Non-uniform reinforcing bar prefabricated support pile as well as forming method and forming die thereof

A forming method and technology for supporting piles, which can be used in molds, sheet pile walls, buildings, etc., can solve the problems of polluting the environment, the inability to prestress the steel cage, and the failure to fully exert the effect of steel reinforcement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

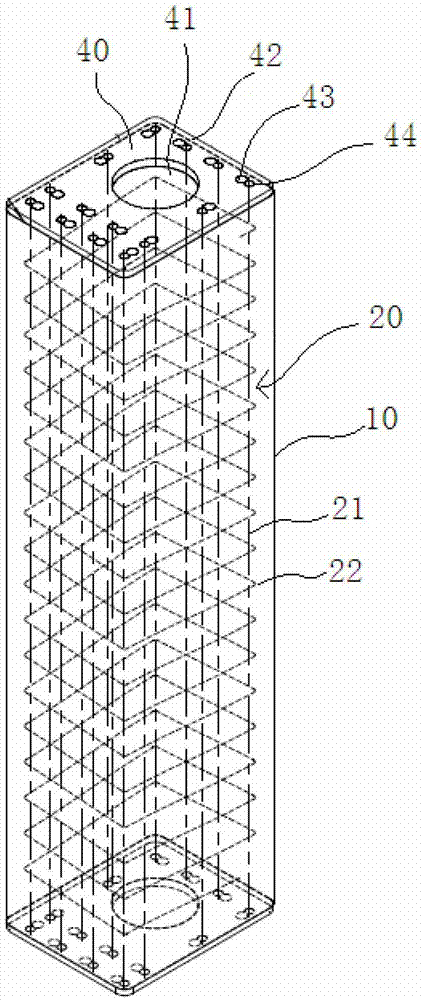

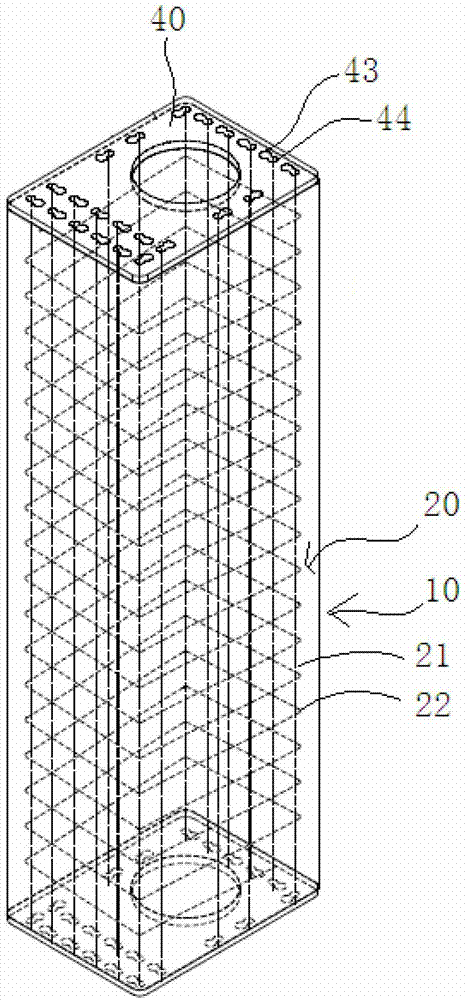

[0119] The structure of the prefabricated support pile with uneven reinforcement in this embodiment is basically the same as the structure of the prefabricated support pile with uneven reinforcement in Embodiment 1, except that the number of main steel reinforcement in the reinforcement cage 20 is different.

Embodiment 3

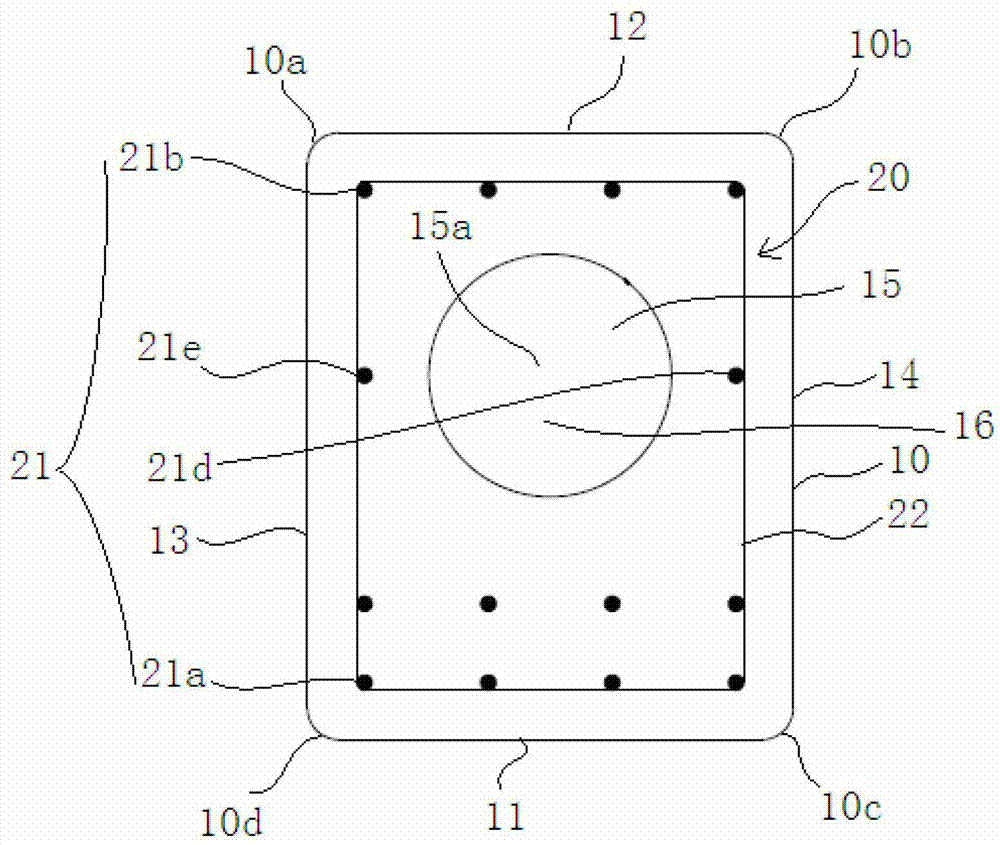

[0121] The difference between the unevenly reinforced prefabricated support pile structure of this embodiment and the unevenly reinforced prefabricated support pile structure of Embodiment 1 is that the cross section of the concrete pile body 10 is a square, and the center 15a of the pile body through hole 15 is not in the same direction as the other. The center of the evenly reinforced prefabricated support pile, that is, the center 16 of the concrete pile body 10 is concentric. The wall thickness of prefabricated support piles with uneven reinforcement is equal. The rest of the structure is the same as the unevenly reinforced prefabricated support pile in Embodiment 1.

Embodiment 4

[0123] see Figure 6 to Figure 8 , the figure shows the mold for forming the unevenly reinforced prefabricated support pile of building foundation pit in Example 1. The wheel 100 and the unevenly reinforced prefabricated support pile forming cylinder 200 arranged in the annular running wheel 100, the inner cavity of the unevenly reinforced prefabricated support pile forming cylinder 200 is the shape of the unevenly reinforced prefabricated support pile Cavity, the center of the inner cavity of the unevenly reinforced prefabricated support pile forming cylinder 200 deviates from the center of the annular running wheel 100, and a certain weight is arranged on the unevenly reinforced prefabricated support pile forming cylinder 200 The weight 300 makes the formed pile body through hole deviate from the center of the pile body, forming the effect that the wall thickness of the pile body varies. The diameters of all annular running wheels 100 are equal.

[0124] The shape of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com