Waterborne rust conversion primer coating with rust and preparation method thereof

A rust-to-rust and primer technology, applied in the field of coatings, can solve the problems of rapid drying limitation, easy rust return, environmental pollution, etc., and achieve the effects of easy operation, good adhesion and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

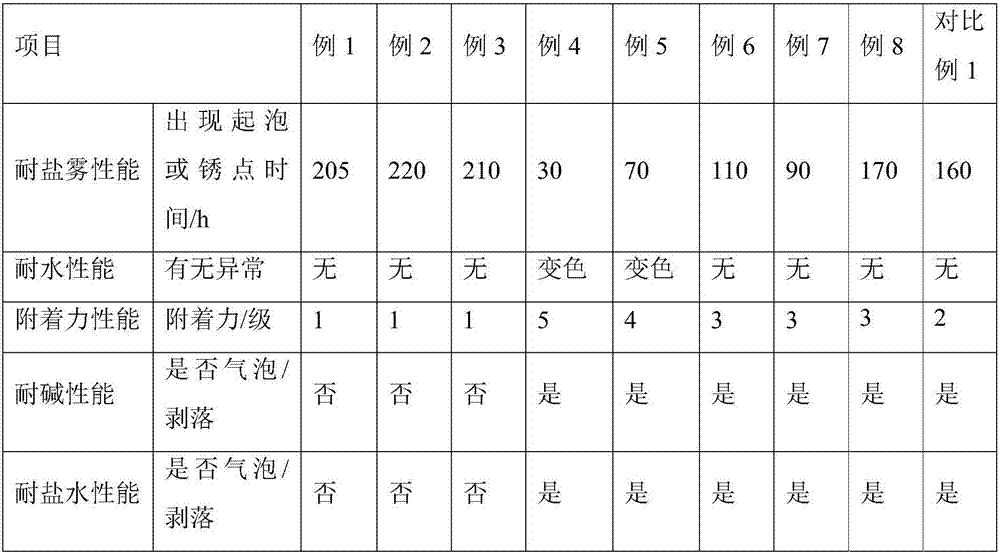

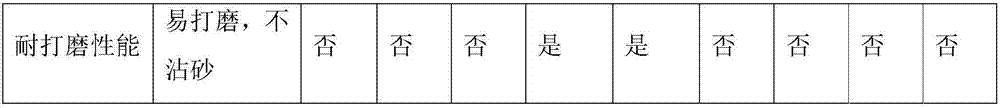

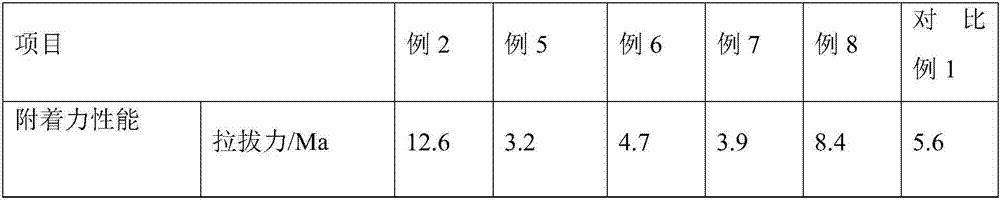

Examples

preparation example Construction

[0030] A kind of preparation method of water-based band rust turning rust primer coating, it comprises steps:

[0031] S100 Stir and disperse the corresponding weight parts of corrosion inhibitor, stabilizer, thickener, wetting and dispersing agent, defoamer, bactericide and deionized water under the condition of 800-1000r / min for 5-30min to obtain a mixed solution;

[0032] S200 Stir and disperse the corresponding weight parts of the rust-transforming agent, rust-transforming aid, film-forming aid and water-based epoxy anti-rust emulsion under the condition of 500-1500r / min for 5-20min, and add the mixed solution in step S100 therein, Continue to stir for 5-20min under the condition of 500-1500r / min to obtain A component;

[0033] For S300, mix component A and component B evenly at a ratio of 2 to 3:1, and age for 10-30 minutes to obtain a water-based rust-converting rust primer, which is ready for use.

[0034] Wherein, the rust reducing agent in the step S200 is ionic liqu...

Embodiment 1

[0045] The preparation method of water-based rust turning rust primer paint is as follows:

[0046] (1) 5 parts by weight of stabilizer, 0.5 part by weight of corrosion inhibitor, 0.1 part of thickener, 0.3 part by weight of wetting and dispersing agent, 0.2 part by weight of defoamer, 0.05 part by weight of bactericide and 15 parts by weight of deionized water in Stir and disperse at 800r / min for 30min to obtain a mixed solution;

[0047] (2) Stir and disperse 2 parts by weight of rust converting agent, 2 parts by weight of rust converting aid, 2 parts by weight of film forming aid and 30 parts by weight of water-based epoxy antirust emulsion at 500r / min for 20min, and add the step For the mixed solution in (1), continue to stir for 20 minutes under the condition of 500r / min to obtain A component;

[0048] (3) Mix component A and component B evenly according to the ratio of 2:1, and after aging for 30 minutes, obtain a water-based rust-converting rust primer coating, which i...

Embodiment 2

[0056] The preparation method of water-based rust turning rust primer coating is as follows:

[0057] (1) 6 parts by weight of stabilizer, 3 parts by weight of corrosion inhibitor, 0.3 parts by weight of thickener, 0.6 parts by weight of wetting and dispersing agent, 0.5 parts by weight of defoamer, 0.2 parts by weight of bactericide and 25 parts by weight of deionized water in Stir and disperse for 10 minutes under the condition of 1000r / min to obtain the mixed solution;

[0058] (2) Stir and disperse 5 parts by weight of rust converting agent, 3 parts by weight of rust converting aid, 4 parts of film forming aid and 50 parts by weight of water-based epoxy antirust emulsion at 1500r / min for 10min, and add step For the mixed solution in (1), continue stirring at 1500r / min for 10min to obtain component A;

[0059] (3) Mix component A and component B evenly according to the ratio of 2:1, and after aging for 30 minutes, obtain a water-based rust-converting rust primer coating, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com