Bolt damage-free environment-friendly clearing device

A cleaning device and non-damaging technology, applied in the field of machinery, can solve the problems of cleaning agents containing toxic and harmful substances, easy to rust, and bolt scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

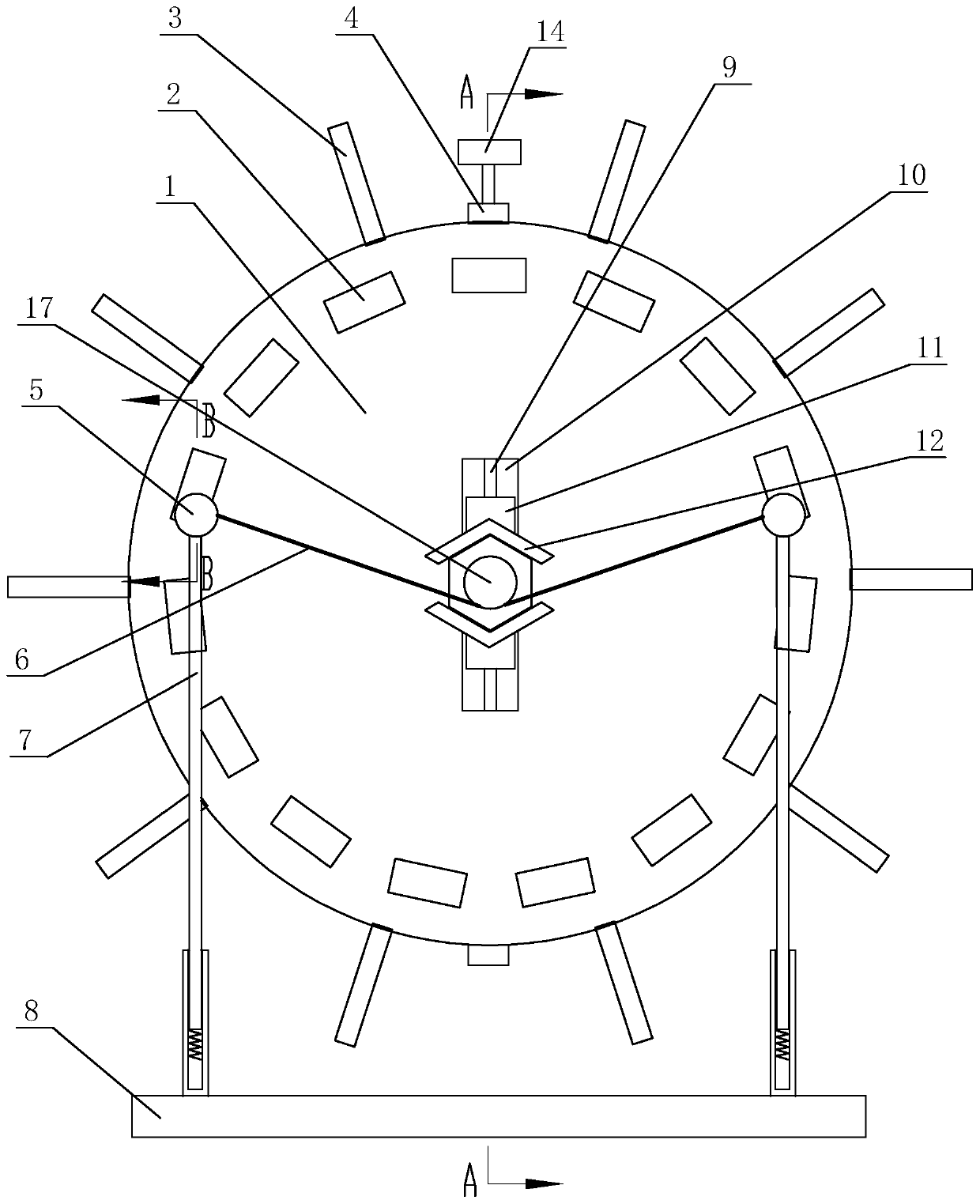

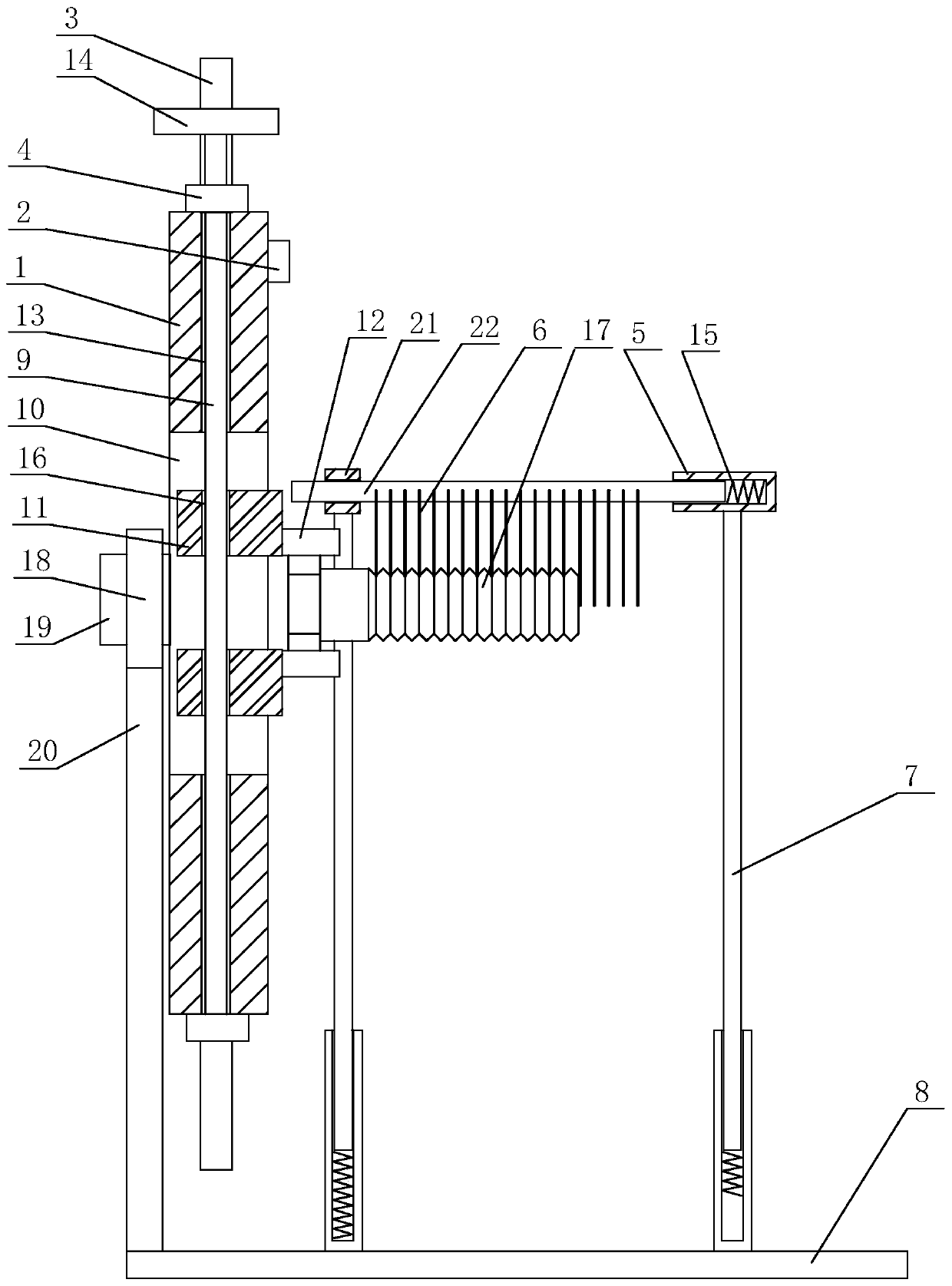

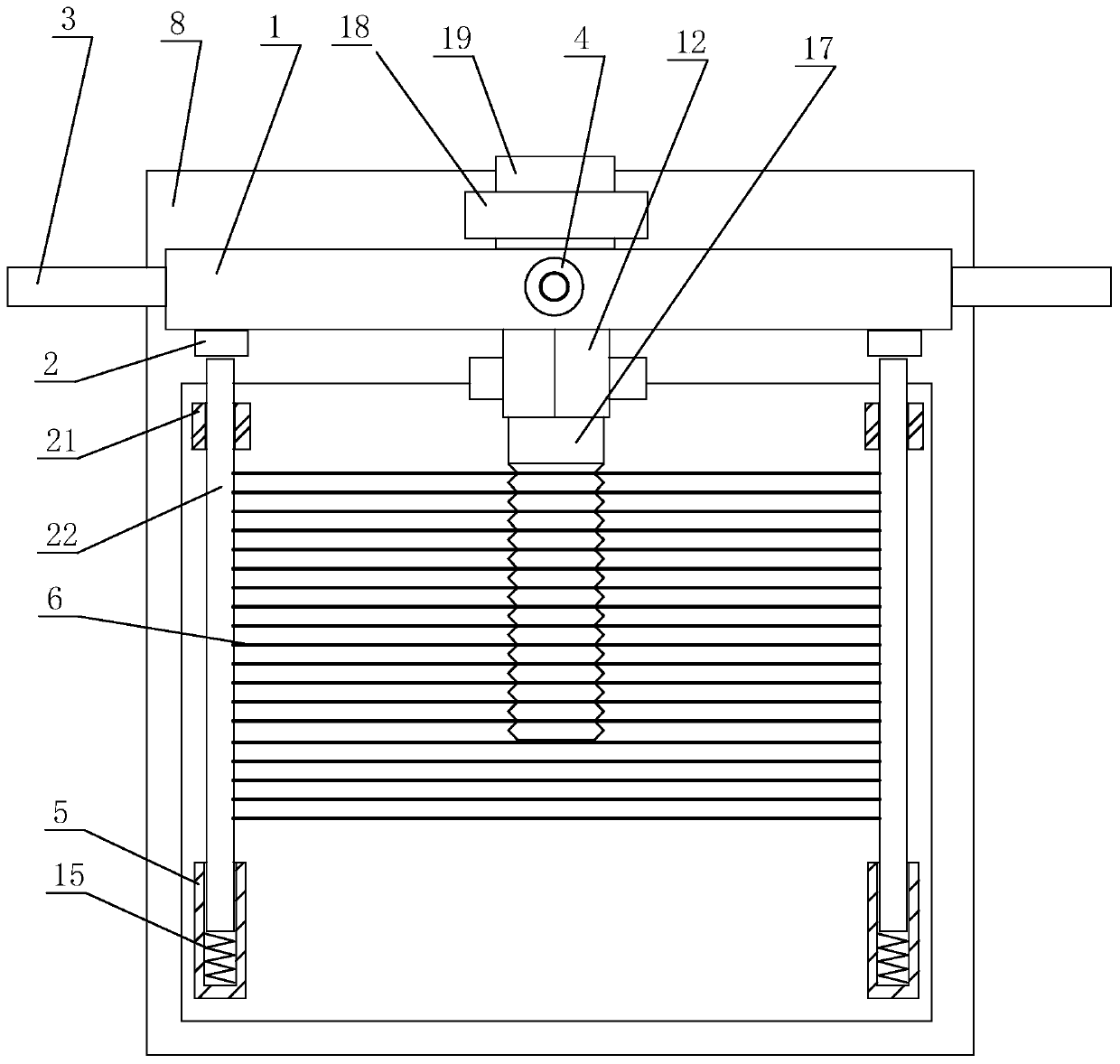

[0024] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0025] Such as Figure 1-Figure 4 As shown, the bolt-free environmental protection cleaning device of the present invention includes a base 8, a vertically fixed column 20 on the base 8, a large bearing 18 fixed on the column 20, a rotating shaft 19 coaxially fixed on the inner ring of the large bearing 18, and the inner end of the rotating shaft 19 The turntable 1 is coaxially fixed, the fixing device is arranged on the turntable 1, and the handle 3 is evenly distributed on the edge of the turntable 1;

[0026] Including a cleaning device, the cleaning device includes two reciprocating rods 22, the front parts of the two reciprocating rods 22 are arranged in the rod sleeve 21, and the rear ends are fitted in the outer cylinder 5, and a spring 15 is arranged in the outer cylinder 5, and one end of the spring 15 is against the reciprocating The rear end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com