Rust-proof sealing structure of add-in motor pump set rotating shaft junction

A shaft connection and motor shaft technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of polluting the environment, rusting and infiltration at the joint of the shaft, and achieves the improvement of operation quality, prevention of rusting of the shaft, and stable products performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

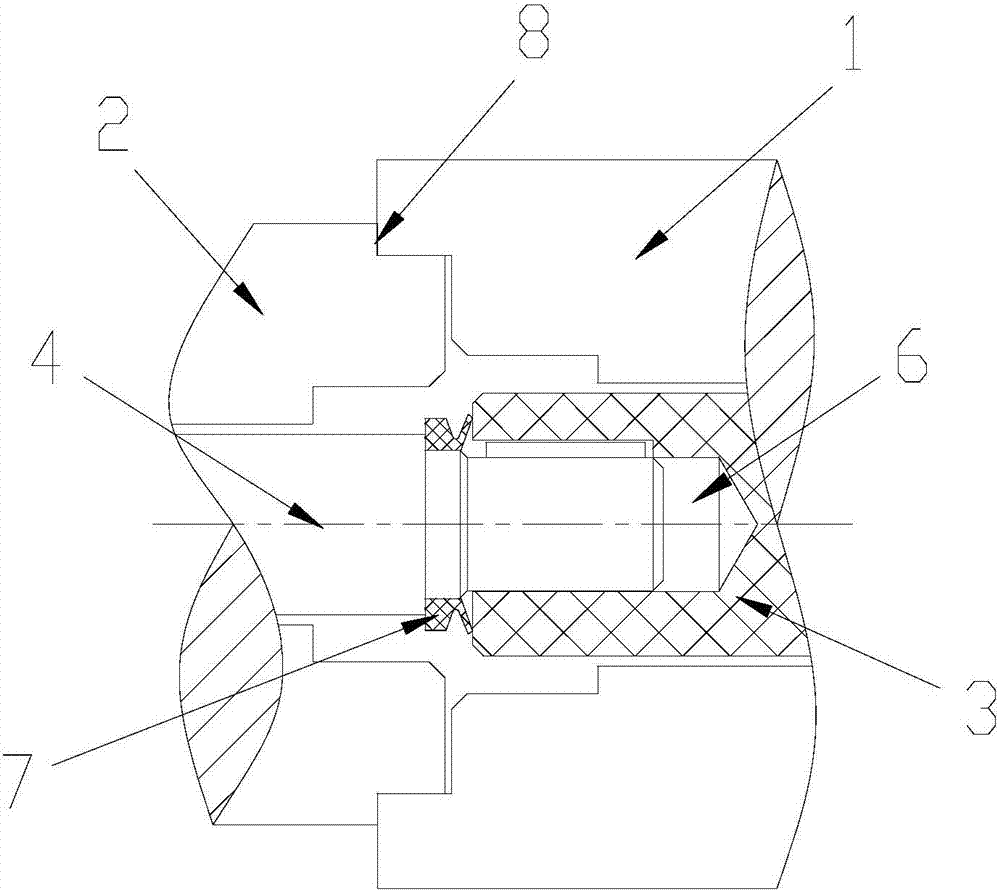

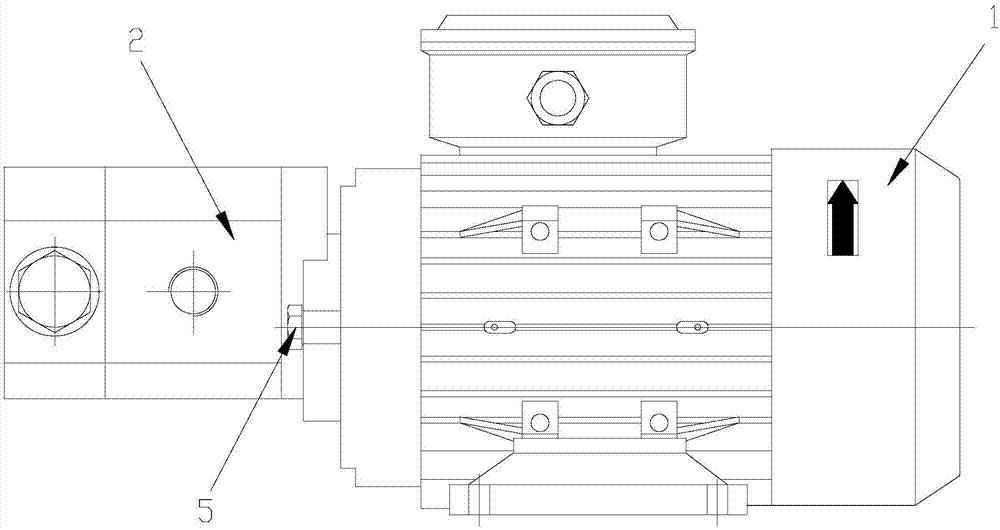

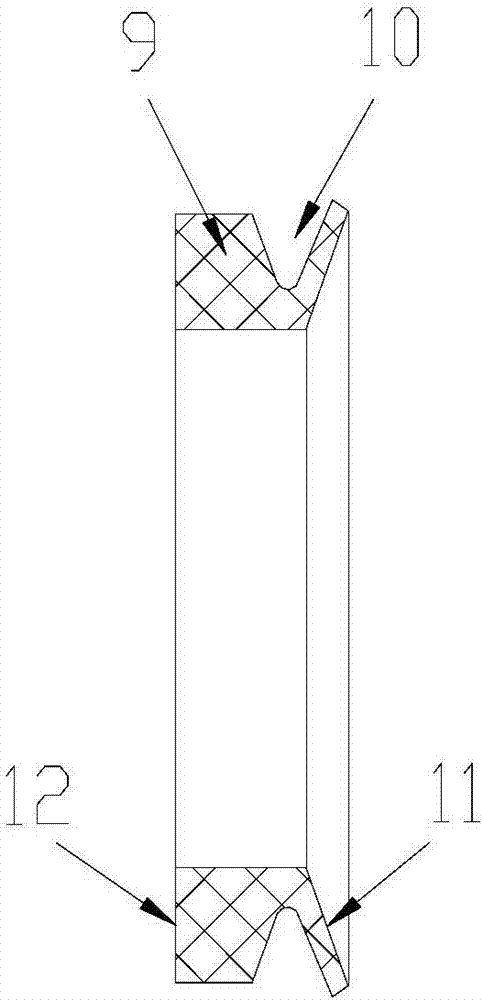

[0029] As shown in the drawings, the present invention includes: motor 1, oil pump 2, motor shaft 3, oil pump shaft 4, motor shaft 3 is provided with an inner hole, oil pump shaft 4 is inserted into the inner hole of motor shaft 3, oil pump shaft 4 and motor A rotating shaft connection chamber 6 is formed between the rotating shafts 3, and the oil pump 2 and the motor 1 are fastened by a locking screw 5. The waterproof level of the motor is generally IP54, and a V-shaped sealing ring 7 is arranged on the rotating shaft of the oil pump, and the V-shaped sealing ring 7 is annular Structure, the section of the V-shaped sealing ring 7 is V-shaped, the V-shaped sealing ring 7 and the oil pump shaft 4 are sealed and connected with interference fit, and the lip of the V-shaped sealing ring 7 forms a contact seal with the front surface of the motor shaft 3 , The front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com