Axis driving type optical lens cleaning equipment

A technology for cleaning equipment and optical lenses, which is applied to cleaning flexible objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of long cleaning time and poor cleaning effect, and achieve full cleaning, ingenious and reasonable structural design, and easy cleaning significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

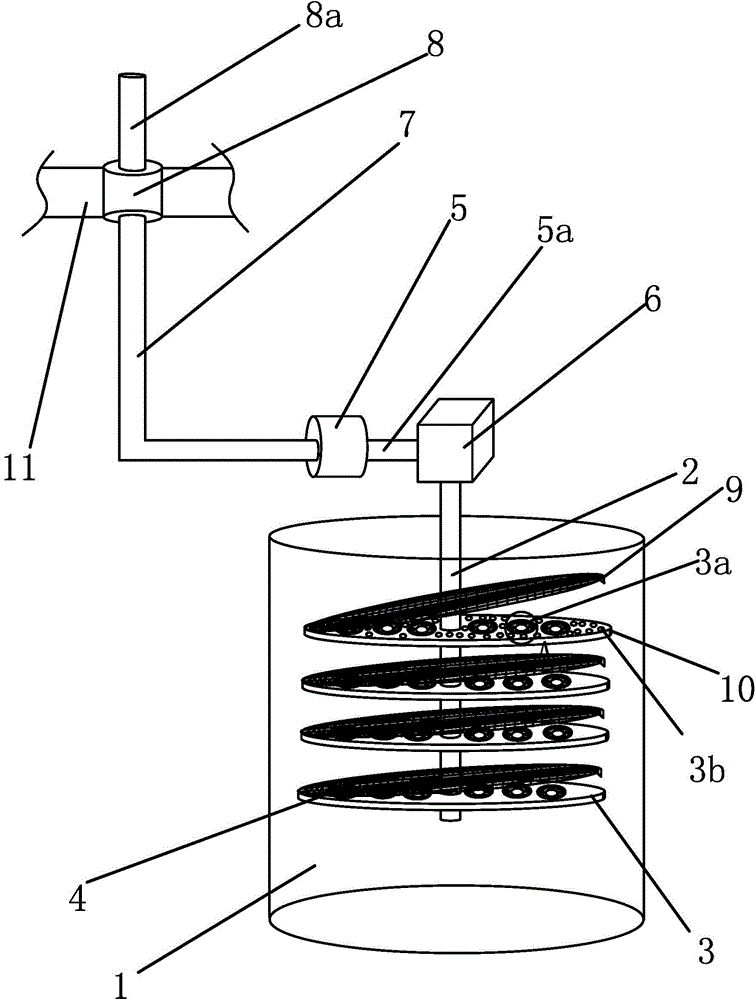

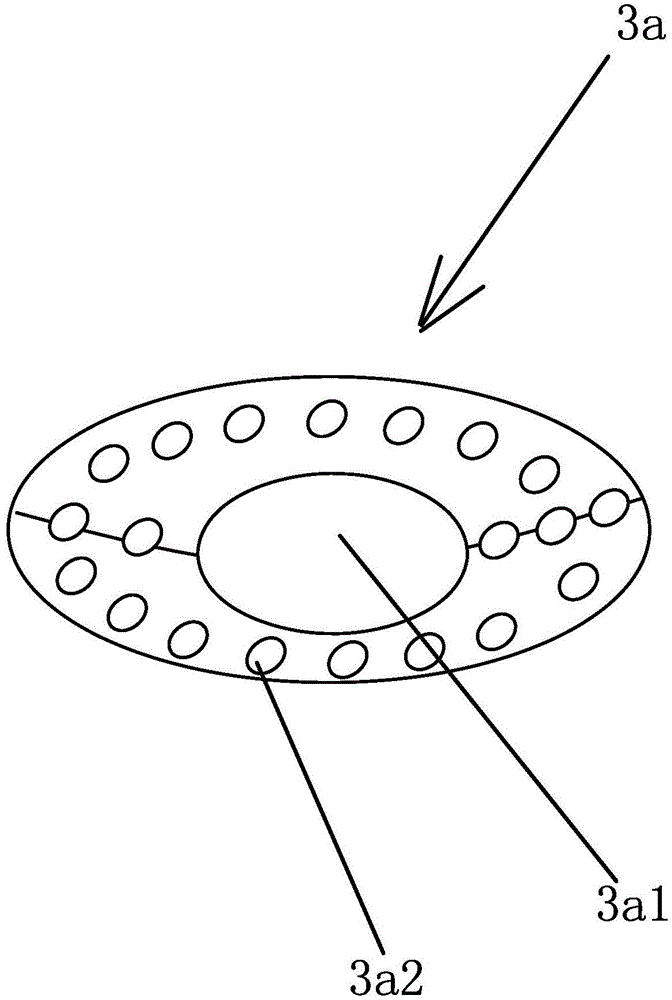

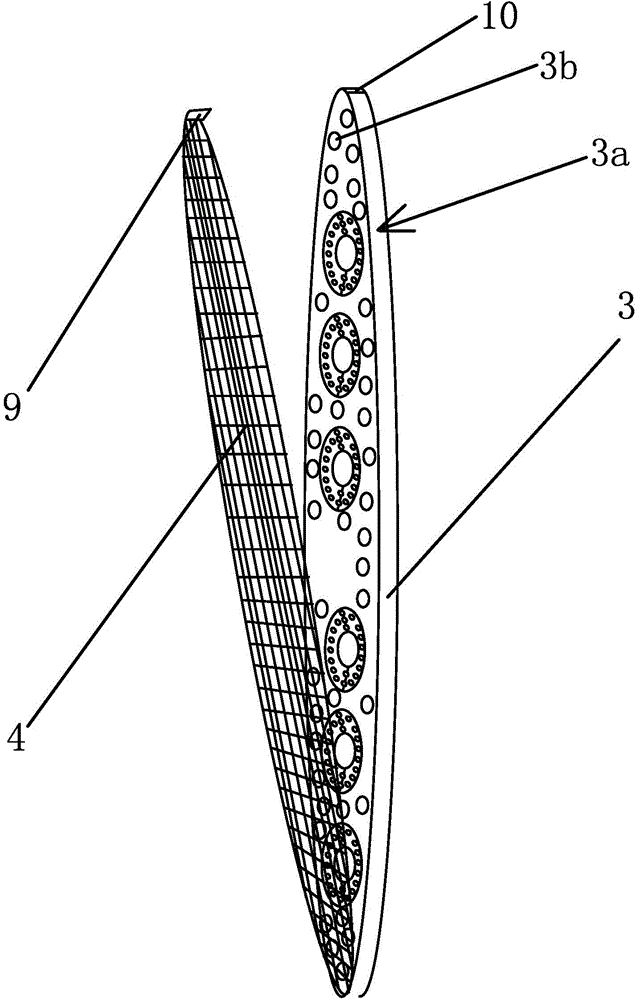

[0026] Such as Figure 1 to Figure 4 As shown, the shaft-moving optical lens cleaning equipment includes a barrel-shaped cleaning bucket 1 with an opening at the upper end. There is a loading mechanism extending from the opening in the cleaning bucket 1. The loading mechanism includes a vertically arranged loading shaft 2 and several A loading plate 3 fixedly connected to the loading shaft 2, the upper side of the loading plate 3 has a plurality of ellipsoidal lens grooves 3a for placing optical lenses, and the lens grooves 3a are in the shape of a neck from top to bottom And the bottom center of the lens groove 3a has the bottom hole 3a1 that runs through the both sides of the loading plate 3, the lens groove 3a has a plurality of water passage holes 3a2 that run through the both sides of the loading plate 3, and the loading plate 3 has multiple holes. Two water holes 3b, each loading plate 3 is hinged with a rubber net 4 made of rubber material, the rubber net 4 is circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com