Surge shaft construction method combining impedance with overflow

A construction method and technology for surge wells, applied in the field of surge wells, can solve the problems of high penetration rate of water hammer waves, reduced effect of reflected water hammer waves in surge wells, complex structure, etc., and achieve simple structure and excellent unit operation Stable and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

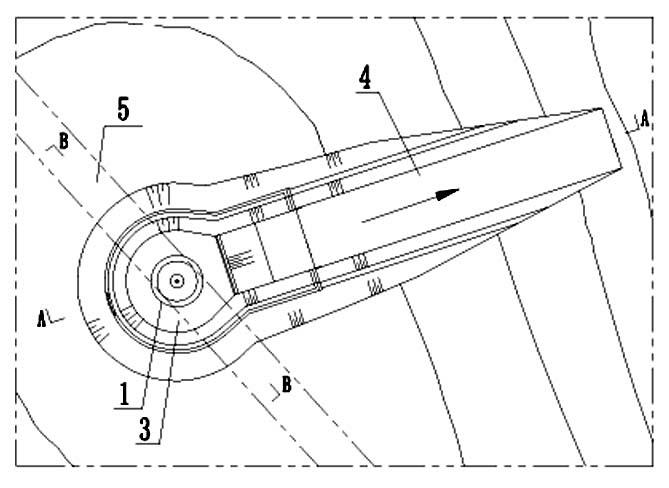

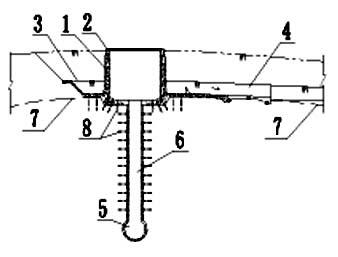

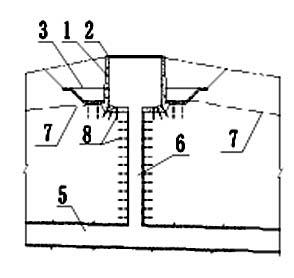

[0024] Such as figure 1 , figure 2 , image 3 As shown, the construction method of the surge shaft combined with impedance and overflow shown in the present invention includes a surge shaft shaft 1, an overflow weir 2 at the top of the surge shaft, a stilling pool 3 around the surge shaft shaft 1, and a drainage channel 4 , The construction of the connecting pipe 6 that plays an impedance role between the wellbore 1 of the surge well and the water diversion power generation tunnel 5;

[0025] 1. Construction of the surge well: The height of the surge well shaft 1 is determined according to the water level of the reservoir, preferably higher than the check flood level. The inner diameter D of the well shaft 1 is determined according to the stable cross-sectional area of the surge well calculated by the Thomas criterion. The well shaft 1 adopts Reinforced concrete structure, the thickness of the shaft wall is based on meeting the requirements of concrete crack resistance an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com