Environmental-friendly water-based antirust agent

A water-based anti-rust agent, an environmentally friendly technology, applied in the direction of anti-corrosion coatings, etc., can solve the problems of acid-base sensitivity, affect the appearance, and pollute the working environment, and achieve the effect of stabilizing the pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

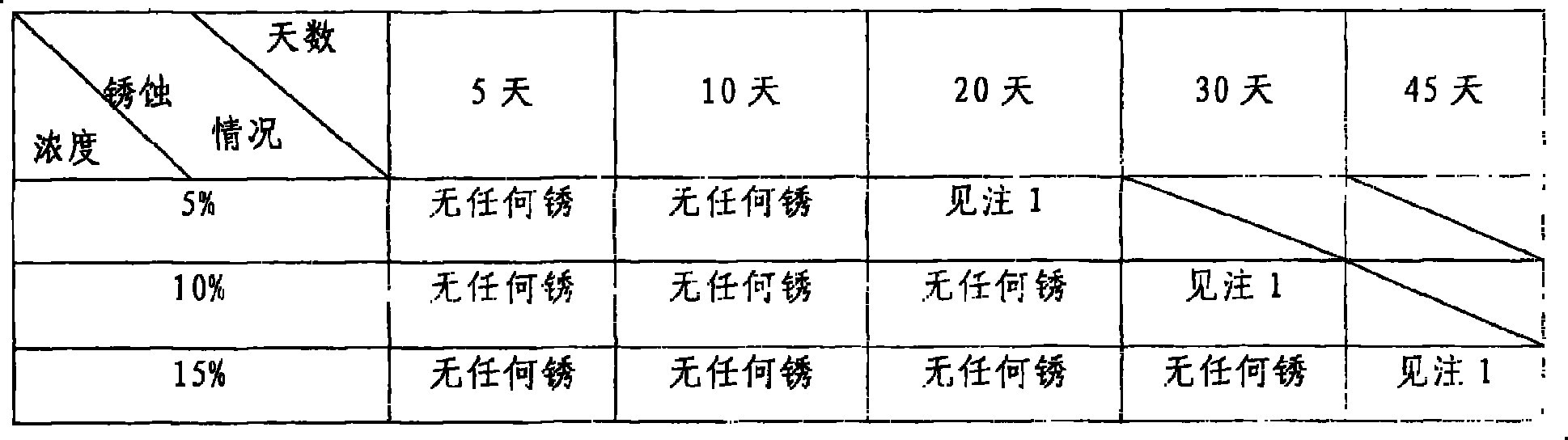

Examples

Embodiment 1

[0021] Example 1: Add 48.0 parts of tap water to a three-necked flask with a stirrer, a thermometer, and a condenser tube, start the stirrer and add 17.9 parts of boric acid, 16.3 parts of diethanolamine, and 10.0 parts of monoethanolamine in sequence, and heat over low heat until the solution is colorless and uniform liquid. Then heat it up to the solution boiling, condense and reflux for 40min. Then add 0.69 parts of sodium hydroxide to the three-necked flask, and reflux for 30 minutes. Stop heating, and when the solution is cooled to 80°C, add 3.5 parts of 5-chlorobenzotriazole and 3.6 parts of oleic acid amide into the three-necked flask, and stir evenly.

Embodiment 2

[0022] Example 2: Add 60.0 parts of tap water to a three-necked flask with a stirrer, a thermometer and a condenser, start the stirrer and add 15.9 parts of boric acid and 16.3 parts of triethanolamine in turn, and heat over low heat until the solution is a colorless and uniform liquid. Then heat it up to the solution boiling, condense and reflux for 40min. Then, 1.3 parts of ammonia water and 0.4 parts of sodium hydroxide were added into the three-necked flask, and condensed and refluxed for 30 minutes. Stop heating, and when the solution is cooled to 80°C, add 3.2 parts of benzotriazole, 1.6 parts of sodium petroleum sulfonate, and 1.3 parts of oleic acid amide into the three-necked flask, and stir evenly.

Embodiment 3

[0023] Example 3: Add 57.0 parts of tap water to a three-necked flask with a stirrer, a thermometer and a condenser tube, start the stirrer and add 18.9 parts of boric acid and 18.3 parts of monoethanolamine in turn, and heat over low heat until the solution is a colorless and uniform liquid. Then heat it up to the solution boiling, condense and reflux for 40min. Stop heating, and when the solution is cooled to 80°C, add 4.0 parts of urotropine and 1.8 parts of oleic acid amide into the three-necked flask, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com