Fabricated light-weight energy consumption wall component of shear wall

A shear wall and prefabricated technology, which is applied in the direction of building components, walls, and building structures, can solve the problem of high pressure in the design of the connection nodes of the inner wall components of the prefabricated shear wall, high pressure in wall transportation, and cracking and damage of the wall and other issues to achieve the effect of improving hoisting efficiency and safety, reducing transportation pressure, and reducing earthquake response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

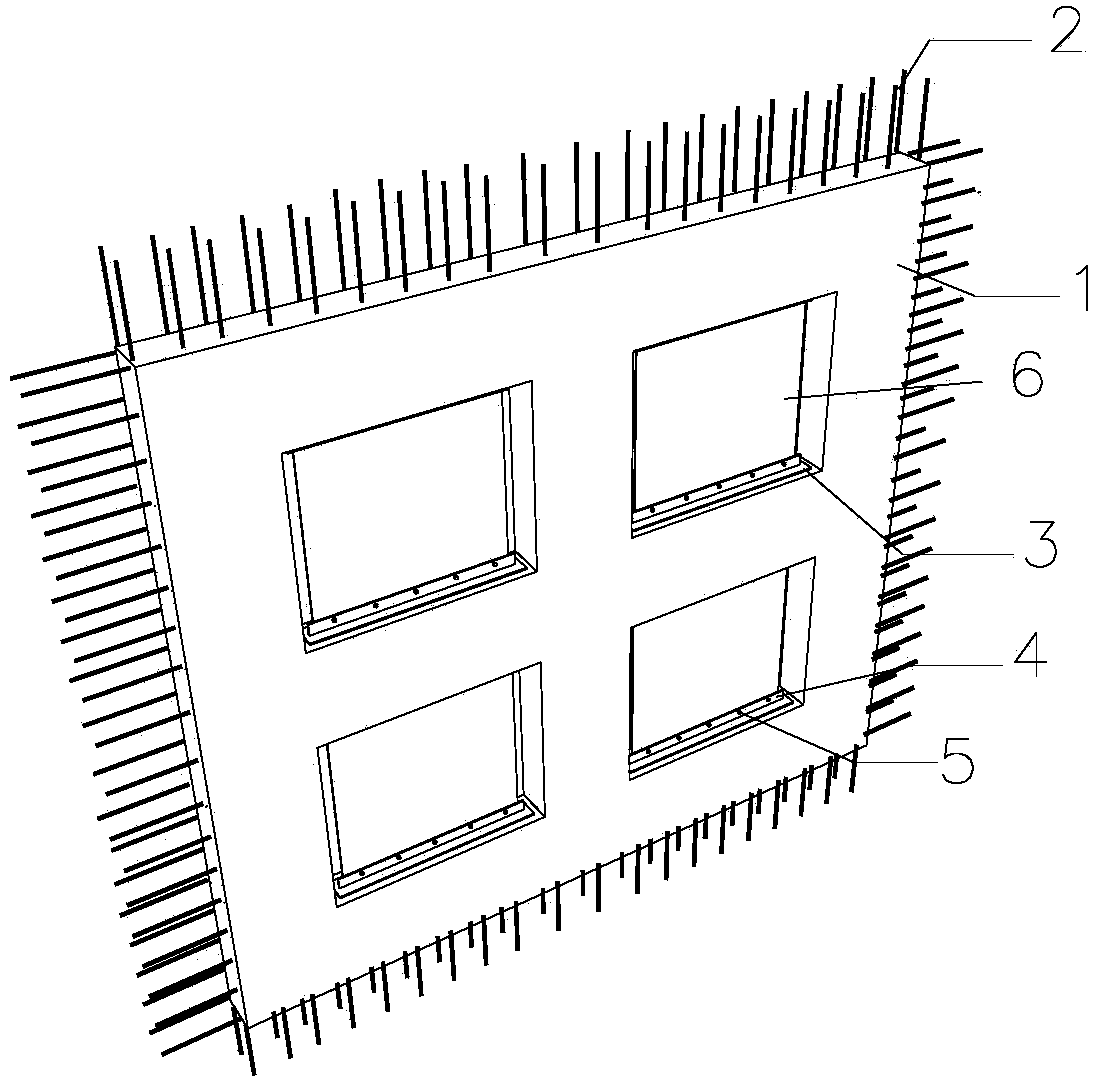

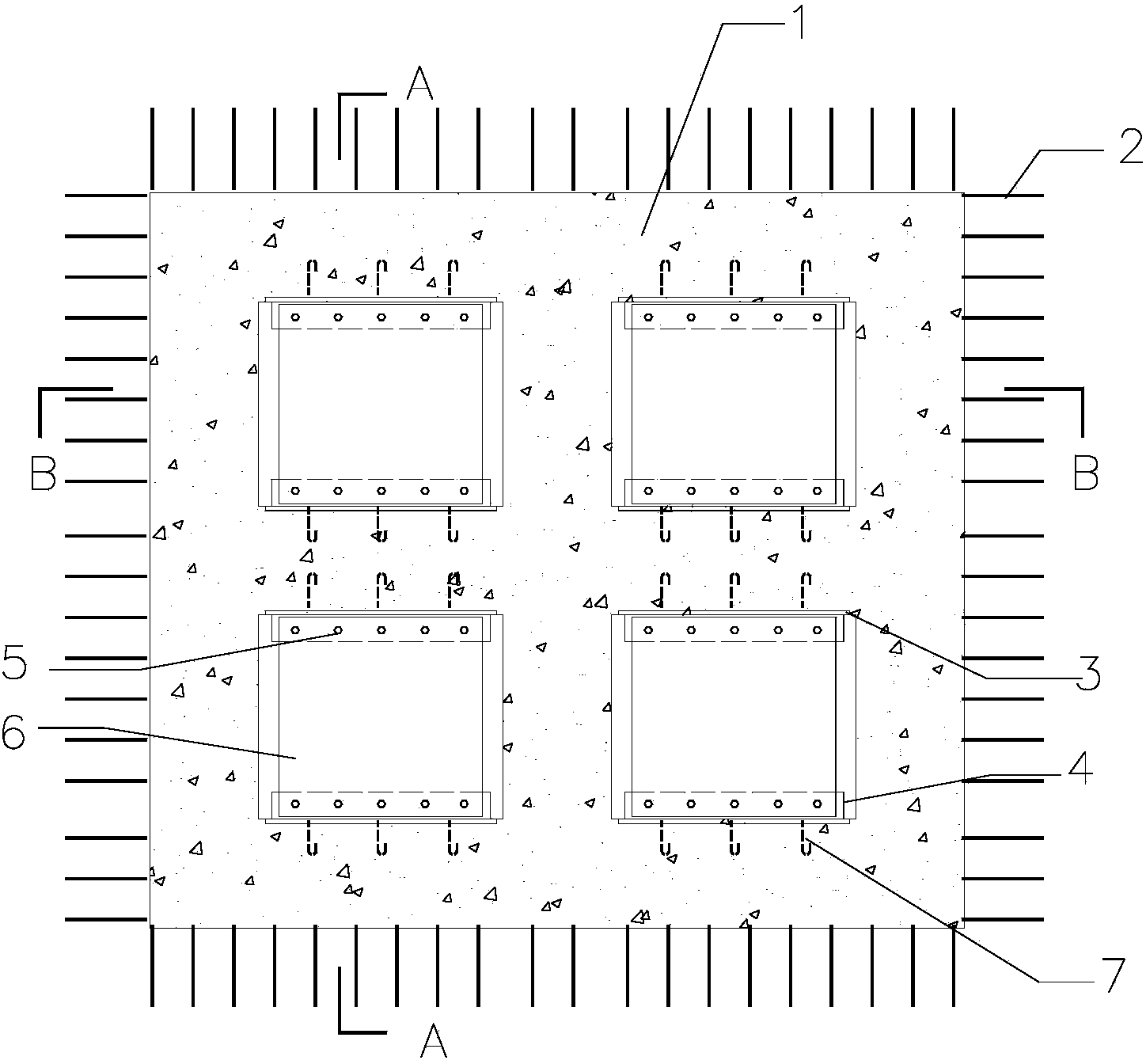

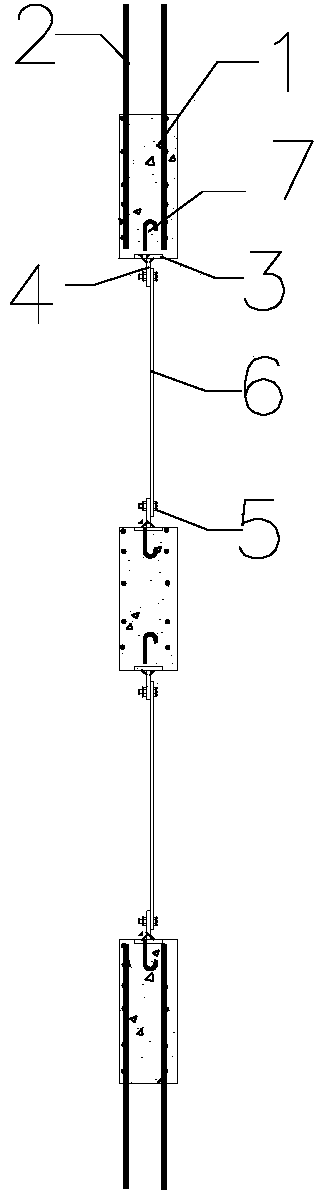

[0024] see Figure 1 to Figure 8 , a light-weight energy-dissipating wall member of a prefabricated shear wall, comprising a reinforced concrete wall panel 1 with reinforcing bars 2 protruding from the edge, and the reinforcing bars 2 of the reinforced concrete wall panel protruding out of the periphery of the wall panel, The reinforced concrete wall panel 1 is provided with a hole, and an energy-dissipating component is fixed on the hole, and the energy-dissipating component includes two hole pre-buried plates 3 and two connecting plates 4 respectively arranged on the top of the hole and the bottom of the hole and yield energy-dissipating steel plate 6, the outer side of the embedded hole plate 3 is welded with the anchor bolt 7, and the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com