Ceramic-based composite material capable of defensing 12.7mm armor piercing incendiary

A technology of composite materials and incendiary bombs, applied in the field of ceramic materials, can solve the problems of high brittleness, poor resistance to multiple bullets, low bending strength and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 A kind of ceramic matrix composite material that can defend against 12.7mm armor-piercing incendiary bombs

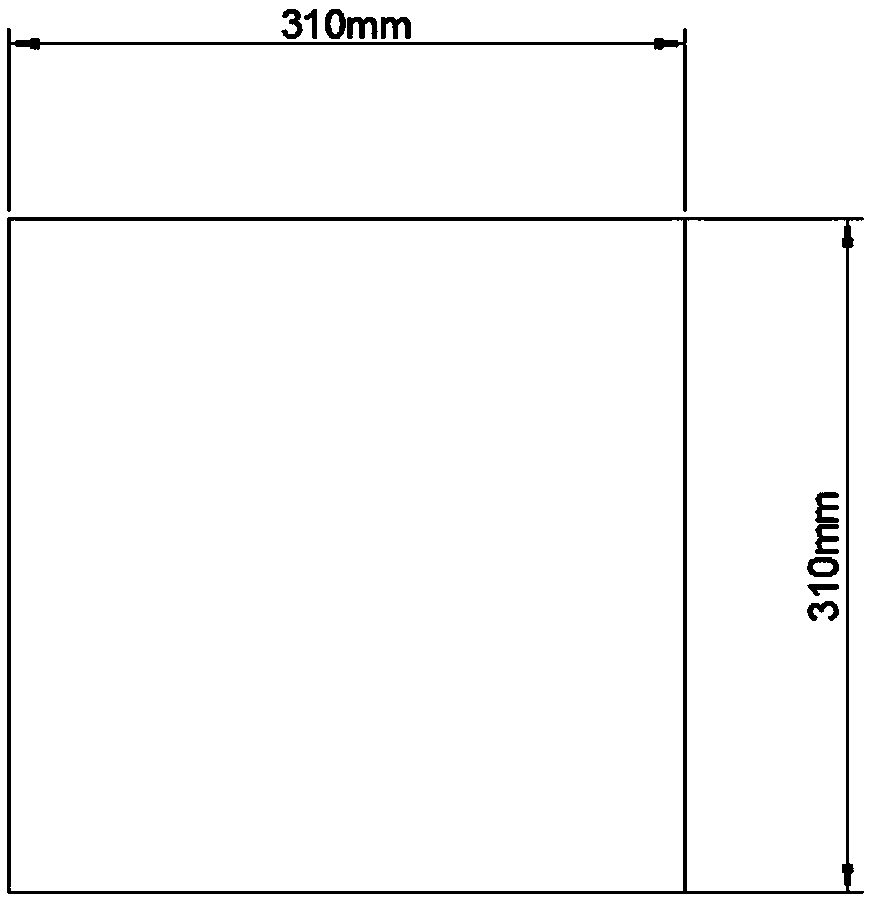

[0022] Such as figure 1 As shown, the ceramic matrix composite material capable of defending against 12.7mm armor-piercing incendiary bombs is a square with a side length of 310±2mm and a thickness of 35mm.

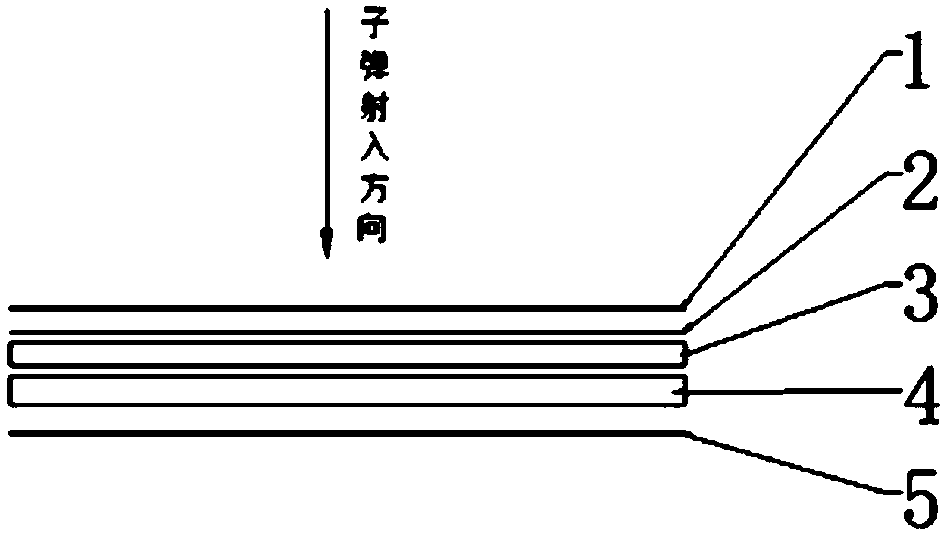

[0023] Such as figure 2 As shown, a ceramic matrix composite material that can defend against 12.7mm armor-piercing incendiary bombs, the material includes a polyurea layer, an aramid fiber layer 2, a ceramic layer 3 and a PE layer 4, and the aramid fiber layer, ceramic layer and PE layer Arranged in sequence from top to bottom and bonded together by an adhesive to form an intermediate layer, the upper and lower surfaces of the intermediate layer are spray-coated with polyurea layers 1,5; wherein, the thickness of the polyurea layers 1,5 is 0.5mm, the aramid layer is 1mm, the ceramic layer is 15mm, and the PE layer is 18mm; the aramid layer i...

Embodiment 2

[0025] Example 2 A preparation method of a ceramic matrix composite material capable of defending against 12.7mm armor-piercing incendiary bombs

[0026] Such as figure 1 As shown, the external dimension is a square with a side length of 310±2mm and a thickness of 35mm. The material is composed of 5 layers of materials. Among them, the upper surface and the lower surface are sprayed with a 0.5mm thick polyurea layer, which has the advantages of wear resistance, waterproof, anti-rust, anti-mildew, etc.; figure 2 Middle 1, 5 floors;

[0027] A method for preparing a ceramic matrix composite material capable of defending against 12.7mm armor-piercing incendiary bombs, comprising the steps of:

[0028] Step 1) The aramid fiber layer is 1mm, which is combined with 6 layers of woven cloth and epoxy resin adhesive, which acts as a buffer bullet and ceramic crack arrester, such as figure 2 In the 2nd floor.

[0029] Step 2) The ceramic layer is a graphene-toughened boron carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com