Method for laying rigid long piles and rigid short piles in deep foundation pit support engineering in thick-sludge soft soil area

A technology of silt soft soil and deep foundation pit, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of high enclosure cost and long construction period, and can reduce the amount of concrete and the amount of reinforcement in the pile body. The effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

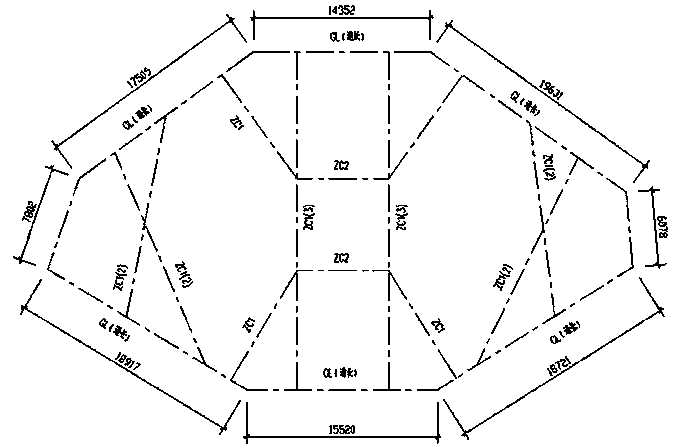

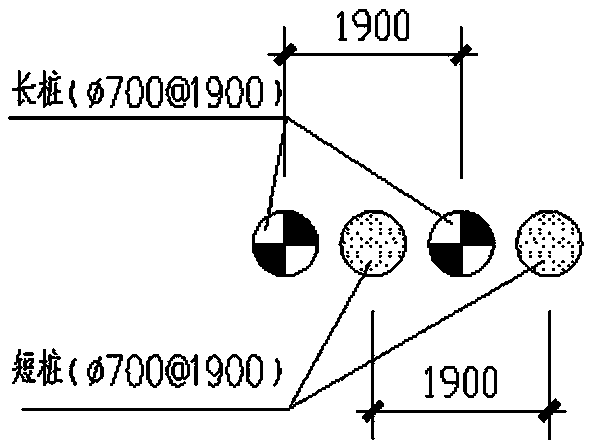

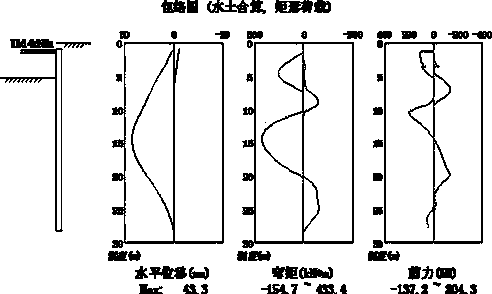

[0011] The laying method of rigid long and short piles in the deep foundation pit enclosure engineering in the deep silty soft soil area provided by the present invention includes A. collecting the building and structure construction drawings of the service objects of the enclosure engineering, specifying the building elevation of the excavation surface, and sorting out the enclosure The floor plan of the project; B. Collect the geological report of the project site, fully understand the field description records of the soil layer within the influence range of the excavation depth of the foundation pit, and the various physical and mechanical test indicators of the soil layer; C. Use deep foundation pit calculation and analysis The software performs routine calculation and analysis on each enclosure section, determines the pile diameter, pile length and pile body reinforcement of the enclosure pile, and uses the design method of alternating long and short piles to review the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com