Safe and practical obstacle avoidance device for plant pruning knife rest

A practical and vegetative technology, applied in the field of plant pruning, can solve the problems of reducing the work efficiency of sanitation workers, the tool holder is easy to encounter obstacles, and the sanitation workers are troublesome to operate, etc., so as to increase the pruning range, increase pruning efficiency, and achieve good pruning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

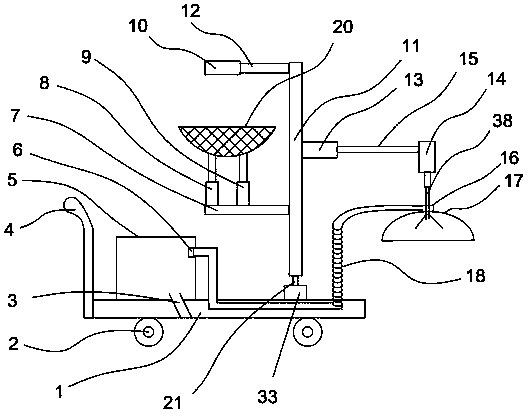

[0020] Such as figure 1 As shown, the safe and practical plant pruning tool holder obstacle avoidance device includes a frame 1, a roller 2 is provided at the lower end of the frame 1, a handle 4 is provided on one side of the upper end of the frame 1, a crushing device is provided above the frame 1, and the crushing device One side is provided with elevating platform 33, and elevating platform 33 is on frame 1 upper end, and elevating platform 33 upper ends are connected fixed plate 11, and fixed plate 11 is provided with guide rail, and guide rail is provided with slide block 13, and one end of slide block 13 passes telescopic rod 15 Connect, telescopic rod one end connects motor 14, and motor 14 output ends are connected with pruning device by rotating telescopic rod 38, guide rail is provided on fixed plate, and guide rail is provided with slide block, and slide block one end is connected by telescopic rod, and telescopic rod one end connects motor , the output end of the ...

Embodiment 2

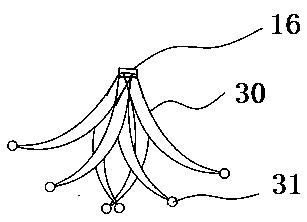

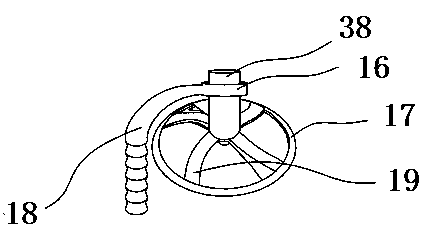

[0023] Such as Figure 1-2As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: trimming device, including a turntable 16, the upper end of the turntable 16 is connected with the rotating telescopic rod 38, and the lower end is connected with the dome shape 17, and the rotating telescopic rod 38 passes through the turntable 16 is connected with the rotary blade 30, the rotary blade 30 and the rotary telescopic rod 38 are hollow structures, the front end of the rotary blade 30 is provided with a rubber ball 31, the rubber ball 31 is provided with air holes, and the rotary telescopic rod is set to pass through the rotating disk to connect with the rotary blade, The rotating blade rotates with the rotating telescopic rod and rotates parallel to the dome shape to form an airflow around the branches and leaves to increase the shearing efficiency. The rotating blade and the rotating telescopic rod are hollow structures. When the vacuum cleaner is worki...

Embodiment 3

[0026] Such as Figure 4 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is as follows: the crushing device includes a storage box 5, a rotating shaft 28 is evenly distributed in the storage box 5, and staggered crushing teeth 29 are uniformly distributed on the rotating shaft 28, and the storage The inner upper end of box 5 is provided with vacuum cleaner 6, and one end of vacuum cleaner 6 is connected with recovery pipeline 18, and the middle section of recovery pipeline 18 is spring-shaped, and the bottom of storage box 5 is provided with discharge port 3, and the branches and leaves after pruning are cleaned by setting vacuum cleaner at the upper end of storage box inner side. For collection and processing, a number of rotating shafts are set in the storage box, and a number of staggered crushing teeth are set on the rotating shaft to crush the collected branches and leaves, and the middle section of the recovery pipe is spring-shaped, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com