Hinging joint structure of large-span prestressed concrete framed girder

A frame beam and prestressing technology, which is applied in the direction of building construction and construction, can solve the problems of reducing the amount of reinforcement and large bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

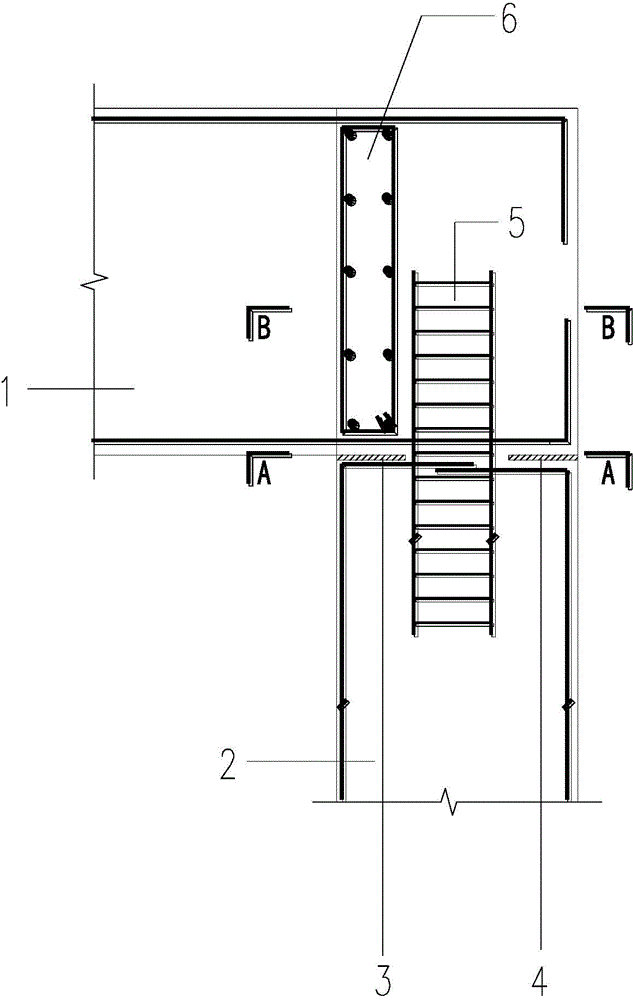

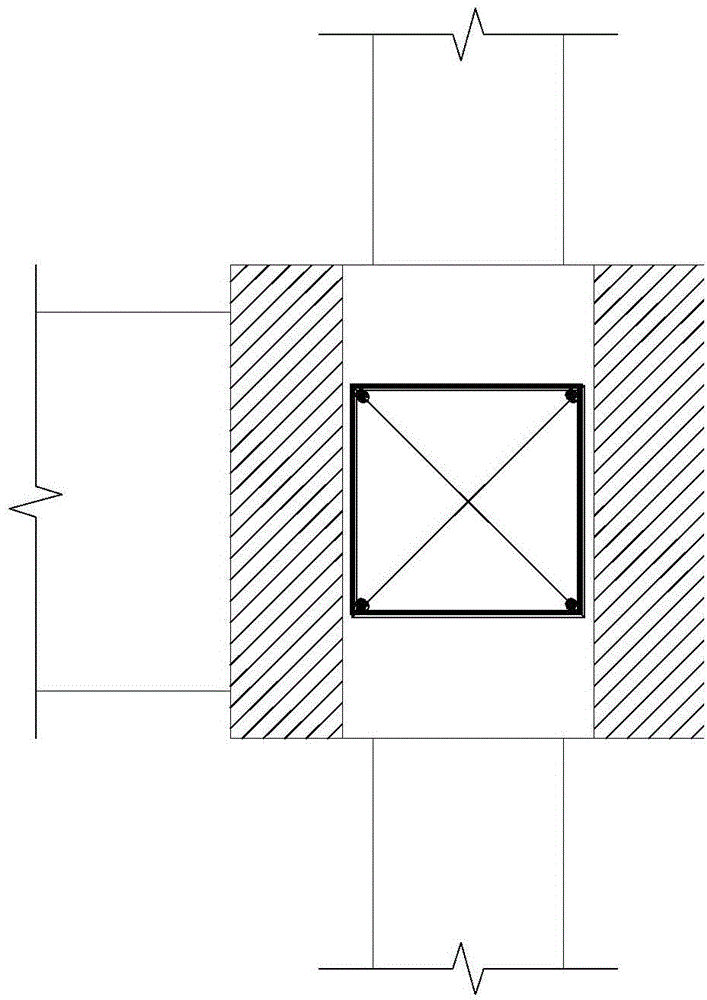

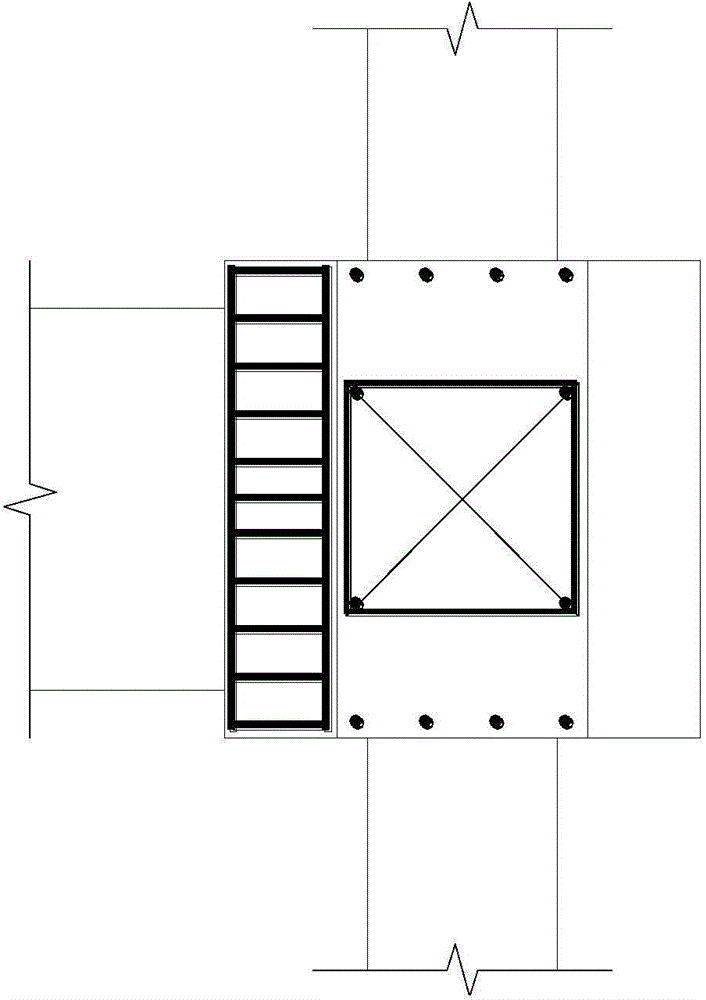

[0017] as attached Figures 1 to 3 As shown, a large-span prestressed concrete frame beam hinge joint structure includes frame beam 1 and frame column 2, and frame beam 1 and frame column 2 are connected together to form a prestressed concrete frame structure, wherein the frame beam 1 The inner side and outer side of the interface between the bottom surface and the top surface of the frame column 2 are respectively provided with an inner isolation layer 3 and an outer isolation layer 4, and the inner isolation layer 3 and the outer isolation layer 4 are made of tetrafluoro board, and the width of the tetrafluoro board is the frame column. 1 / 4 of the height, the length is the same as the width of the frame column, and the thickness is 5mm. The inner side and outer side main bars of the frame column 2 are bent and anchored at the beam bottom elevation. The frame beam 1 and the frame column 2 are connected by a reinforced concrete core column 5, the reinforced concrete core colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com