Steel pipe reactive powder concrete column-flat beam-shear wall structure system

A technology for steel pipe concrete columns and reinforced concrete beams, which is applied in the field of steel pipe reactive powder concrete column-flat beam-shear wall structure system and building structure system, can solve problems that have not been considered, and achieve material cost reduction, cost saving, The effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

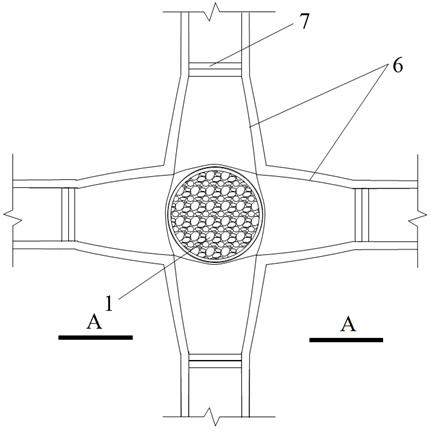

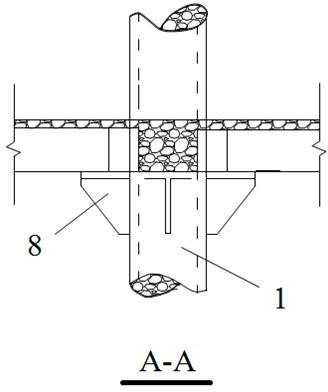

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

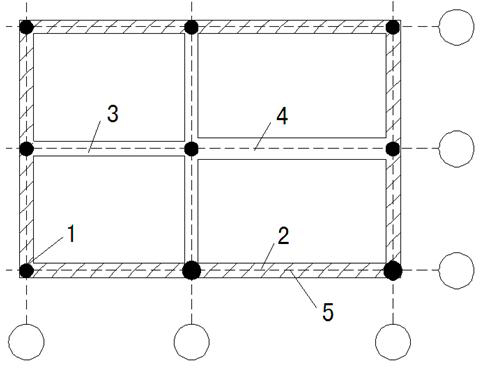

[0029] The steel pipe reactive powder concrete column-flat beam-shear wall structural system of the present invention comprises a steel pipe concrete column, a reinforced concrete beam and a reinforced concrete shear wall 5, and is characterized in that: the steel pipe concrete column is cast by using active powder concrete The steel tube reactive powder concrete column 1, the reinforced concrete beam is a flat beam 2, 3 or 4, that is, the width of the reinforced concrete beam is greater than or equal to the height of the beam.

[0030] In this example, the weight ratio of each component of active powder concrete per cubic meter is: cement: silica fume: sand: ground quartz powder: superplasticizer: steel fiber: water=1:0.23:1.1:0.39: 0.019:0.175:0.19. The sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com