Novel controlled frame structural system with self-resetting energy dissipating brace

A technology of energy-consuming support and frame structure, which is applied in the direction of building components, building types, building structures, etc., can solve the difficult repair of plastic hinge areas, increase the time of building structure use functions, and increase the repair cost of structural plastic hinge areas to increase building structures Indirect economic loss and other issues to achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

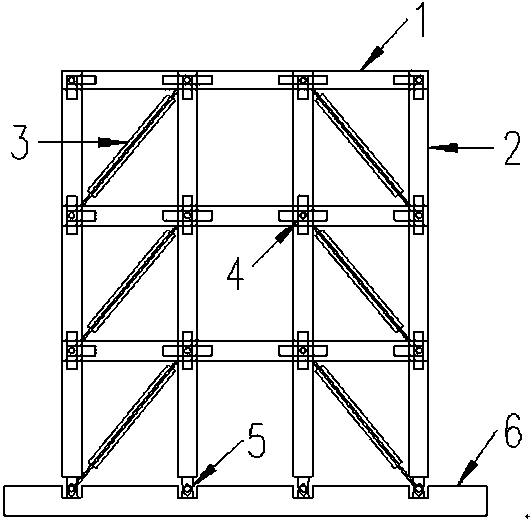

[0018] Embodiment 1: As shown in the figure, the present invention is a new type of controlled frame structure system with self-resetting energy-dissipating supports, which is mainly composed of frame beams 1, frame columns 2, self-resetting energy-dissipating supports 3, and controlled beam-column joints. 4. The controlled column foot node 5 and the foundation 6 are composed. The self-reset energy-consuming support 3 is installed at the inner diagonal position of the side frame of each layer, and the frame beam 1 and the frame column 2 are connected through the controlled beam-column node 4 . The frame column 2 and the foundation 6 are connected through the controlled column foot node 5 .

[0019] The frame beam 1 is a reinforced concrete beam.

[0020] The frame column 2 is a reinforced concrete column.

[0021] The self-reset energy dissipation support 3 is a self-reset anti-buckling energy dissipation support.

[0022] The controlled beam-column node 4 is a hinged node ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com