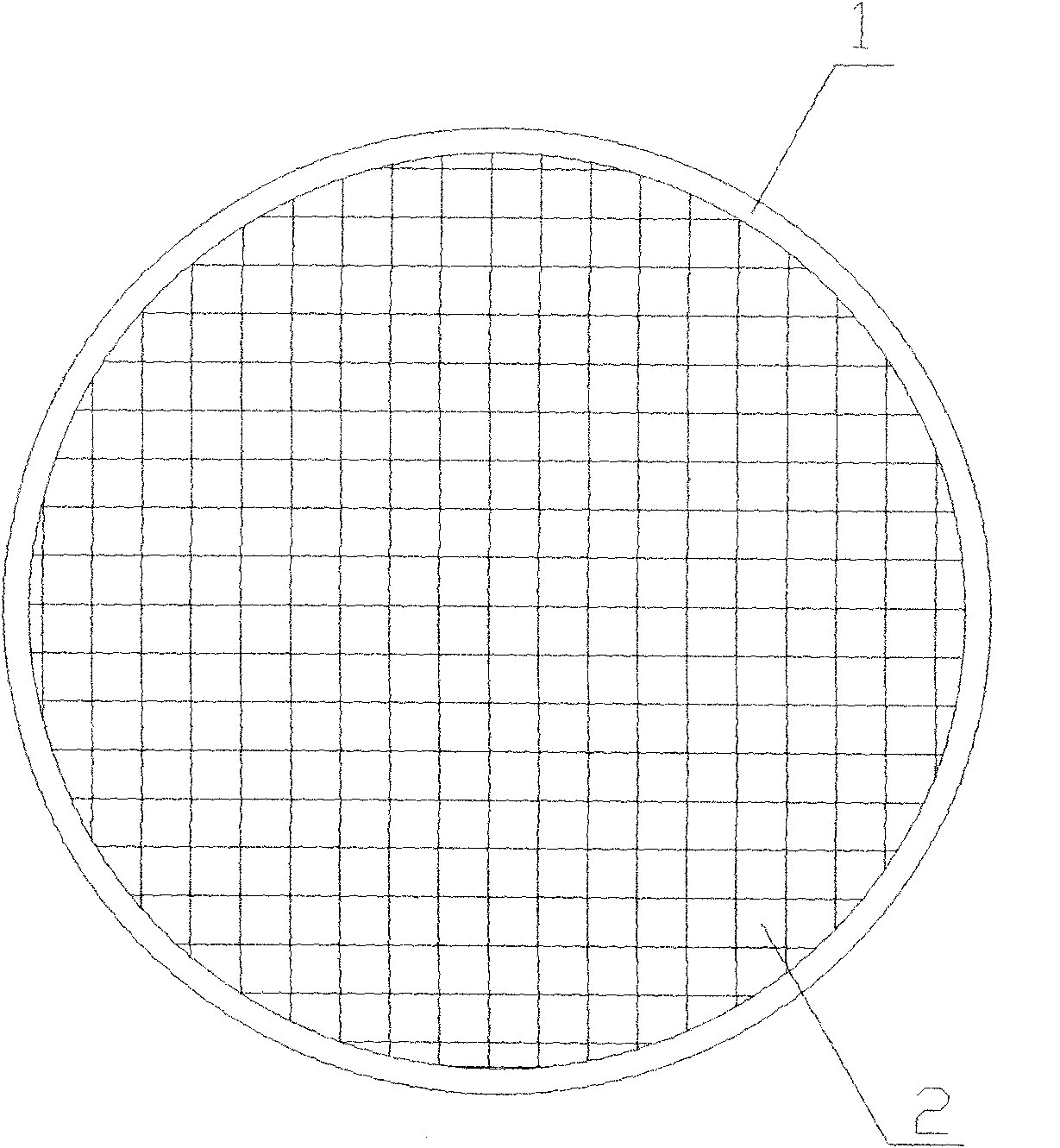

[0031] Such as figure 1 with figure 2 As shown, there is a polyester concrete member with reinforcing materials, and the polyester concrete member is a concrete member made by the above method. The polyester concrete member is set as a flat plate structure, and the inside of the concrete member is laid with reinforcement bars 2 made of glass fiber or carbon fiber structural framework, and glass fiber reinforced mesh or carbon fiber reinforced mesh can also be laid.

[0032] The polyester concrete slab structure includes an upper surface layer 3 , a bottom layer of polyester concrete 1 , and high-strength pultruded fiberglass reinforcement bars 2 or carbon fiber reinforcement bars 2 .

Embodiment 2

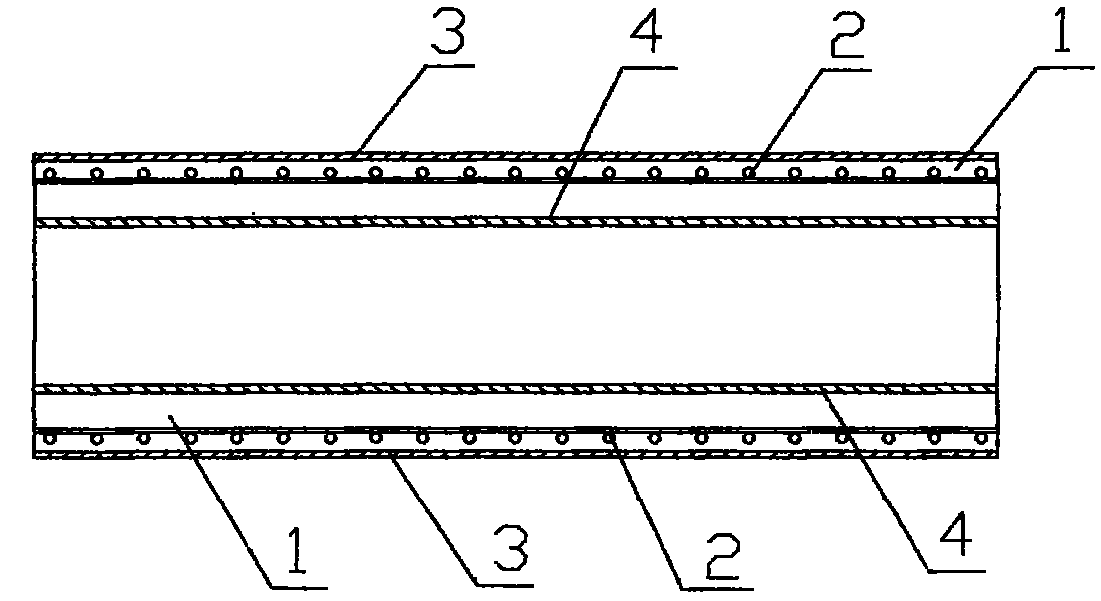

[0034] Such as image 3 with Figure 4 As shown, referring to Embodiment 1, the polyester concrete member is a concrete member made by the above method. The concrete member is set as a tubular structure, including an outer surface layer 3, a middle polyester concrete layer 1, and a high tensile force pultruded glass reinforced plastic reinforcement 2 or carbon fiber reinforcement 2, and the inner surface is set as a smooth coating 4 or a glass fiber mesh. The outer surface layer 3 is set as a colored layer, and the smooth coating layer 4 is made of resin glue, and its smooth surface can reduce the resistance to the fluid, and seal the surface gap to prevent leakage.

Embodiment 3

[0036] Such as Figure 5 As shown, referring to Embodiment 1 and Embodiment 2, the polyester concrete member is a concrete member made by the above method. The concrete member is set as an I-shaped structure, including a polyester concrete layer 1 and a high-tensile force pultruded glass reinforced plastic reinforcing bar 2 .

[0037] The present invention is not limited to the above embodiments, and the concrete member can also be configured as a cuboid or cube structure. The reinforcing bars 2 formed by the glass fiber or carbon fiber structural framework can be arranged inside or on the surface of the concrete member, or both inside and on the surface, or can be laid in combination with the glass fiber reinforced net or the carbon fiber reinforced net to further increase the aggregate strength. Strength of grease concrete members.

[0038] The invention can be applied to bridge decks, anti-corrosion road surfaces, anti-corrosion and pressure-resistant pipelines, anti-foul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com