Patents

Literature

40results about How to "Conform to shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical self-heating far infrared hot compress bag

InactiveCN102846425AAvoid restrictionsAchieve ease of useLight therapyTherapeutic coolingExternal energyCutaneous microcirculation

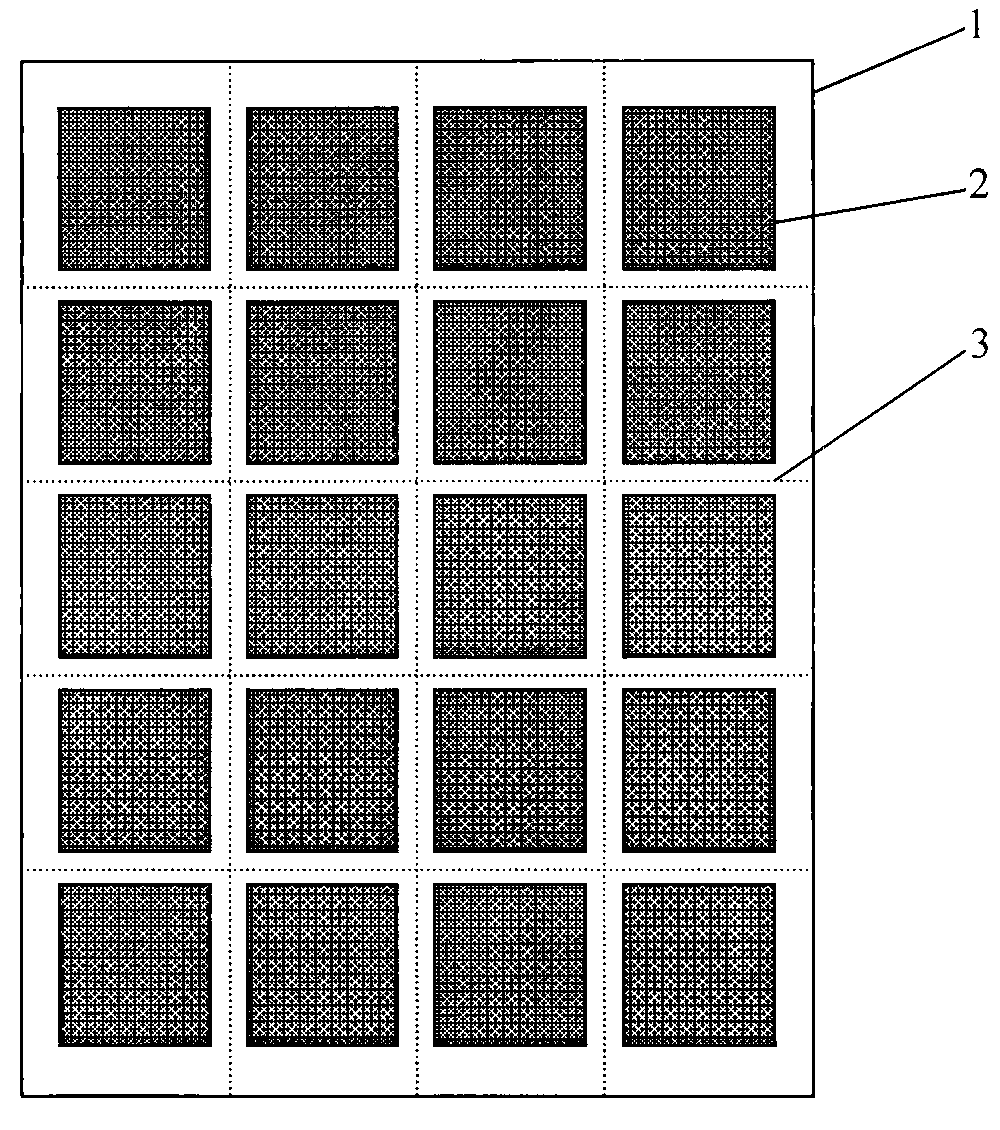

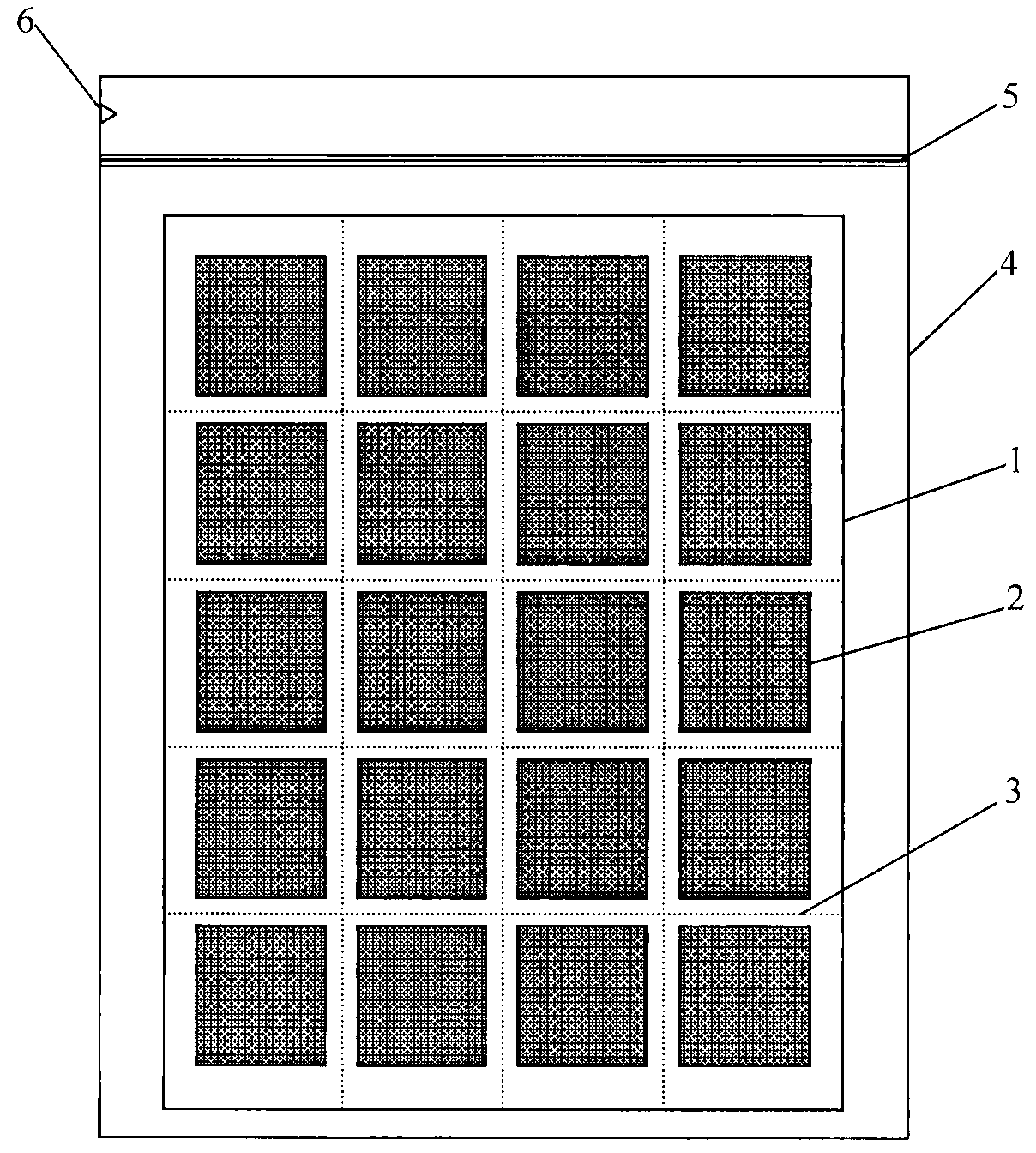

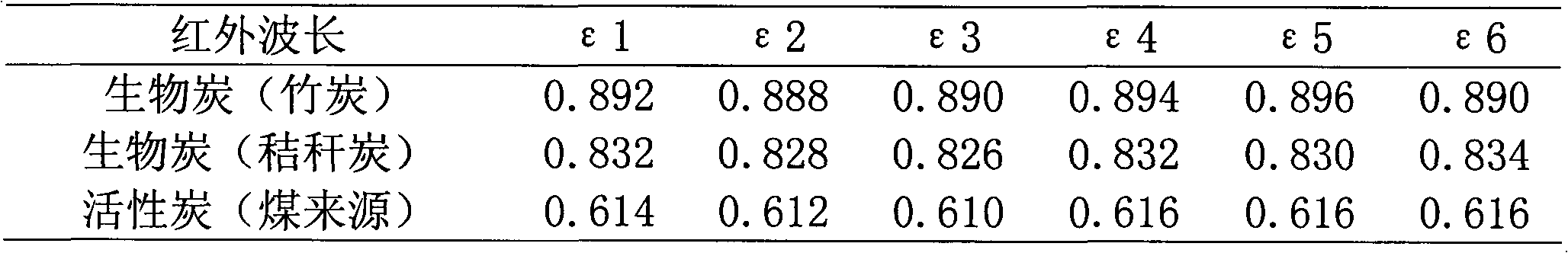

The invention belongs to the field of medical devices, and relates to a medical self-heating far infrared hot compress bag for physiotherapy and health care. A heating agent in the medical self-heating far infrared hot compress bag contains biochar which can efficiently emit suitable far infrared rays. The biochar has appropriate granularity, and can be activated char and inactivated char or a mixture of the activated char and the inactivated char for realizing the balance of heating temperature, time and far infrared ray releasing. The inner bag of the hot compress bag consists of a plurality of small bags which are isolated from each other, perforations are arranged between the small bags for partitioning, and the small bags can be torn off according to the requirements. The outer bag of the hot compress bag can be a vacuumized sealed package and is provided with a self-sealing strip, and the unused part can be put in the outer bag and sealed. The medical self-heating far infrared hot compress bag is low in price, convenient to carry and easy to use, does not need an external energy source, and can satisfy the requirements on treatment at any time, long-term health care and people of remote regions. The biochar can also take the functions of absorbing sweat and odor and regulating skin microcirculation. The inner bag is specially designed to be fit with the shape of an afflicted part and avoids waste, and the usability is further improved through the seal-sealing design and vacuumization of the outer bag.

Owner:袁暾 +1

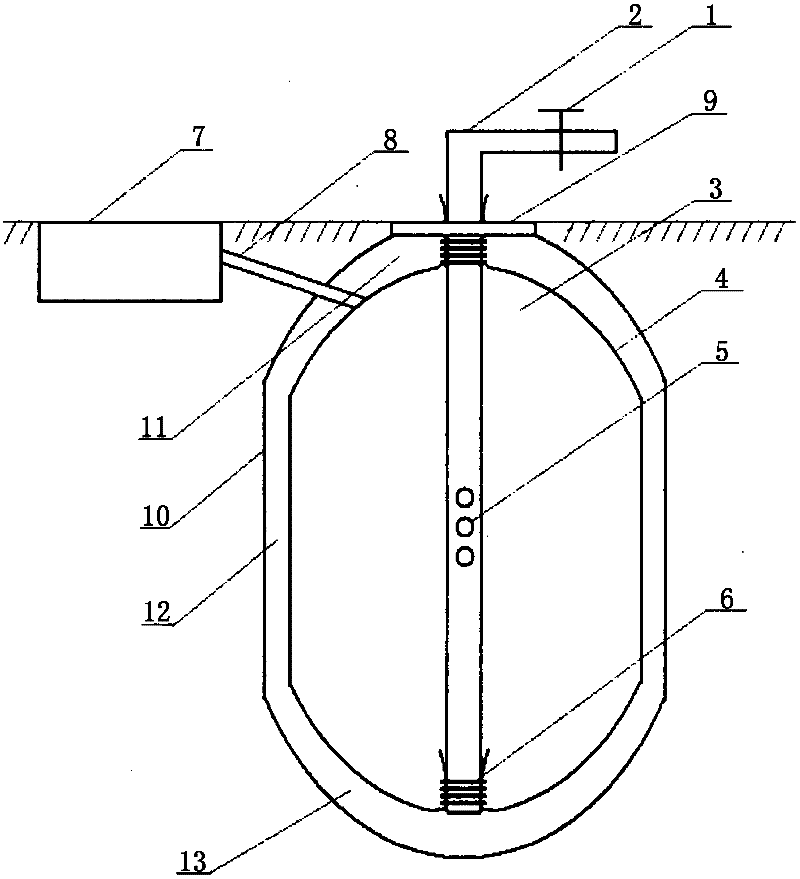

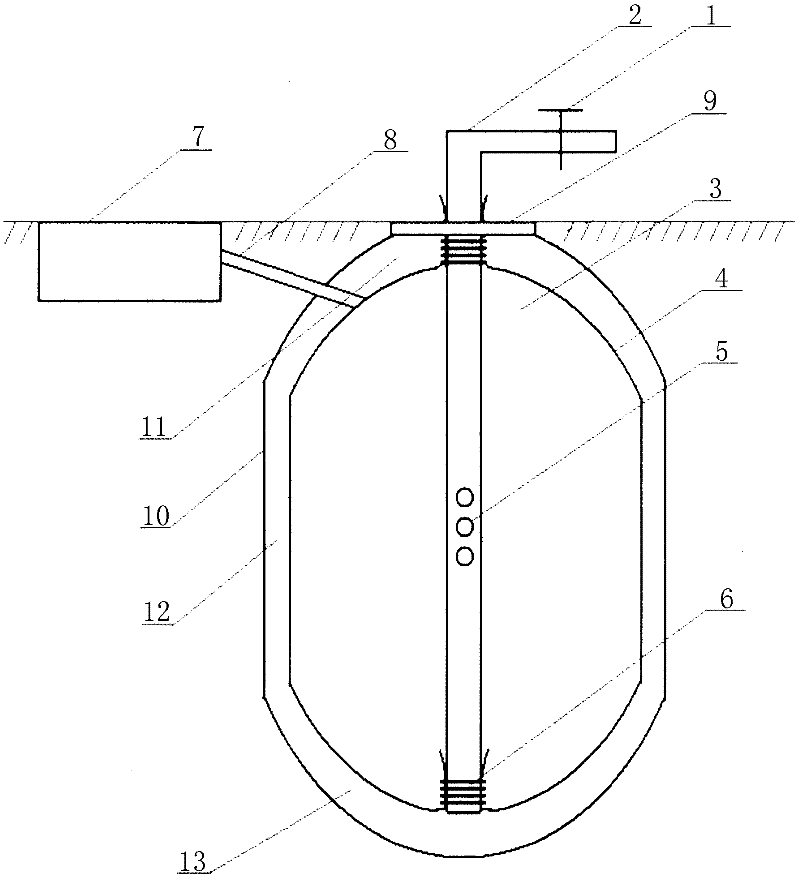

Device and method for quickly constructing small water cellar

The invention discloses a device and a method for quickly constructing a small water cellar. The device disclosed by the invention comprises an inflatable air bag corresponding to the inner wall of the water cellar and a steel pipe for inflating the air bag, wherein the steel pipe is inserted into the air bag and is fixedly connected with an upper port and a lower port of the air bag in a sealing manner. The method for quickly constructing the small water cellar by use of the device comprises the steps of excavating a foundation pit, pouring to form a cellar bottom, putting a constructing device, charging air at 5-6kpa to the device, pouring to form cellar walls and a cellar top, sucking air in the device and taking out the device; using cement mortar, waterproof mortar and cement to treat fine aggregate concrete inner walls; and finally, mounting a cellar cover. The device and the method for quickly constructing the small water cellar have the characteristics of the structure is simple, the use is convenient, the labor can be saved, the cost is reduced, and the construction period is shortened. In addition, the constructed water cellar is firm and durable.

Owner:庄文贤

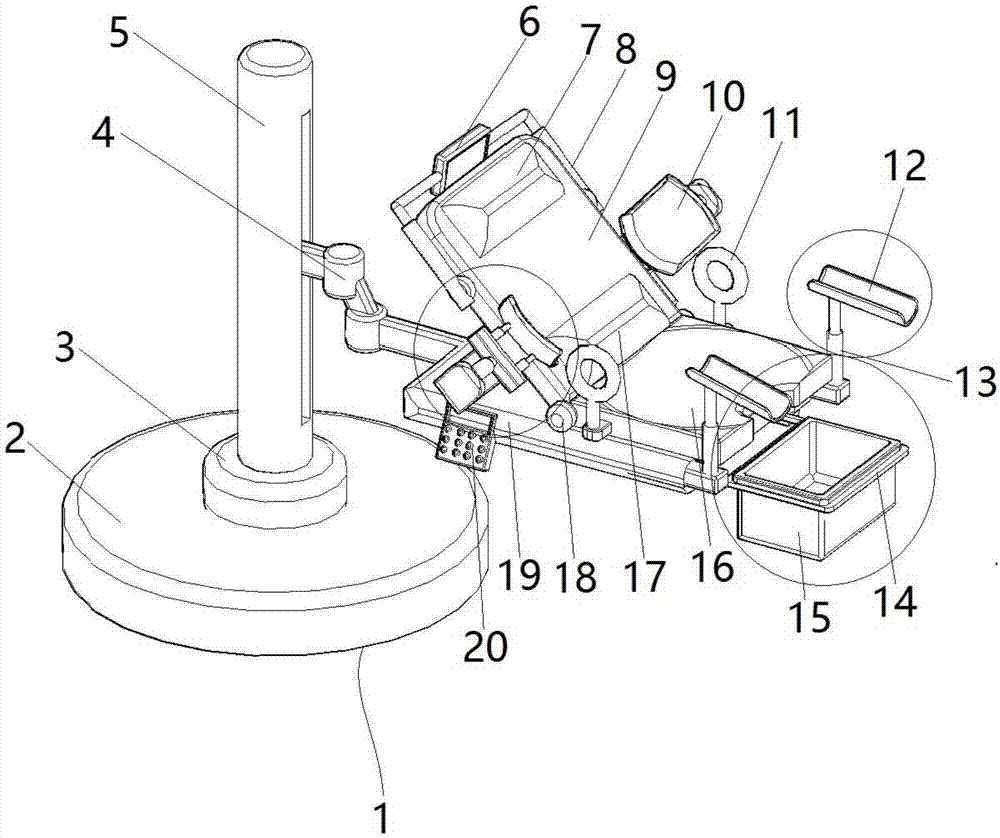

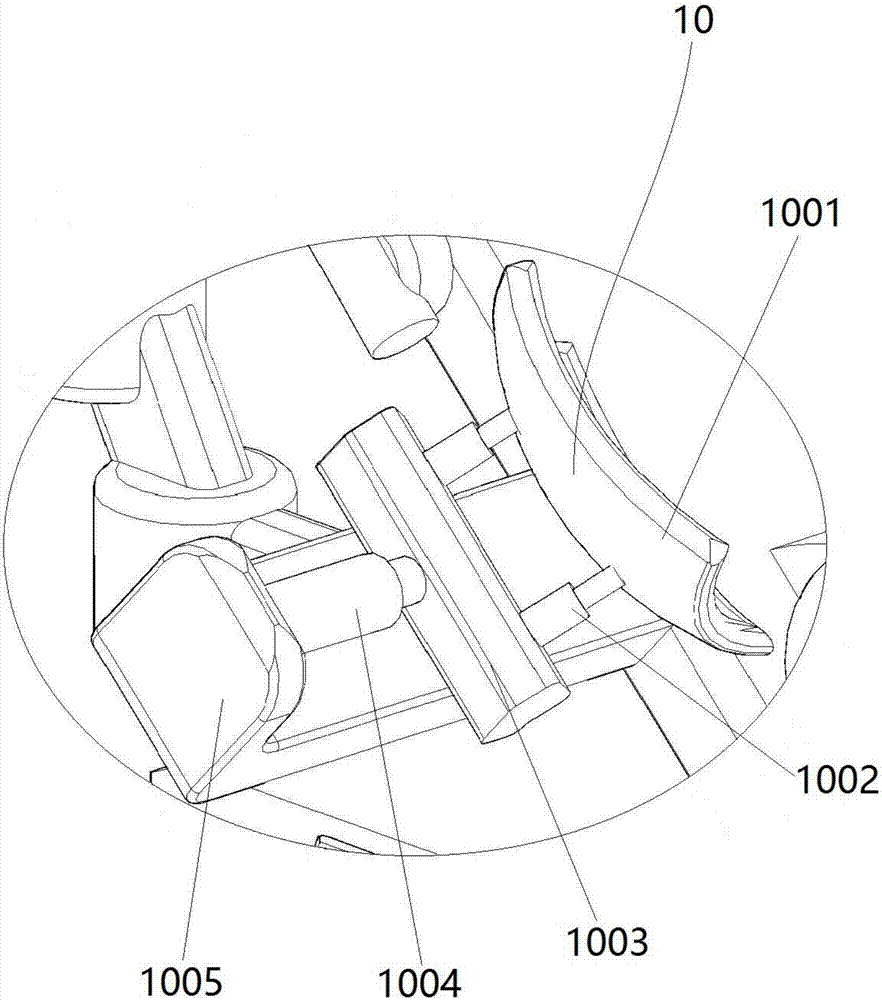

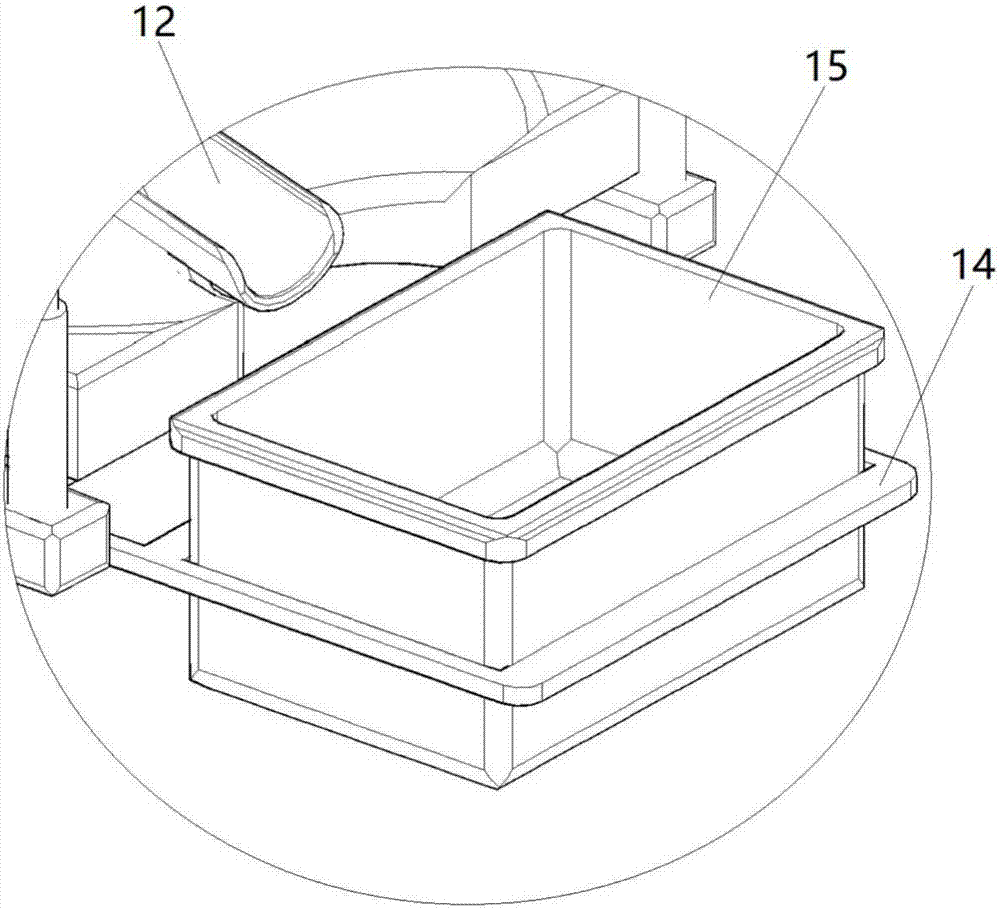

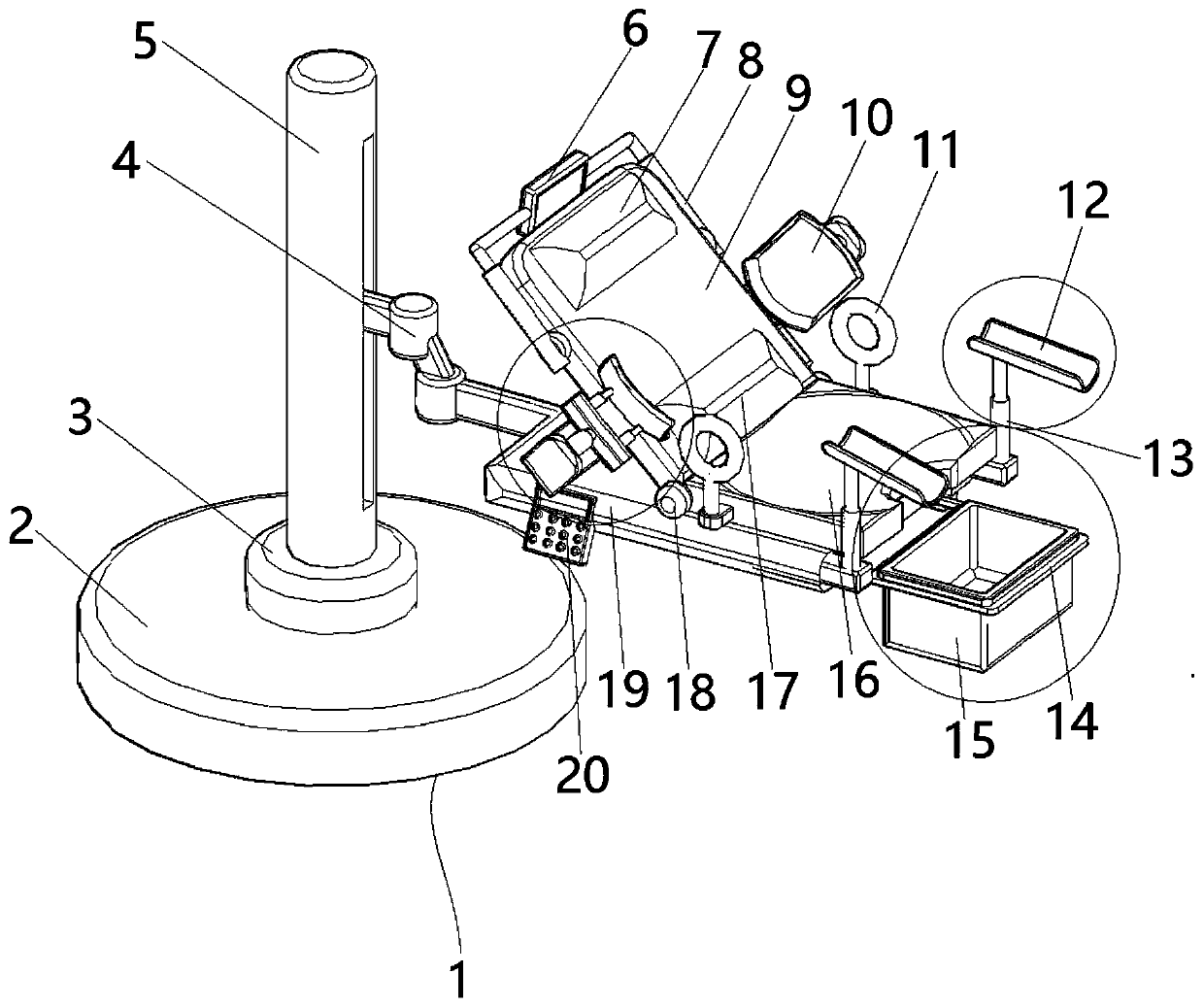

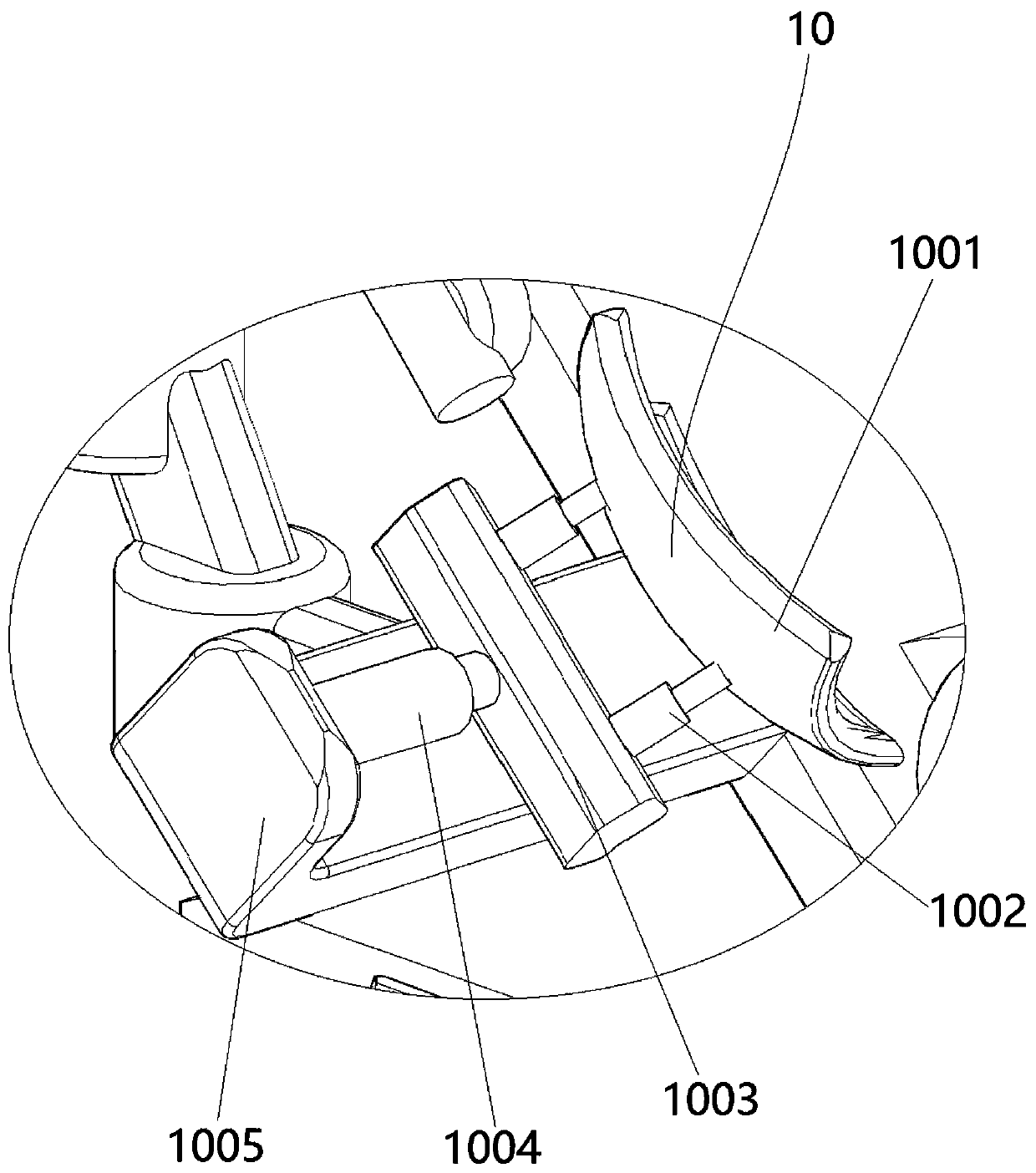

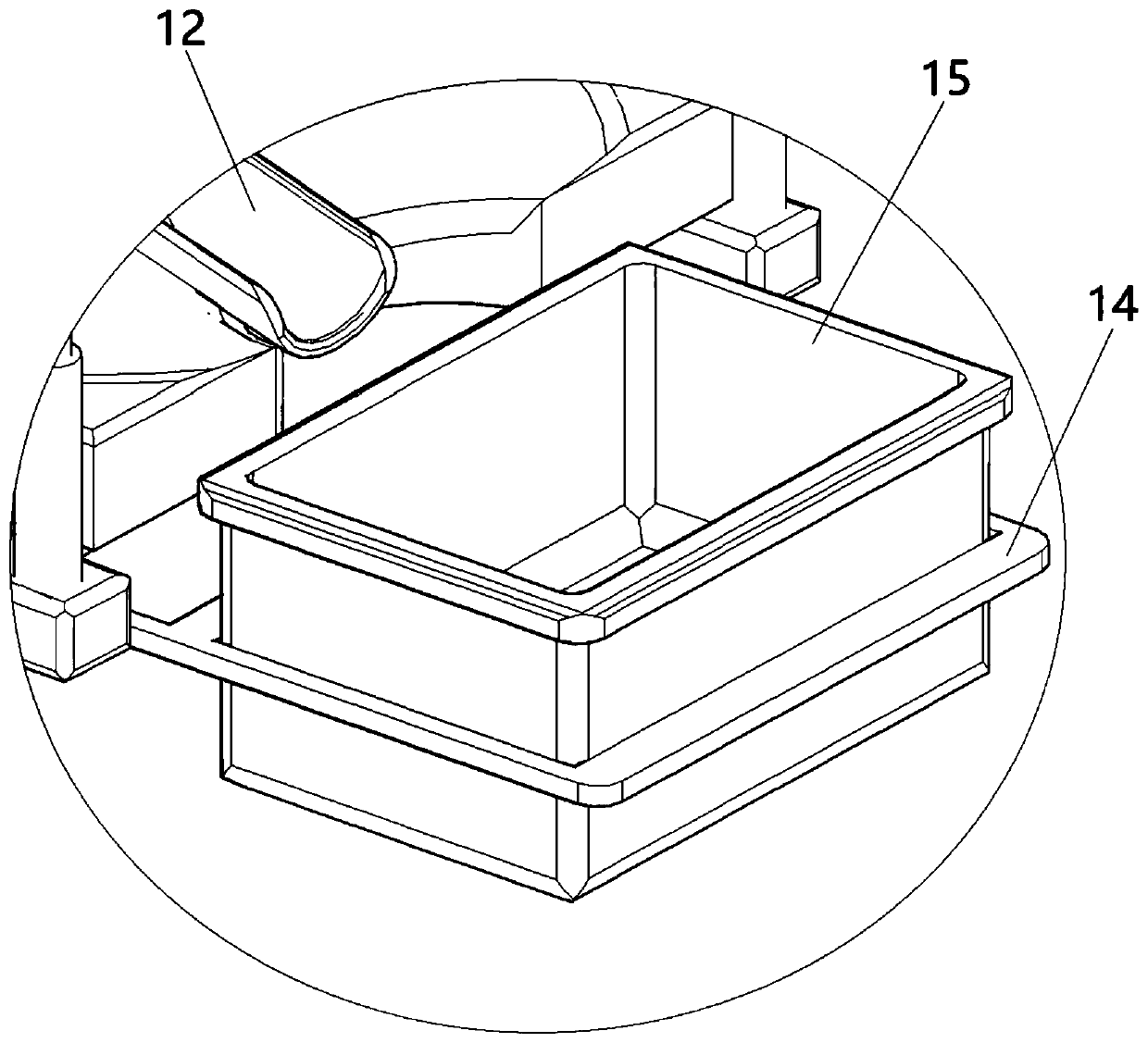

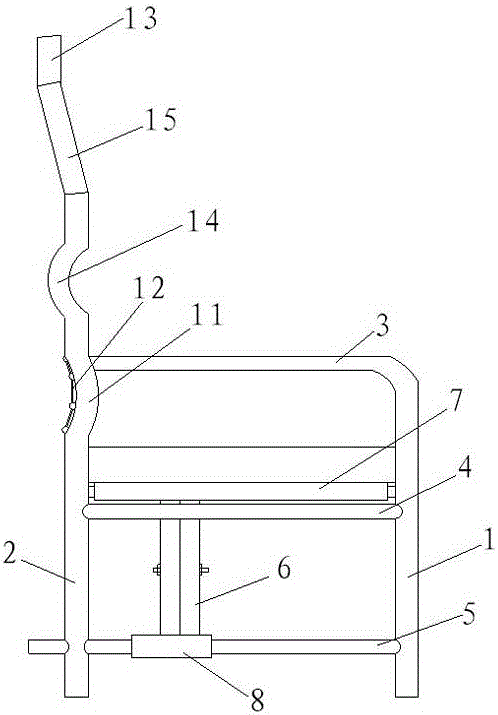

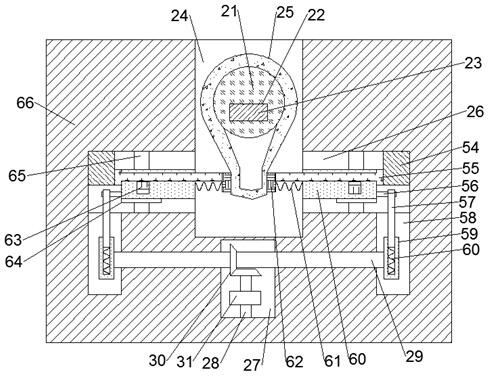

Special prenatal diagnosis bed for pregnant women used

ActiveCN107951660AEasy to operateSuitable for placementOperating tablesDiagnosticsSpecial bedHydraulic cylinder

The invention relates to a special prenatal diagnosis bed for a pregnant woman. The special prenatal diagnosis bed includes a counterweight base, a rotating motor and pregnant belly holding devices; the counterweight base is arranged on the body of the special bed; the rotating motor is fixed to the upper end of the counterweight base by bolts; a supporting lifting column is arranged at the upperend of the rotating motor in a transmission mode; a connecting supporting rod is movably installed on the side wall of the supporting lifting column; a bottom supporting platform is fixedly arranged at the end of the connecting supporting rod; the pregnant belly holding devices are symmetrically arranged on the side walls of the two ends of a backrest; display screen lifting hydraulic cylinders are symmetrically arranged on and rotatably connected to the side wall of the backrest; a leisure display screen is movably fixed to the upper ends of the display screen lifting hydraulic cylinders. Thespecial prenatal diagnosis bed for the pregnant woman is provided with leg support plates which are of arc-shaped groove structures, and the length of each leg support plate is 50 centimeters. The leg support plates fit the curved structures of the human legs, are in line with ergonomics and make the legs more comfortable during placement, and the length fits the majority's placement.

Owner:梁山县人民医院

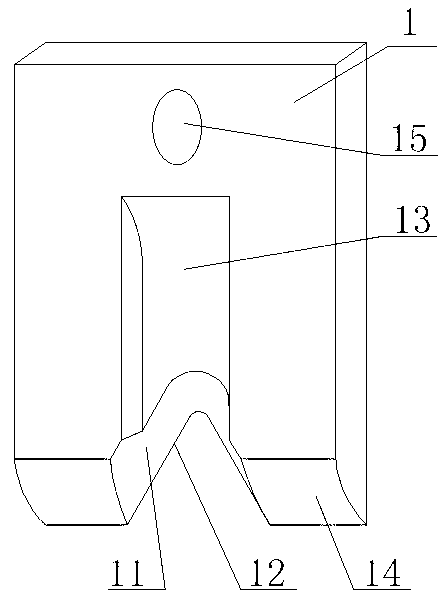

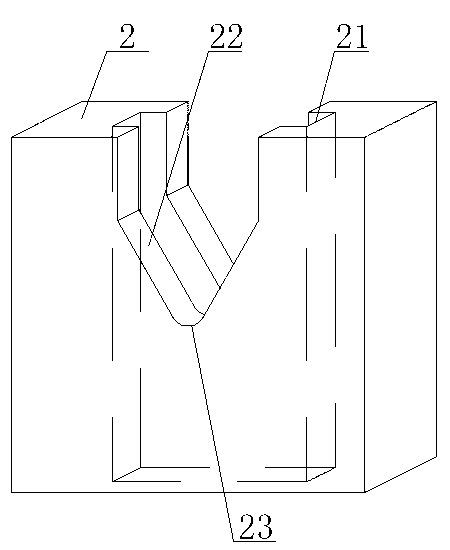

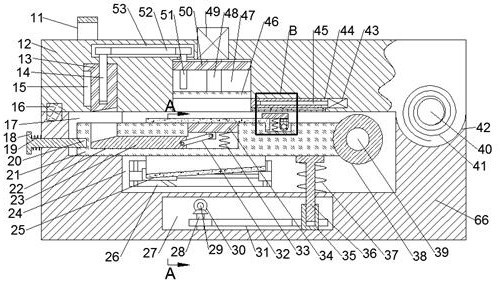

Cable cut-off tool

The invention discloses a cable cut-off tool, and belongs to a mechanical technology. The cable cut-off tool mainly comprises a blade and a combined tool seat which are matched with each other, wherein an inverted V-shaped blade cutting edge angle is formed at the lower end of the blade; a blade cutting edge is formed on the blade cutting edge angle; a blade sliding chute matched with the blade is formed on the combined tool seat; a cable withdraw slot and a groove are formed on the blade; and a tool seat cutting edge angle and a supporting base are arranged on the combined tool seat. The cable cut-off tool is ingenious in design, simple in structure, small in size and convenient to operate; due to the unique structural design, the cutting effect is greatly enhanced; clean and flat cutting is guaranteed when a cable or particularly a special cable is cut, so that cutting residues are avoided; moreover, cutting energy consumption is greatly reduced; and meanwhile, the service life is greatly prolonged.

Owner:CHENGDU QIPING TECH CO LTD

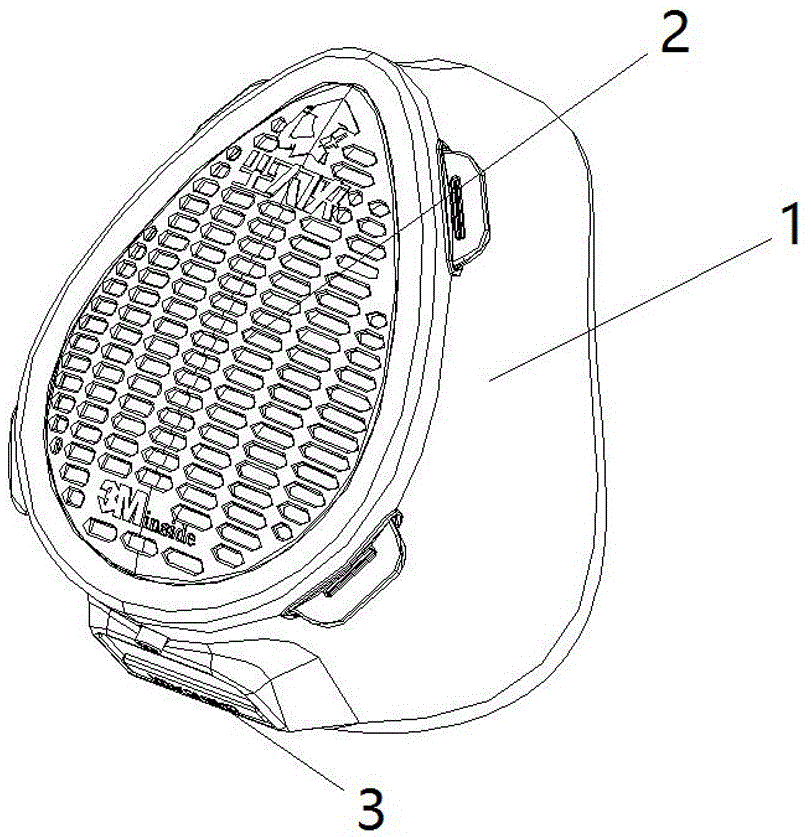

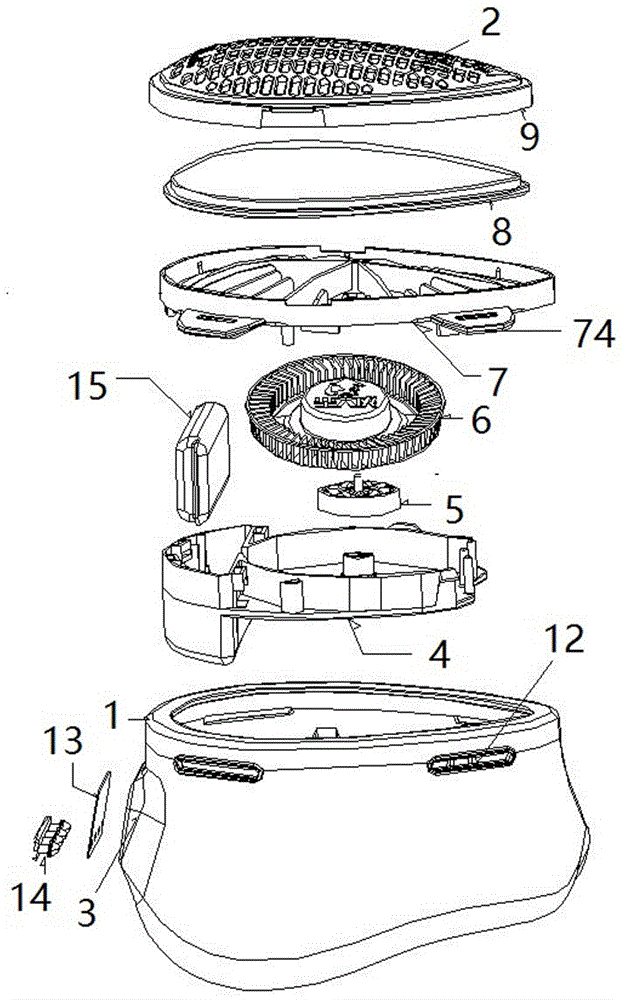

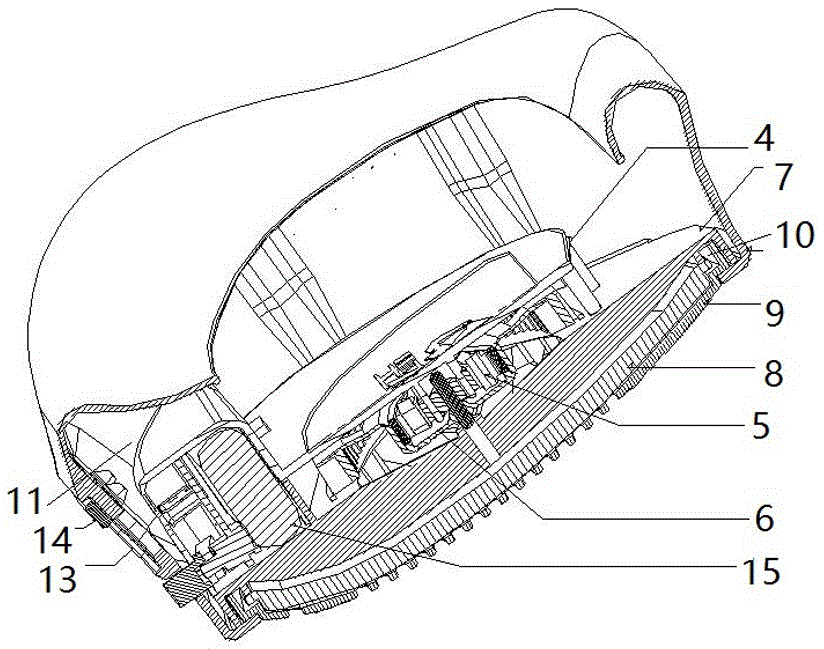

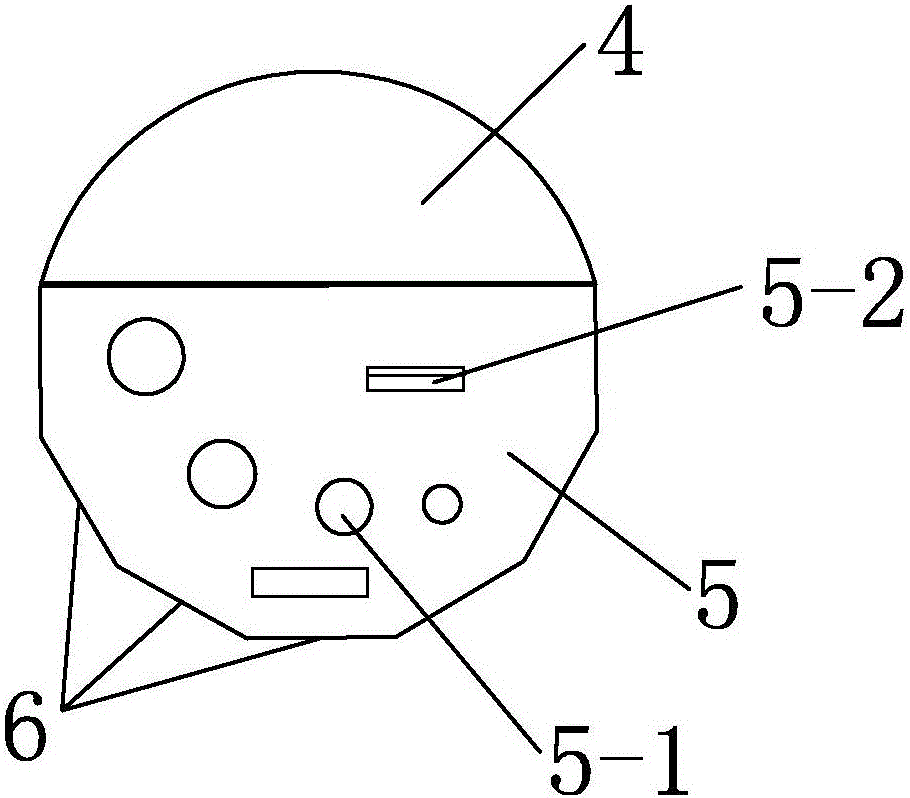

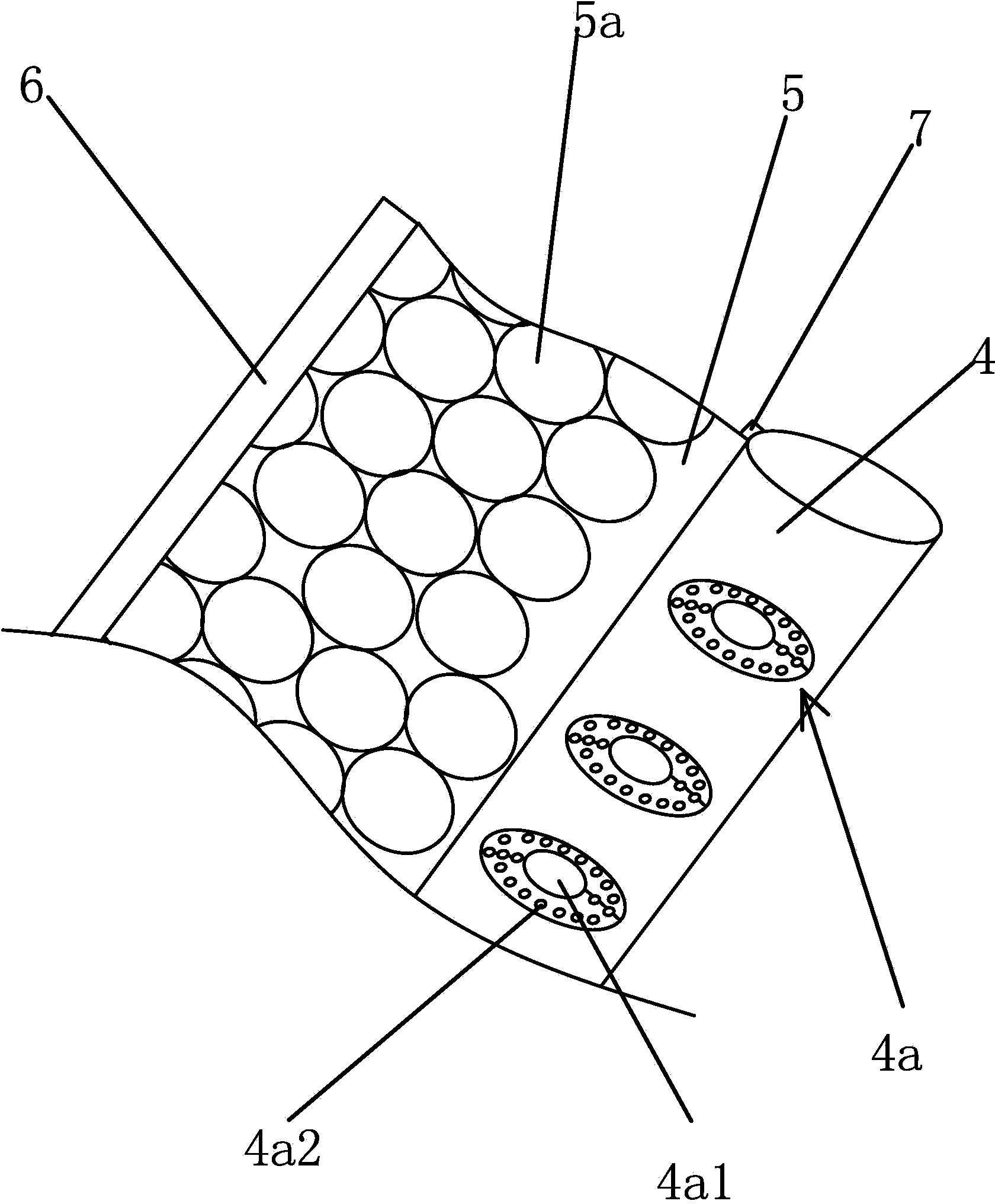

Three-dimensional air supply protective mask

The invention discloses a three-dimensional air supply protective mask which comprises a face mask jointed to the face, an air inlet and an air outlet, wherein a filtering device is arranged in the face mask; the filtering device comprises a base; an electrode and a wind wheel are arranged in the base; a support framework is arranged above the base; a filter screen and a filter screen shell are sequentially arranged on the support framework; the air inlet is arranged on the filter screen shell; the air outlet is arranged at one side of the face mask; the upper end of the face mask and the base form an air inlet channel; and the lower end of the face mask and the base form an air outlet channel. The whole mask is in a water drop shape so as to accord with the shape of the human face; the mask adopts a reverse silica gel face mask which has a good overall sealing property; and the air inlet channel and the air outlet channel are separately designed so as to ensure that inhaled air is filtered fresh air, the condition of air resorption is avoided, soft air can be obtained, and the comfort level can be increased.

Owner:惠州市亚鑫实业有限公司

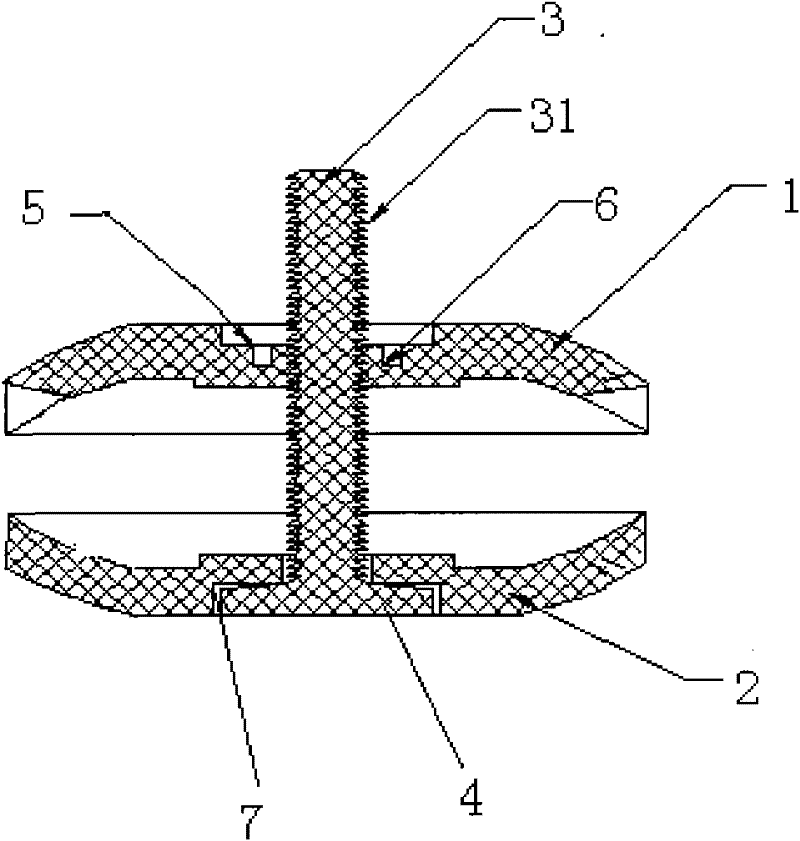

skull lock

The invention discloses a skull lock, which comprises an upper lock piece, a lower lock piece and a lock core, the lock core can fix the relative position between the upper lock piece and the lower lock piece, and the lock core passes through the lower lock piece and the upper lock piece in turn , the end of the lock cylinder close to the lower lock piece forms a stopper, which is the big end of the bolt, and the stopper stops on the side of the lower lock piece back to the upper lock piece, so that one end of the lock cylinder is fixed on the lower lock piece, and the outer surface of the lock cylinder There are teeth facing the lower lock plate, and the teeth on the outer surface of the lock cylinder are clamped into the upper lock plate, so as to enhance the locking force, the uniformity of the locking force and the quickness of locking, and reduce the operation time. The skull lock has a simple structure, can be quickly locked, has a better locking effect, and is not easy to fall off.

Owner:SUZHOU SHIP BIOLOGICAL TECH

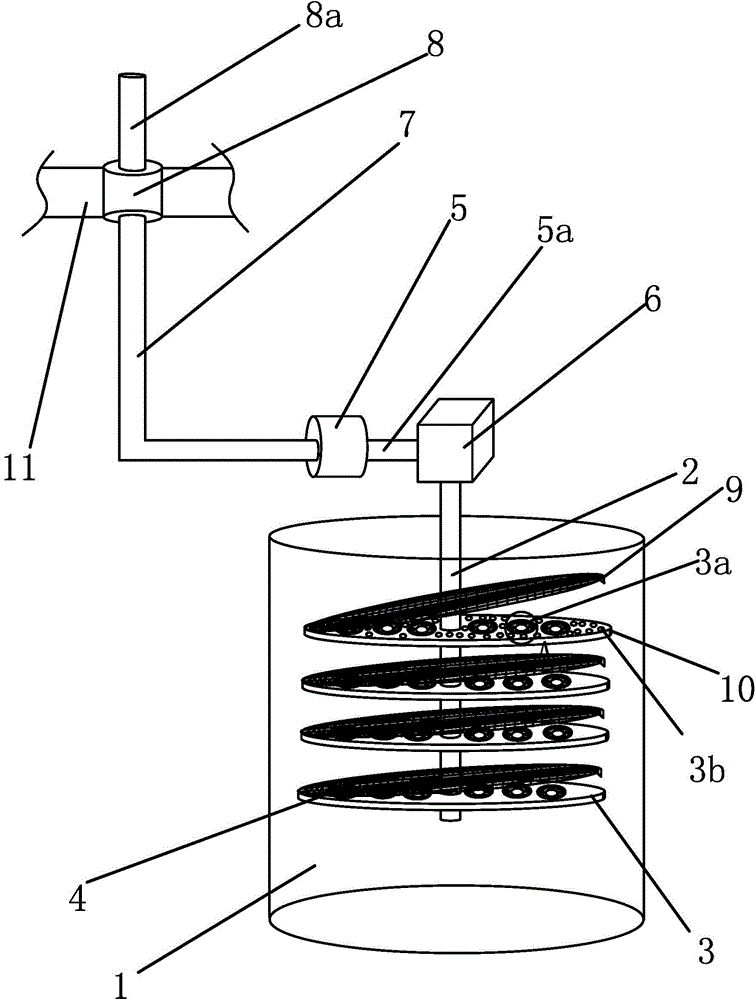

Axis driving type optical lens cleaning equipment

InactiveCN104307828APrevent escapeWon't wear outFlexible article cleaningCleaning using toolsElectric machineryEngineering

The invention provides axis driving type optical lens cleaning equipment, and belongs to the field of optical lens processing equipment. The cleaning equipment comprises a cleaning barrel, wherein a material carrying mechanism is arranged in the cleaning barrel; the material carrying mechanism comprises a material carrying shaft and material carrying plates; a lens trough is formed in the upper side of each material carrying plate; each lens trough is in a reduced orifice shape from top to bottom, and bottom holes penetrating through two sides of the material carrying plate are formed in the bottom center of the lens trough; a first limber hole is formed in each lens trough; a second limber hole is formed in each material carrying plate; each material carrying plate is hinged to a rubber mesh; one end of the rubber mesh is hinged to one end of the corresponding material carrying plate; the upper end of the material carrying shaft is connected with a driving motor; a crank sliding block mechanism is arranged between the driving motor and the material carrying shaft; the sliding block of the crank sliding block mechanism is connected to the material carrying shaft; the crank of the crank sliding block mechanism is connected to the motor rotating shaft of the driving motor; the motor casing of the driving motor is fixedly connected with a lifting rod; one end of the lifting rod is connected with a linear motor. The cleaning equipment is comprehensive in cleaning effect, and excellent in cleaning effect.

Owner:中山市吉尔科研技术服务有限公司

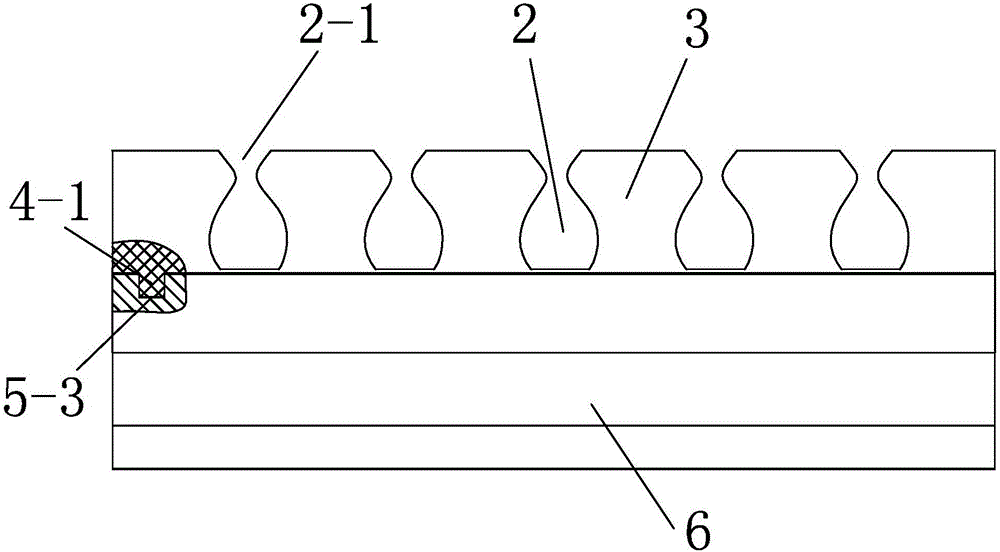

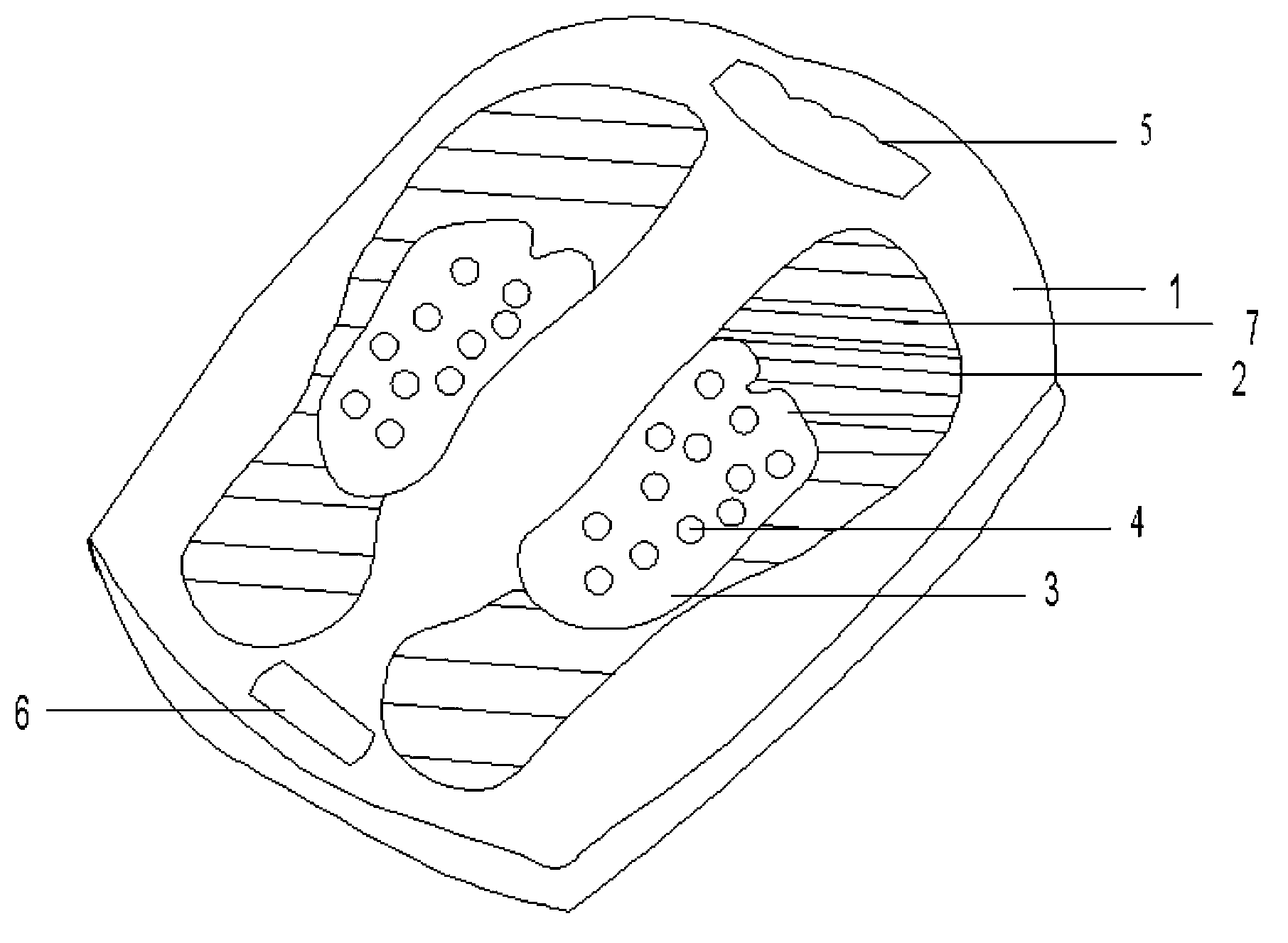

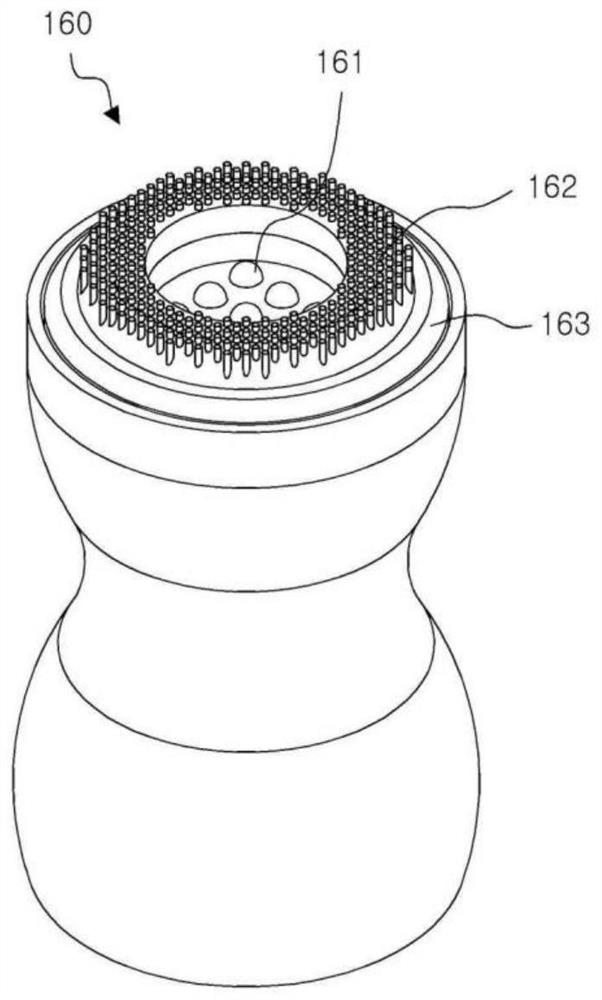

Massage insole

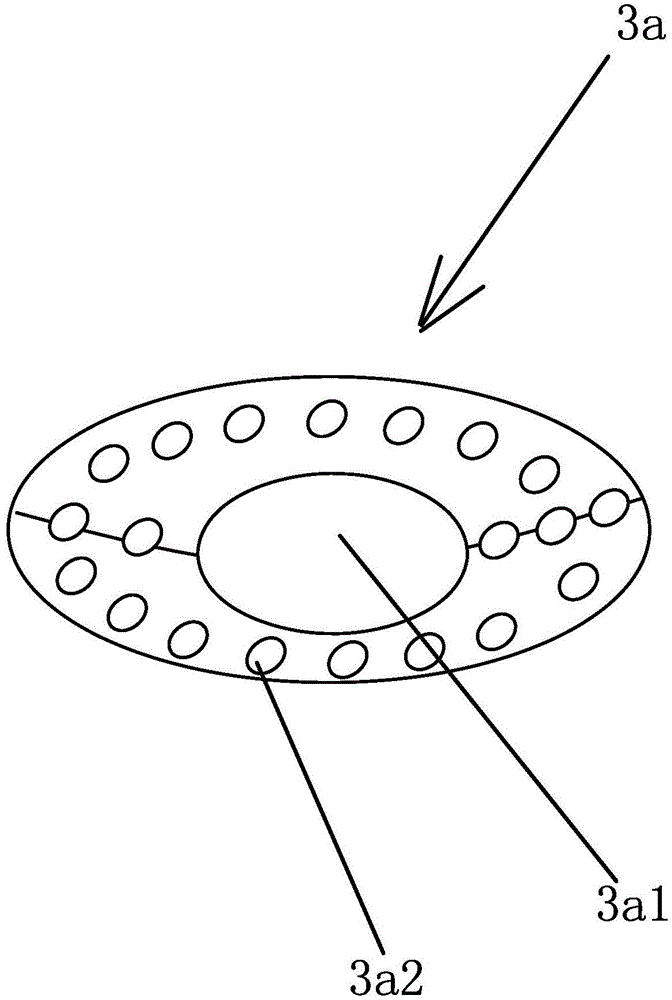

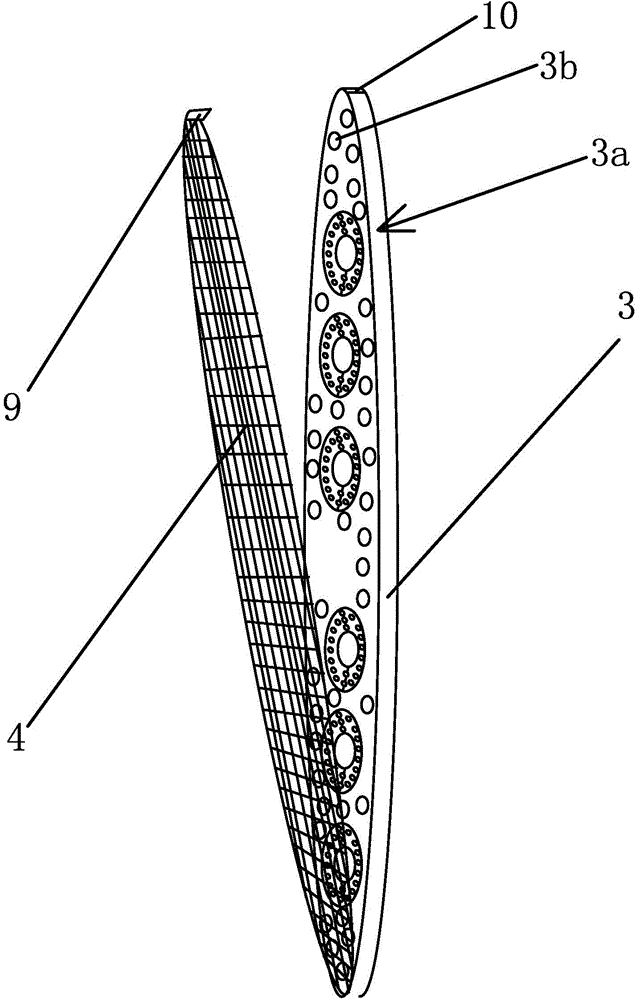

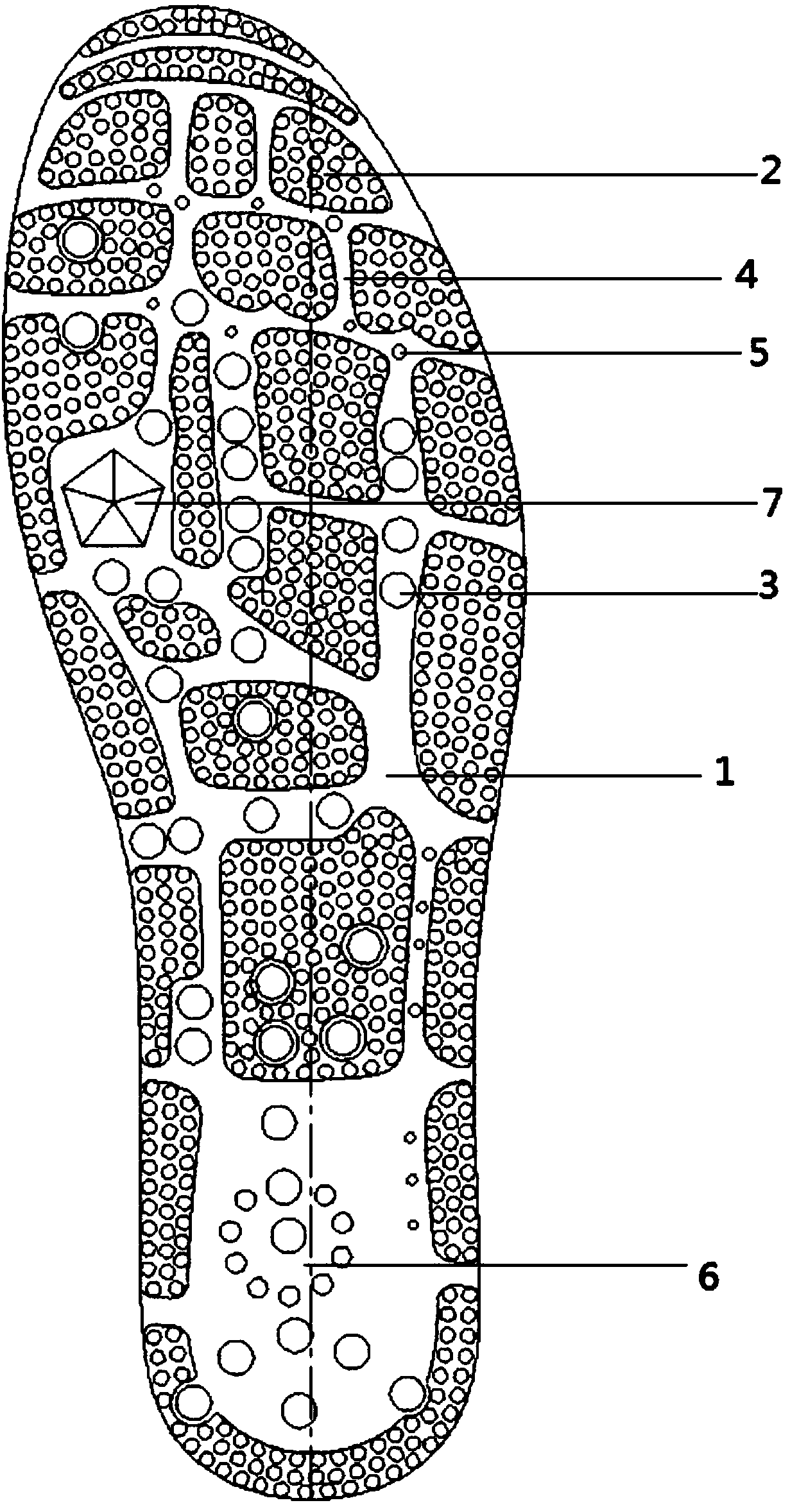

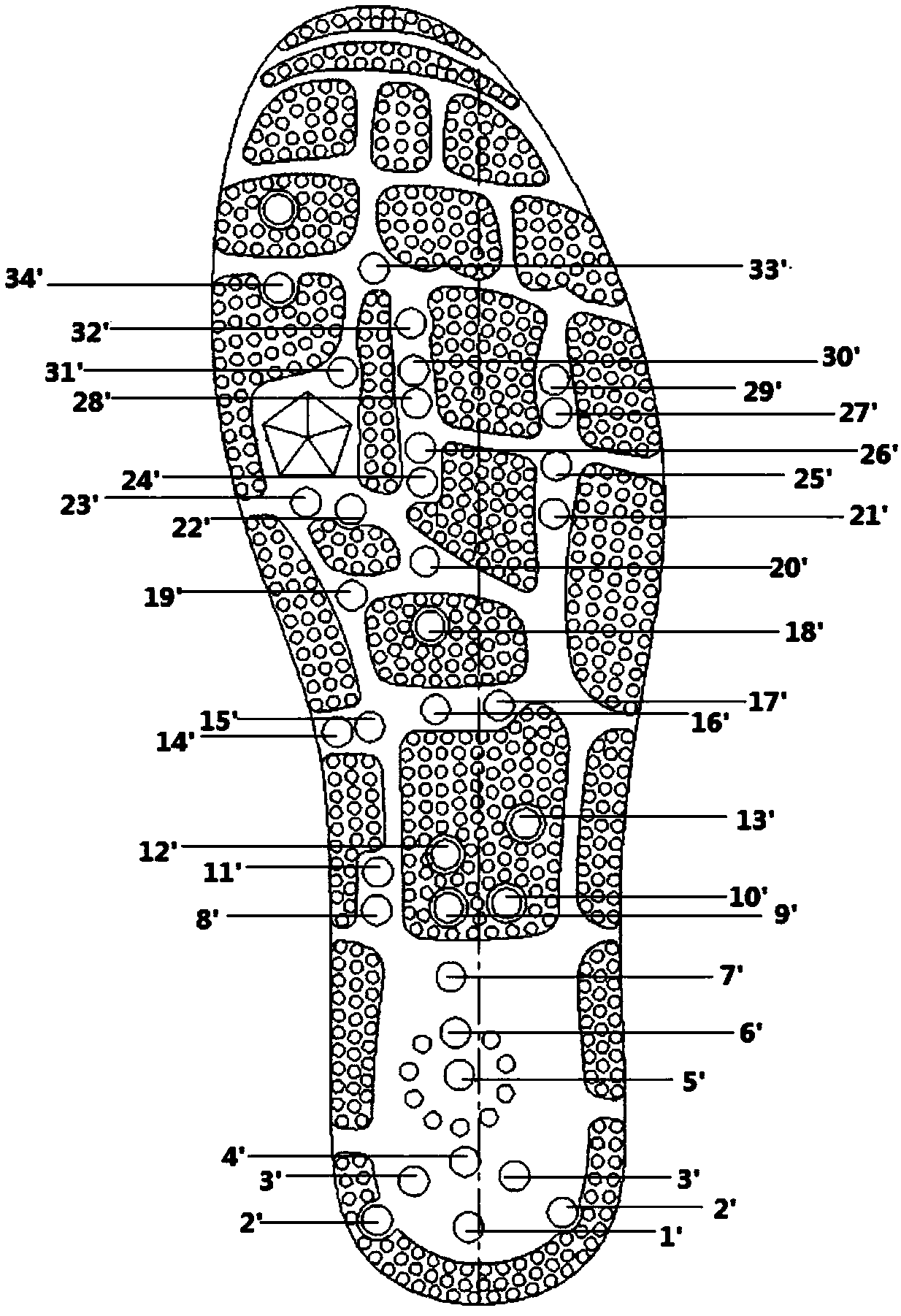

PendingCN108113118AGuaranteed breathabilityGuaranteed softnessInsolesDevices for pressing relfex pointsMassagePhysical therapy

The invention discloses a massage insole, which comprises an insole main body, brush-shaped massage bulges and a spherical massage bulge arranged on the insole main body; each brush-shaped massage bulge comprises a platform raised out of the insole main body and small bulges evenly arranged on the platform; the brush-shaped massage bulges are arranged at the edge and sole of the insole main body,a groove is arranged between the brush-shaped massage bulges; the brush-shaped massage bulges are big bulges of which top ends are spherical, the tangential area is more than that of the small bulgeson the brush-shaped massage bulges; the height of the spherical massage bulge is equal to the brush-shaped massage bulges, the spherical massage bulge is corresponding to acupuncture point at the foot bottom, and arranged in the groove between the brush-shaped massage bulges or in the middle of the brush-shaped massage bulges. The massage insole is more reasonable in design, able to meet the footbottom shape, and good in breathability. Through the massage bulges with different shapes and heights, the insole has very good softness and comfort level; meanwhile, targeted massage can be performed on the acupuncture point at the foot bottom.

Owner:JIANGSU YIBEI IND

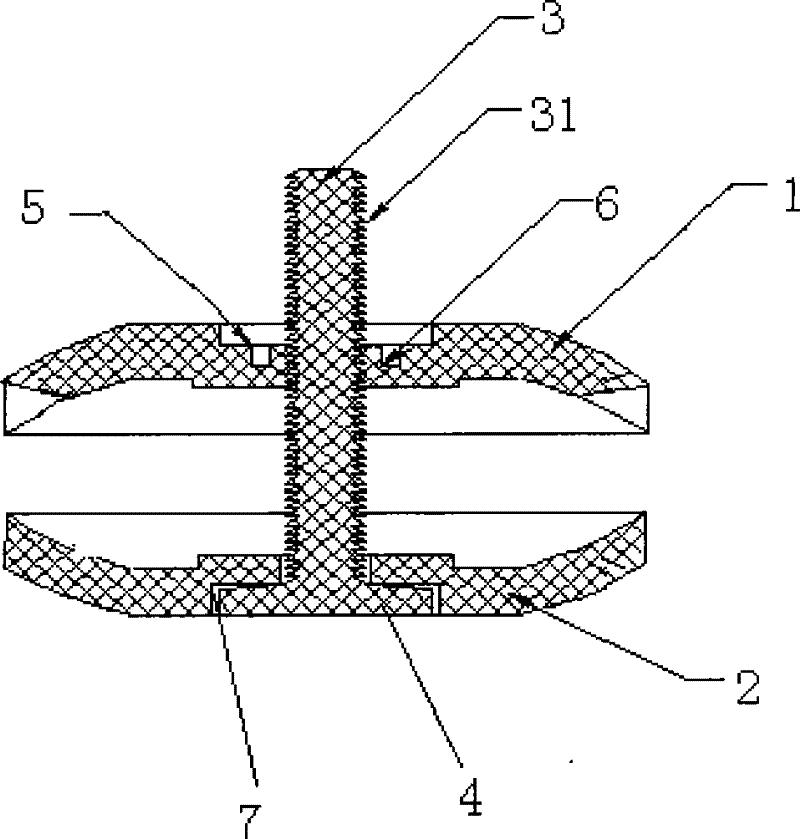

Comb-shaped holding frame formed by plastic and manufacturing method thereof

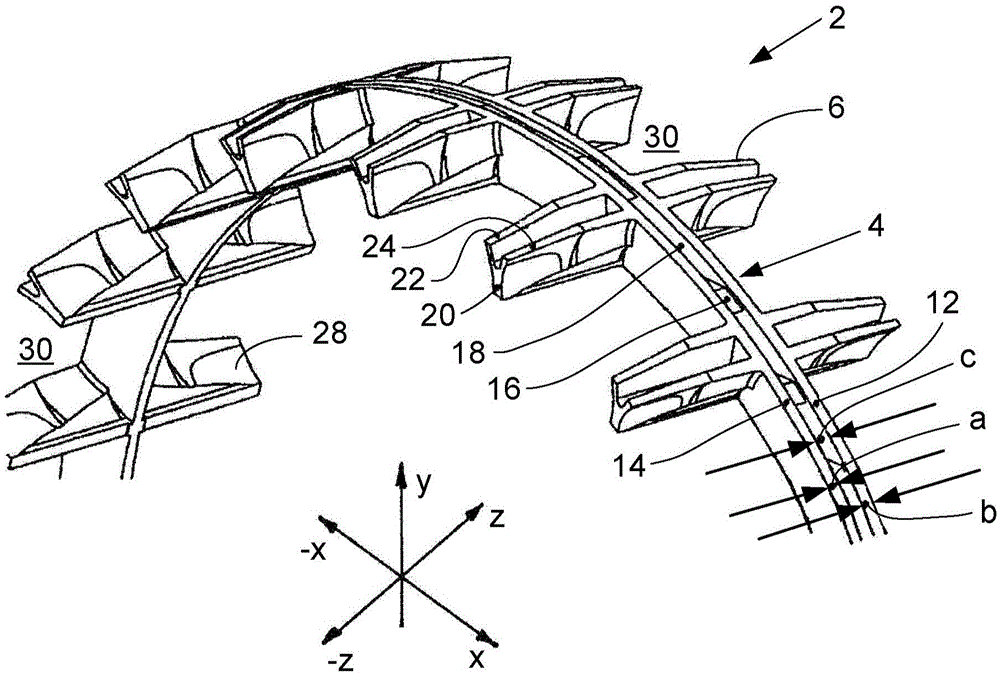

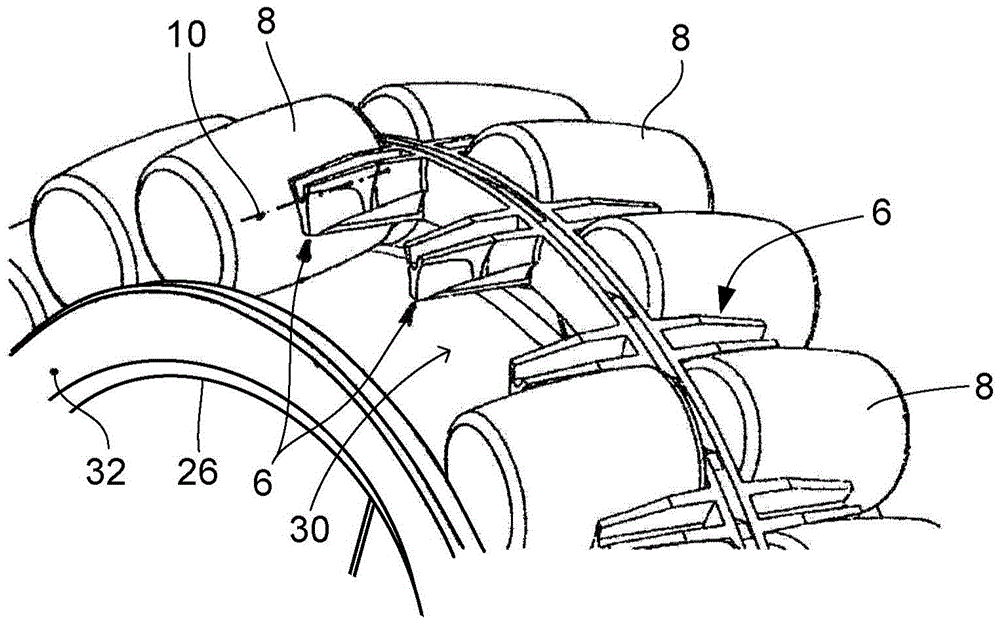

ActiveCN105465181AMeet strength requirementsAvoid deformationRoller bearingsShaftsEngineeringUltimate tensile strength

The invention relates to a comb-shaped holding frame formed by plastic and a manufacturing method thereof. The comb-shaped holding frame comprises a holding frame ring for beam frames corresponding to attached rolling bodies in number. The beam frames are projected from the holding frame ring and maintain and guide the rolling bodies along a generatrix. In order to realize different strength requirements of the holding frame ring and the beam frames and avoid deformation so as to realize the same wall thickness in all regions of the holding frame ring, the holding frame ring is formed by a plurality of annular disks which are identical in wall thickness and are coaxially arranged, two adjacent annular disks are connected with each other by means of a plurality of separators arranged therebetween, the beam frames are configured to extend axially and have side wing strip-shaped bars matched with the rolling bodies in shape, and the wall thickness of wall elements forming the strip-shaped bars is identical with the thickness of the annular disks as far as possible.

Owner:SCHAEFFLER TECH AG & CO KG

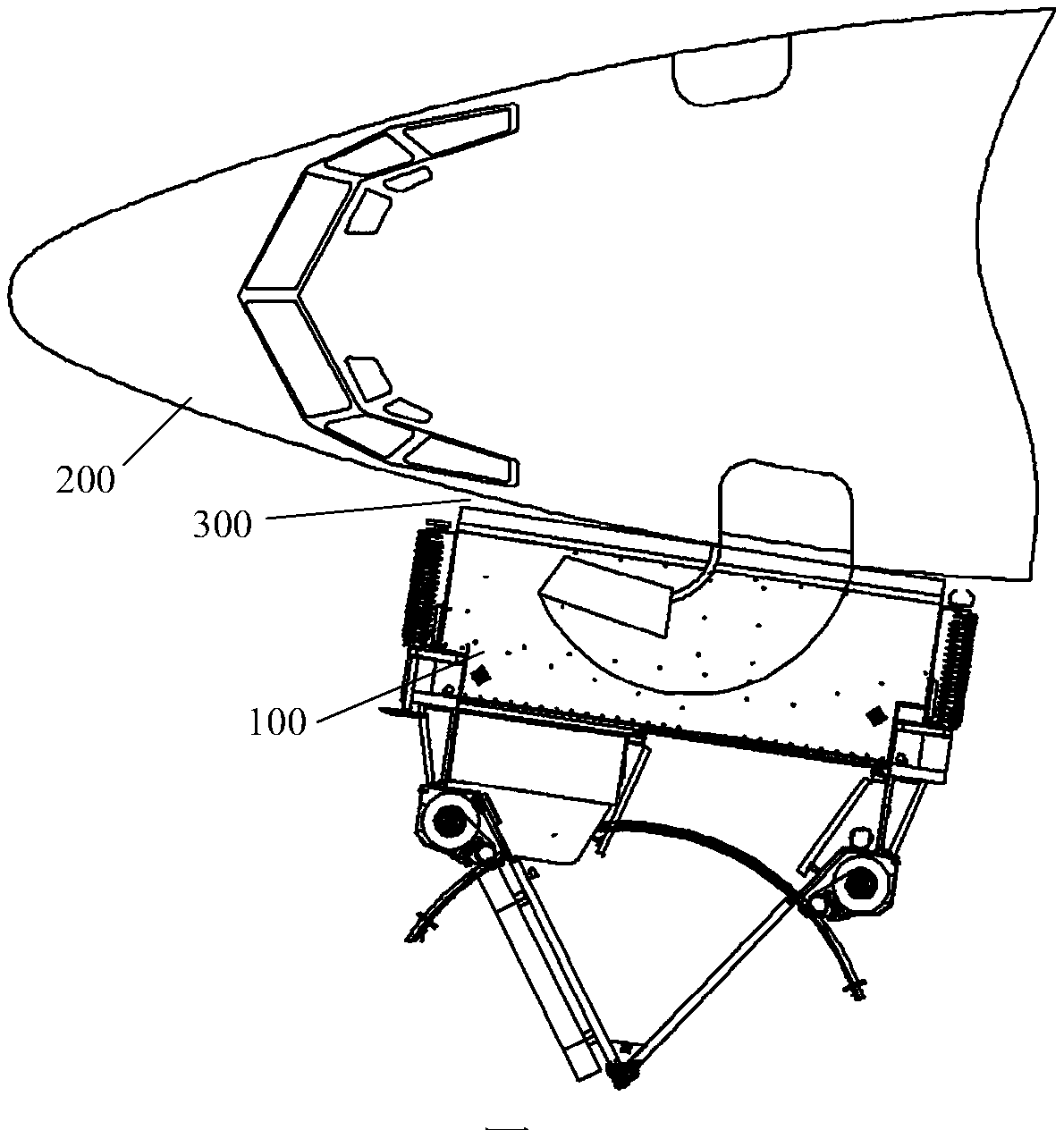

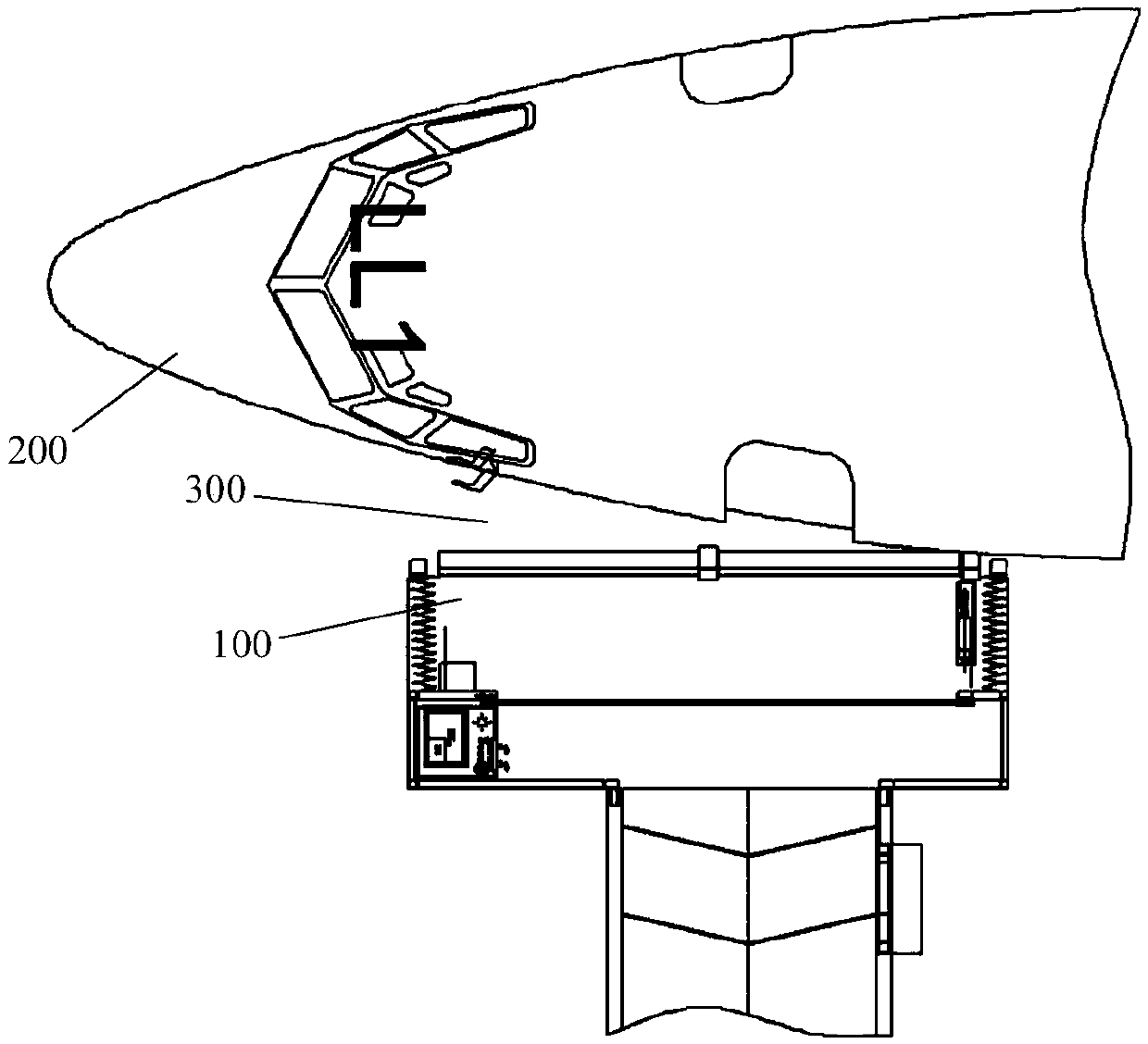

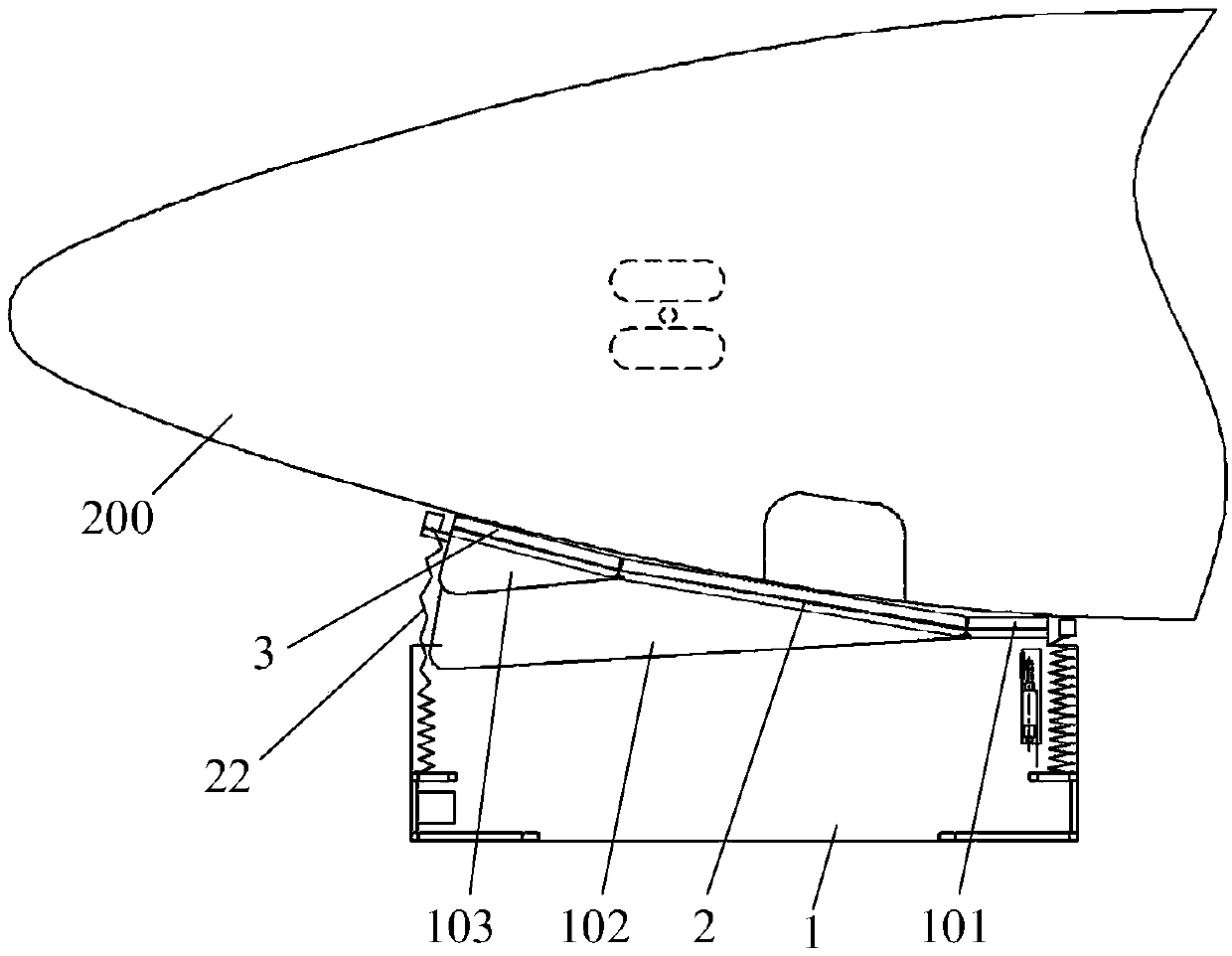

Boarding bridge and leading-edge structure of boarding bridge

The invention provides a boarding bridge and a leading-edge structure of the boarding bridge, and relates to the technical field of aviation. The leading-edge structure comprises a floor, a first leading edge, a first movable plate and a driving mechanism, and the floor comprises a front end used for butting joint an aircraft; the first end of the first leading edge is hinged to the front end, thesecond end of the first leading edge is a free end, and the first leading edge can rotate along the plane of the floor or the plane parallel to the floor; the first movable plate is connected with the first leading edge; the driving mechanism is used for driving the first leading edge to rotate along the plane of the floor or plane parallel to the floor to drive the first movable plate to extendout or be retracted to the front end. Through the leading-edge structure, the safety of the boarding bridge can be improved.

Owner:SHENZHEN CIMC TIANDA AIRPORT SUPPORT

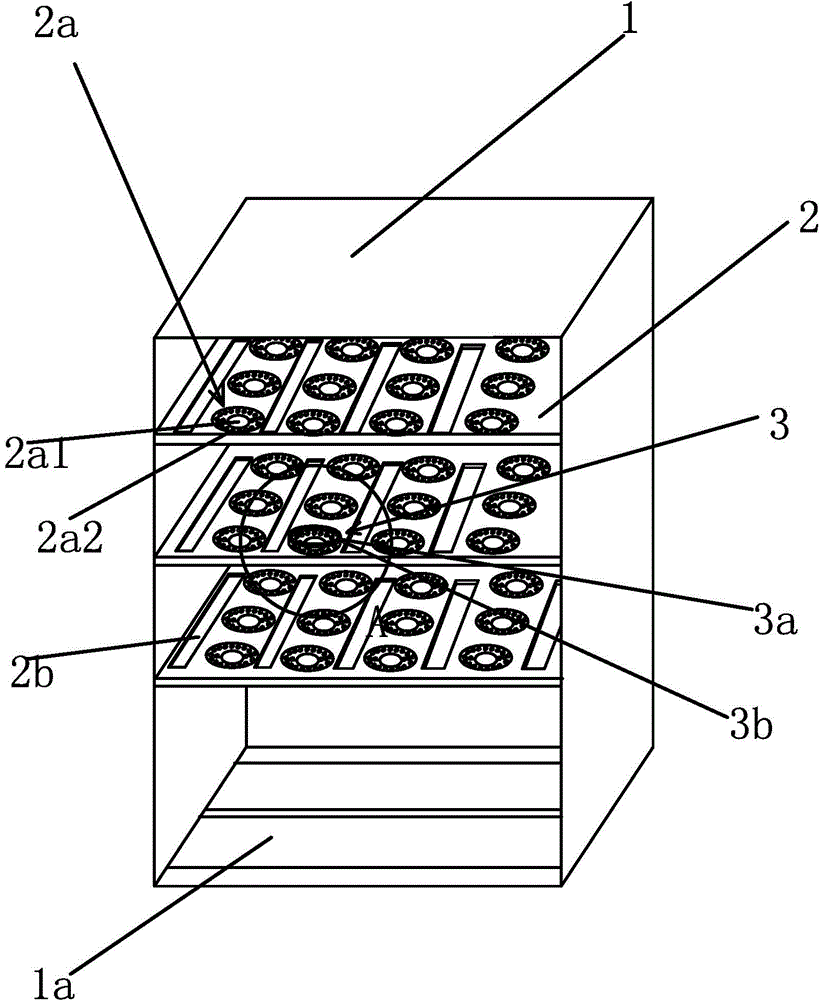

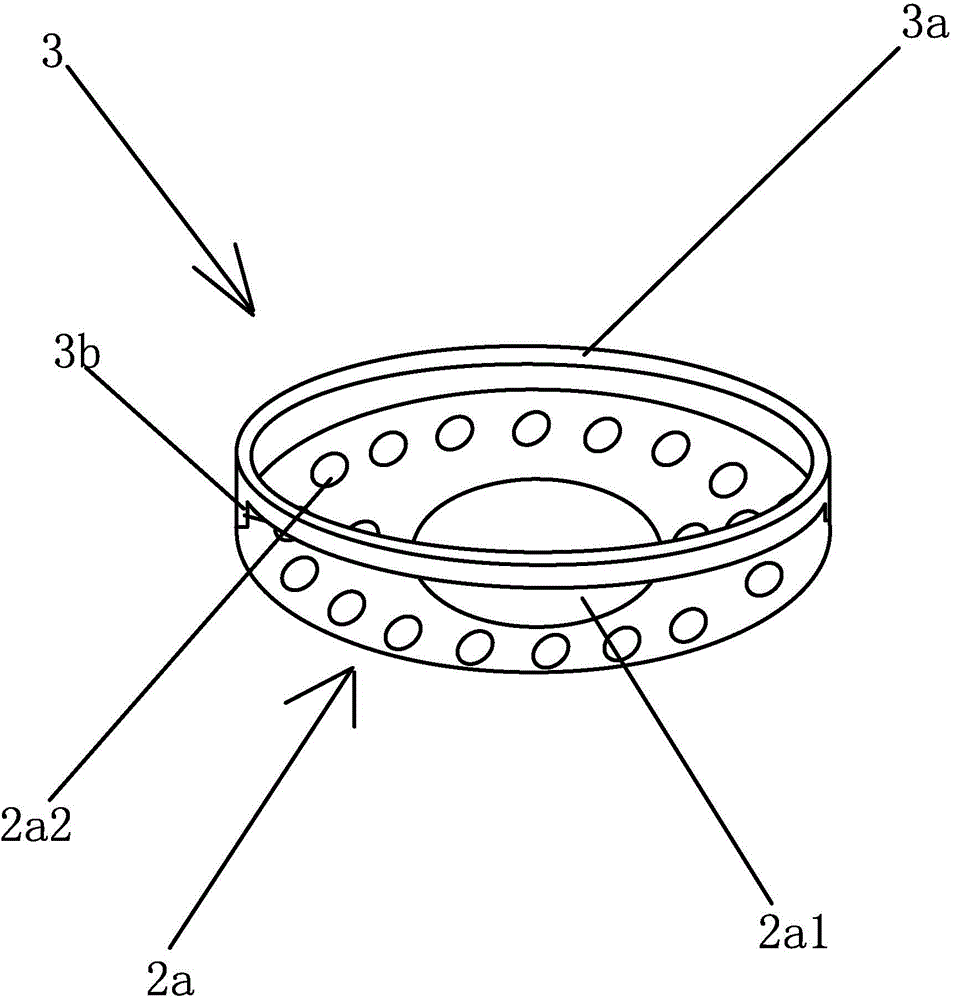

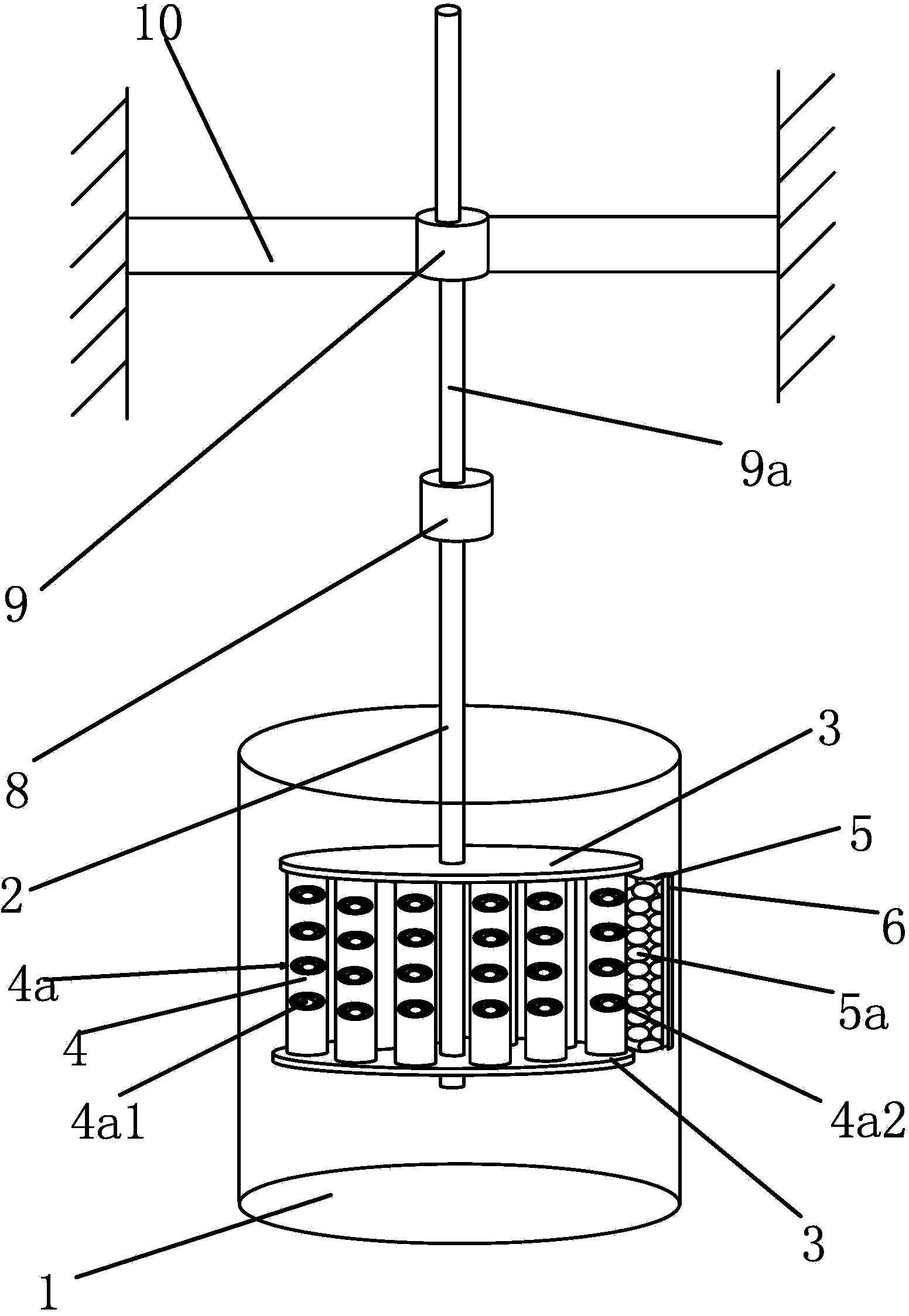

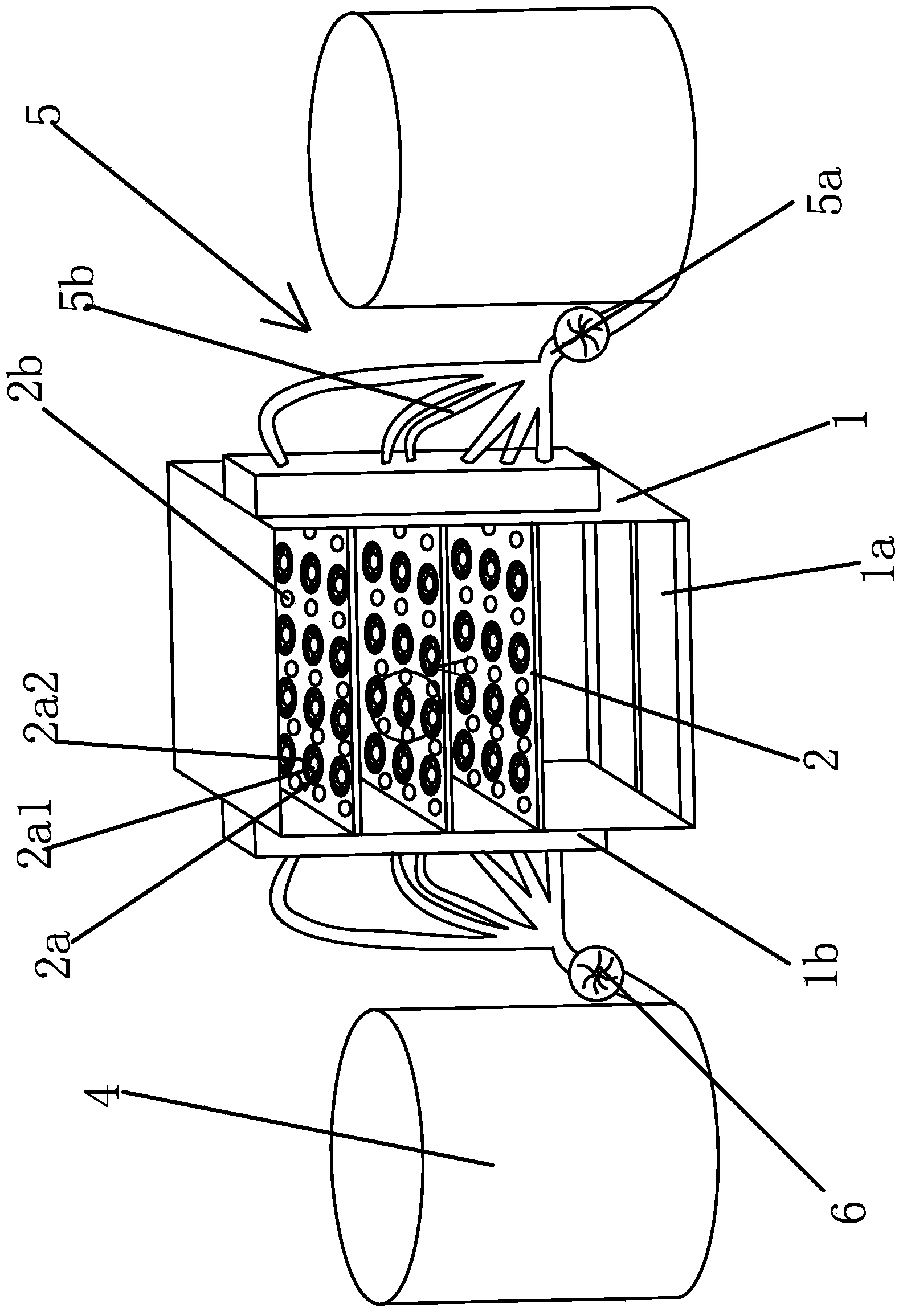

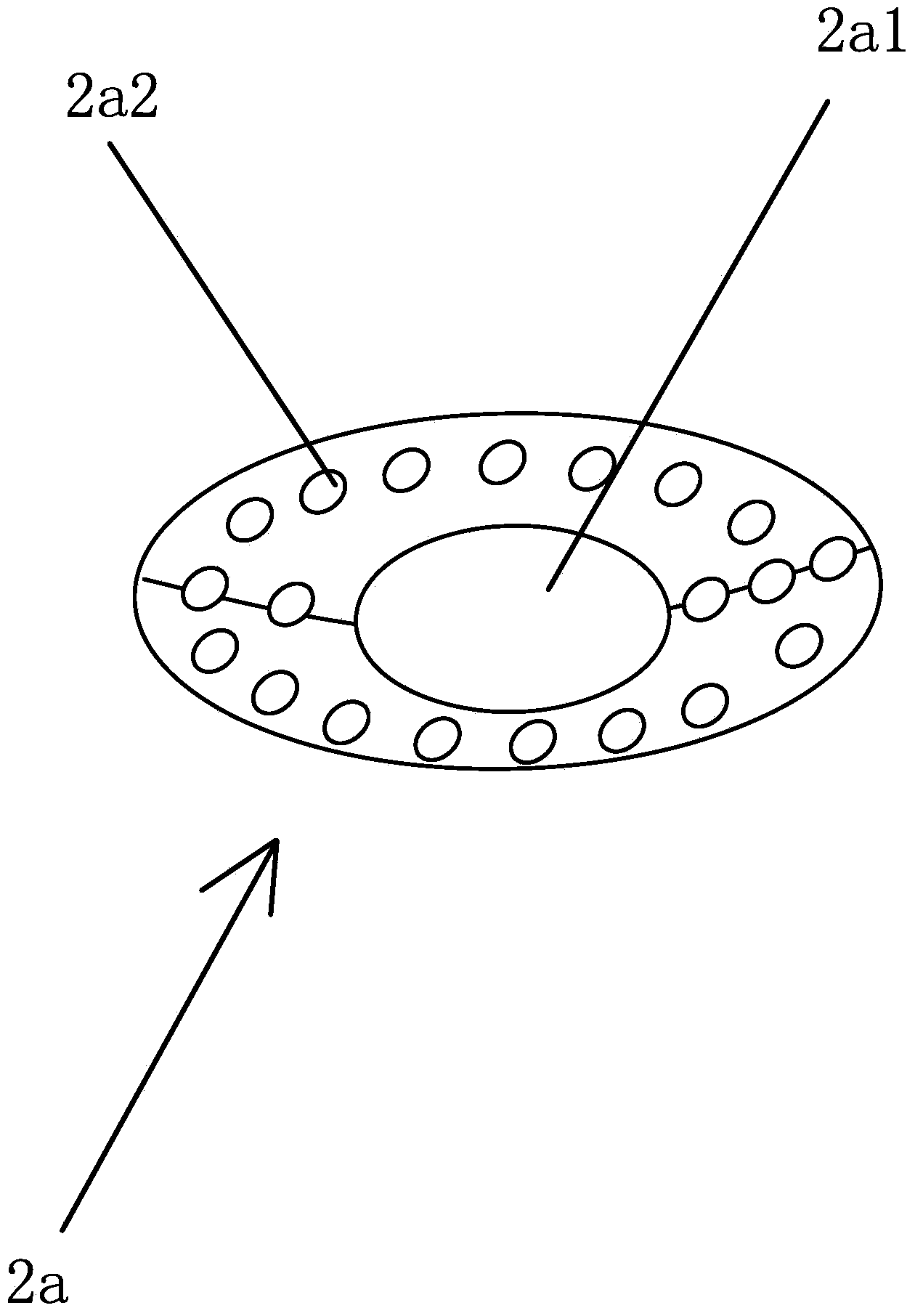

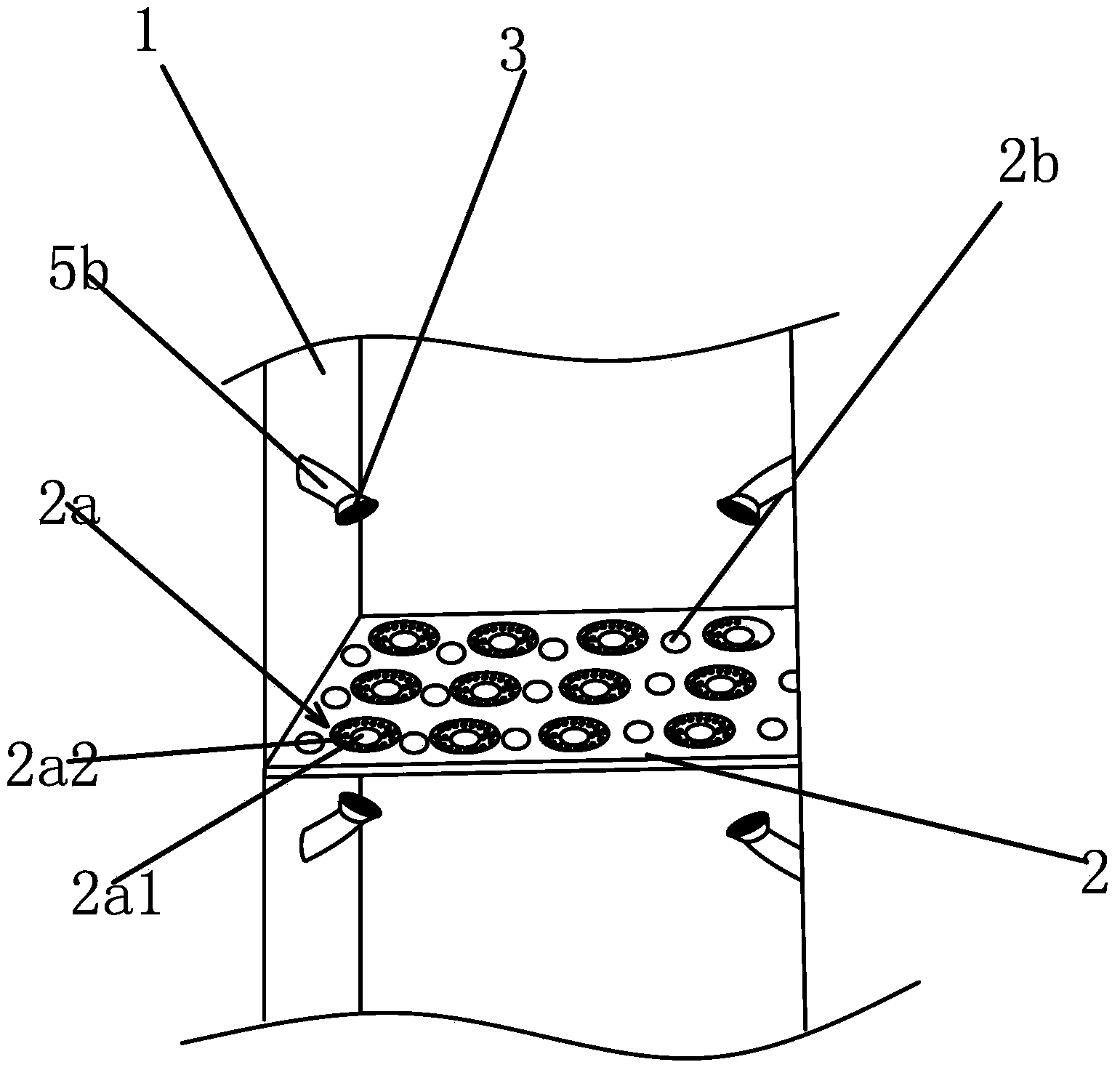

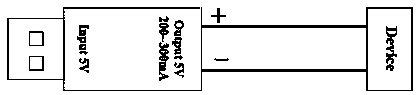

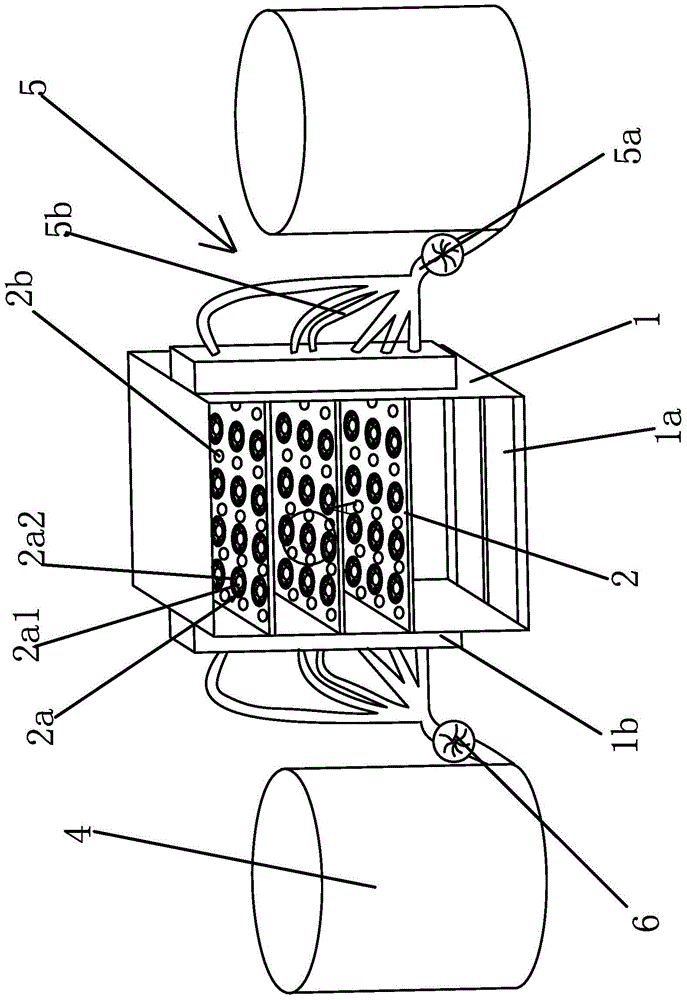

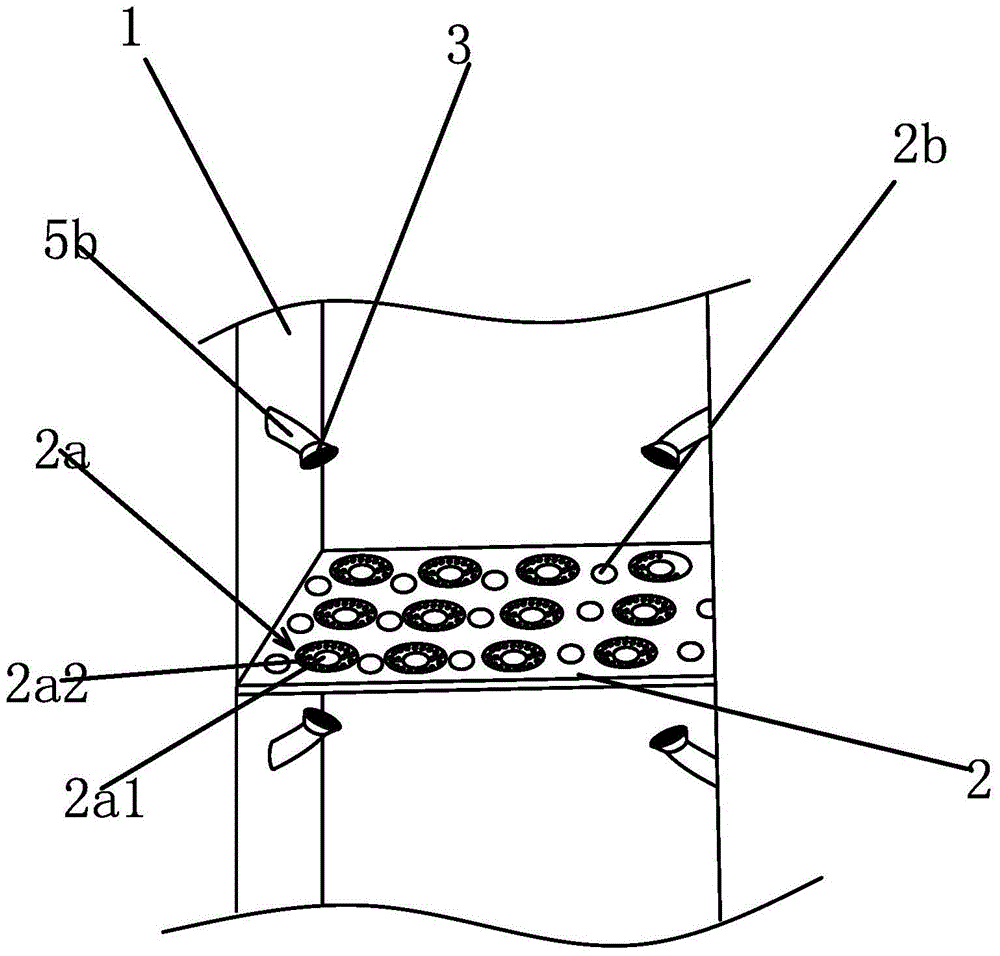

Device for cleaning optical lenses in batches

InactiveCN104438265AWill not cause shaking wearConform to shapeFlexible article cleaningCleaning using liquidsRubber ringSewage

The invention provides a device for cleaning optical lenses in batches, and belongs to the field of optical lens machining devices. The cleaning device comprises a box body. The box body is internally provided with lens plates. The lens plates are connected to the inner wall of the box body in a sliding mode. The upper sides of the lens plates are provided with lens grooves. The lens grooves are in a necked shape from top to bottom, and the centers of the bottoms of the lens grooves are provided with bottom holes for penetrating through the two sides of the lens plates. The lens grooves are provided with a plurality of water through holes for penetrating through the two sides of the lens plates. The lens grooves are further provided with protruding fixing devices. The fixing devices comprise annular rubber rings, the rubber rings are located over the lens grooves, rubber strips are arranged between the rubber rings and the lens grooves, one end of each rubber strip is fixed to the periphery of the corresponding lens groove, and the other end of each rubber strip is fixedly connected with the corresponding rubber ring. The lens plates are further provided with a plurality of strip-shaped through openings for penetrating through the two sides of the lens plates. The bottom, located below the lens plates, of the box body is provided with a plurality of strip-shaped sewage discharging openings. The cleaning device is high in cleaning strength and good in cleaning effect.

Owner:中山市吉尔科研技术服务有限公司

Support device for decorating fingernails or applying fluid on surfaces of fingernails

InactiveCN105686307AEasy to separateFlexible angle adjustmentManicure/pedicureBarrel ShapedBiomedical engineering

The invention discloses a support device for decorating fingernails or applying fluid on the surfaces of the fingernails, and belongs to the technical field. The support device comprises a barrel-shaped support main body which is composed of a finger support portion and a base portion; the finger support portion is located on the upper half portion of the support main body and is a semi-cylinder of which the lower portion is a plane and the upper portion is an arc-shaped surface, five finger separating grooves corresponding to the human fingers are uniformly distributed on the upper portion of the finger support portion, each finger separating groove has two through ends, the trend of the finger separating grooves is perpendicular to the axial direction of the support main body, the two inner sides of each finger separating groove are made of an elastic material, and finger separating blocks are formed on the separation portions among the finger separating grooves; the base portion is fixedly connected to the lower surface of the finger support portion and is a hard hemiprism of which the lower portion is provided with multiple support surfaces. According to the support device, the rollable base is arranged, the angles and positions of the fingers can be conveniently regulated, and the operation convenience and the hand comfort degree are greatly improved.

Owner:XUZHOU UNIV OF TECH

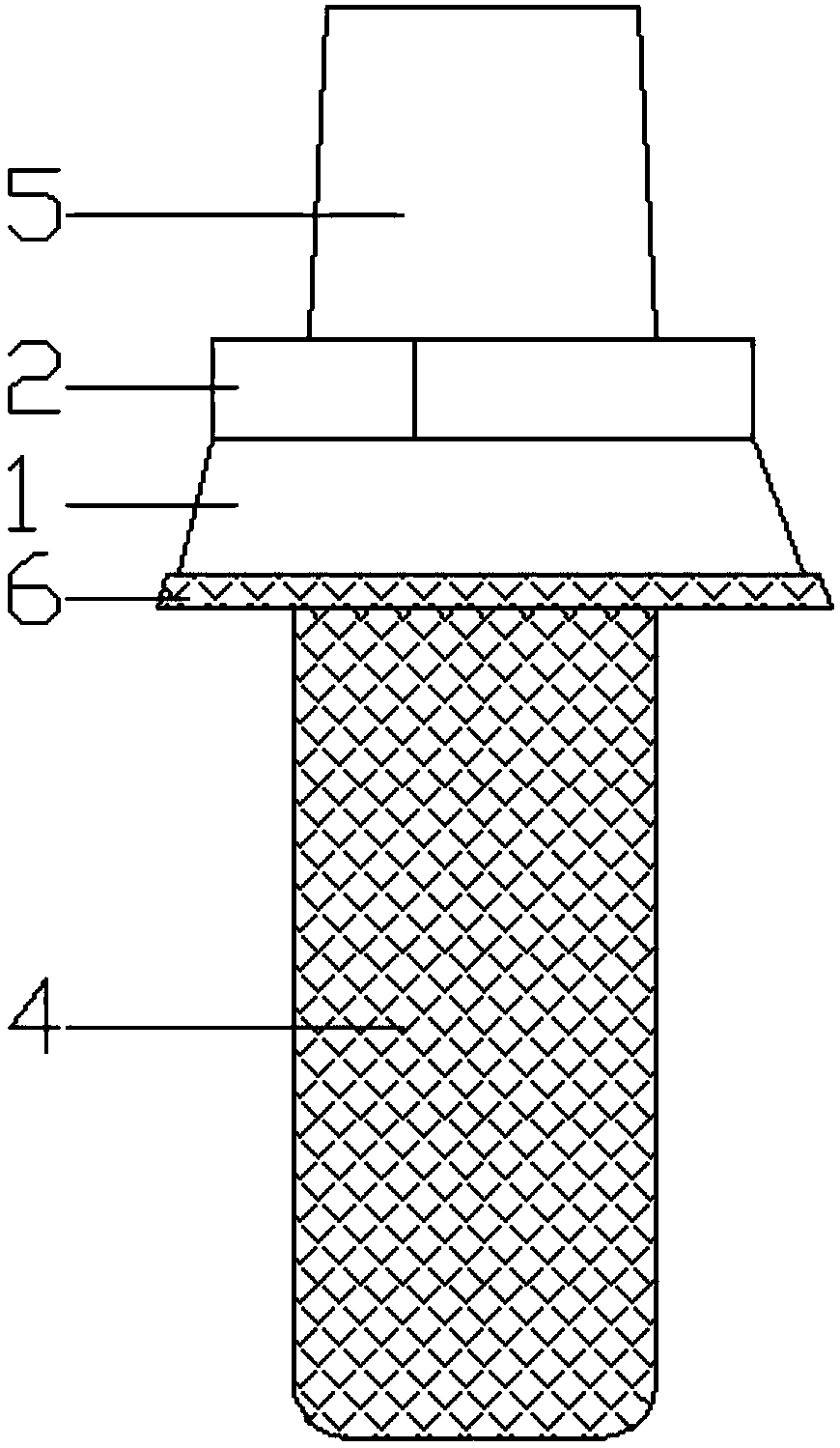

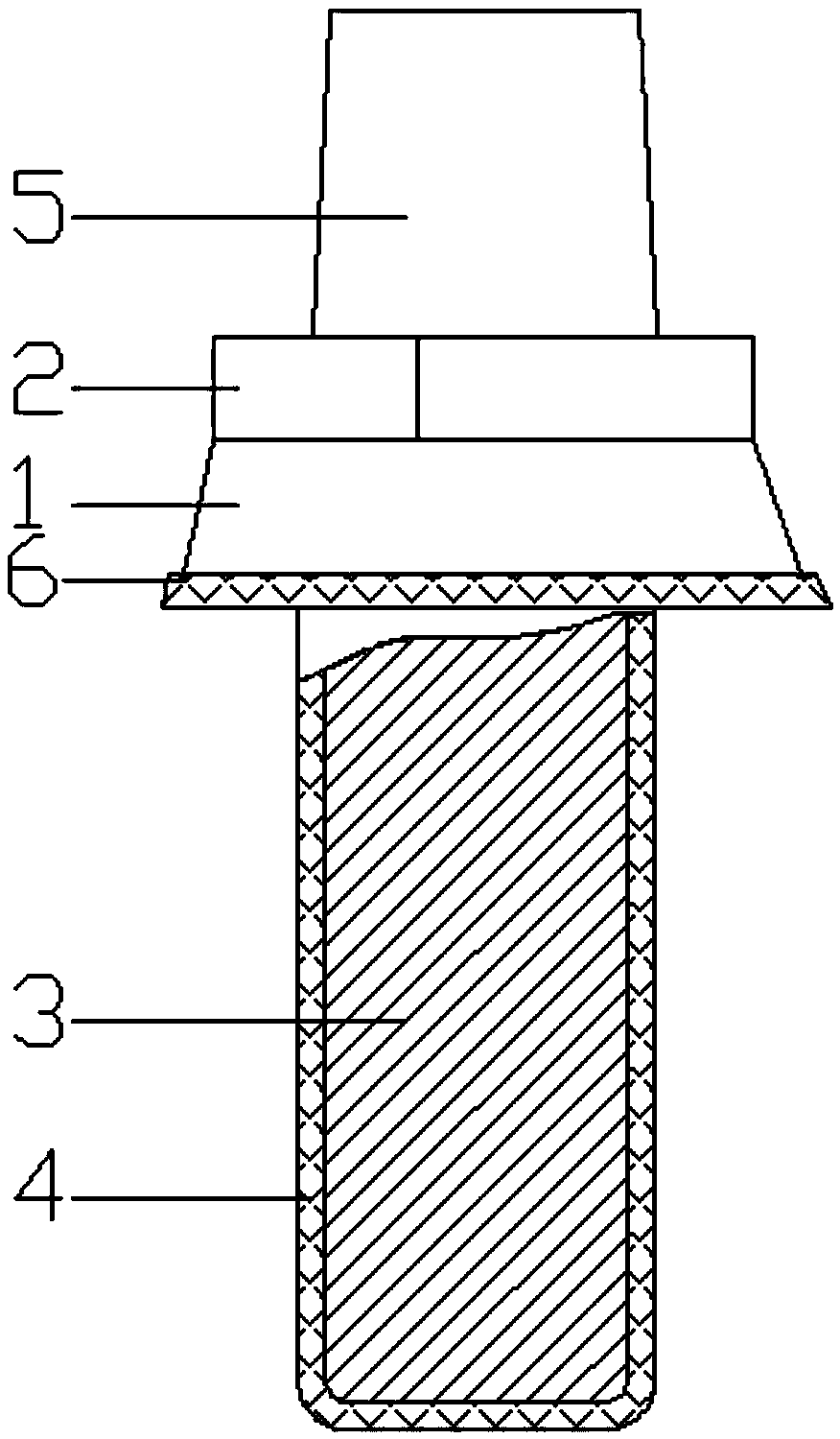

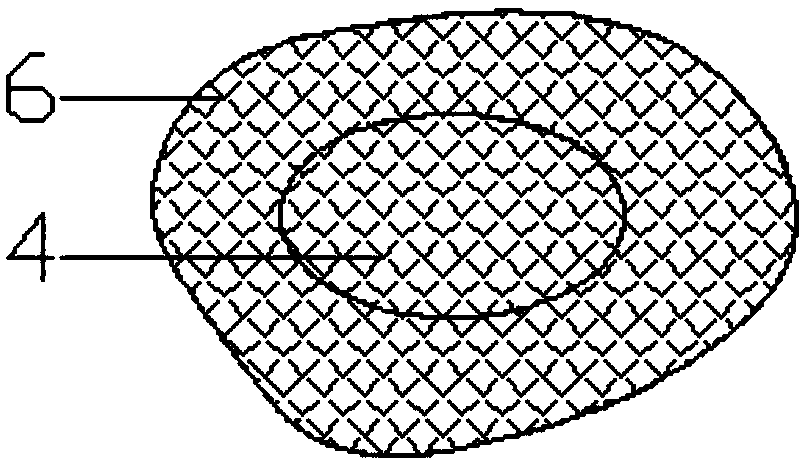

Distal tibial prosthesis

PendingCN109106476AConform to shapeIncrease contact areaJoint implantsKnee jointsBone marrow cavityBone growth

The present invention relate to a distal tibial prosthesis including a distal base and a distal handle, the distal handle comprises a bearing part and a bone trabecular structure layer A arranged on the outer surface of the bearing part, the upper end of the bearing part is connected with the bottom surface of the distal abutment, the top surface of the distal abutment is provided with an anti-rotation table, the top surface of the anti-rotation table is provided with an outer cone, the cross section of the distal handle is elliptical, and the outer surface of the bottom of the distal abutmentis provided with a bone trabecular structure layer B. As the distal handle of the invention is divided into a bearing weight part and a surface bone trabecular structure, the bearing weight part canmeet the load-bearing requirement and promote bone growth, thereby achieving medium-and long-term stability; the cross section of the distal stem is elliptical, which can increase the contact area between the distal tibial medullary cavity and the prosthesis surface, and also can prevent the prosthesis from rotating. It can achieve the initial stability without screw fixation, greatly shorten theoperation time and reduce the difficulty of operation. It can solve the problems of aseptic loosening, initial interface healing and periprosthetic fracture when the distal fixation length of cement tibial shaft prosthesis is insufficient.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

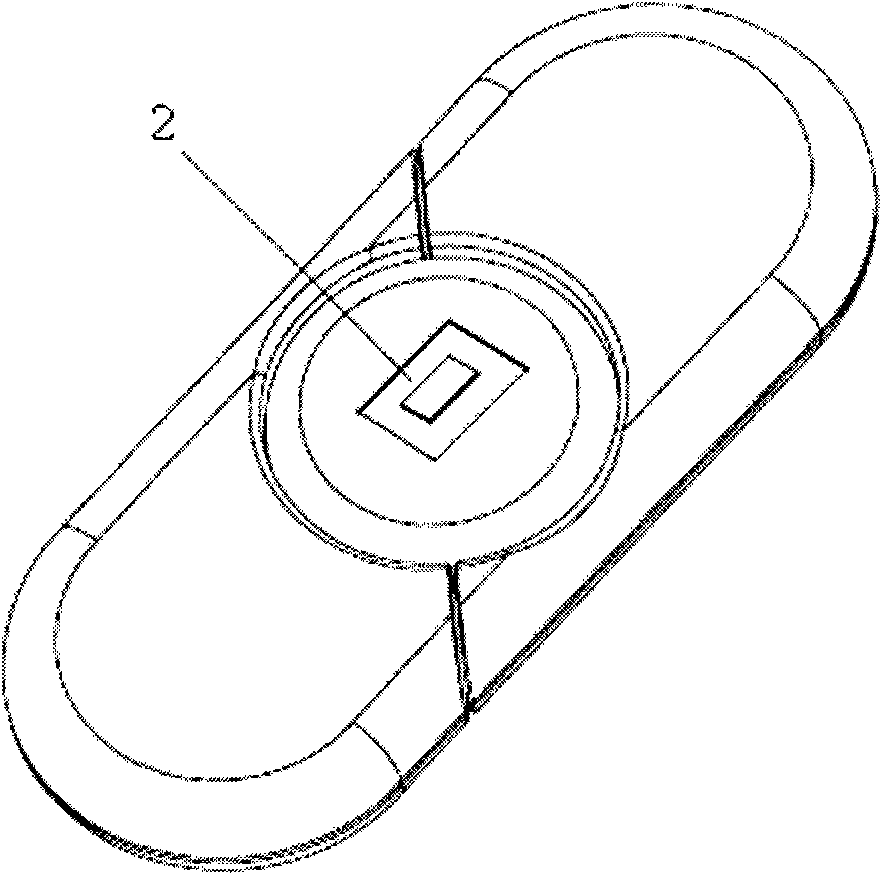

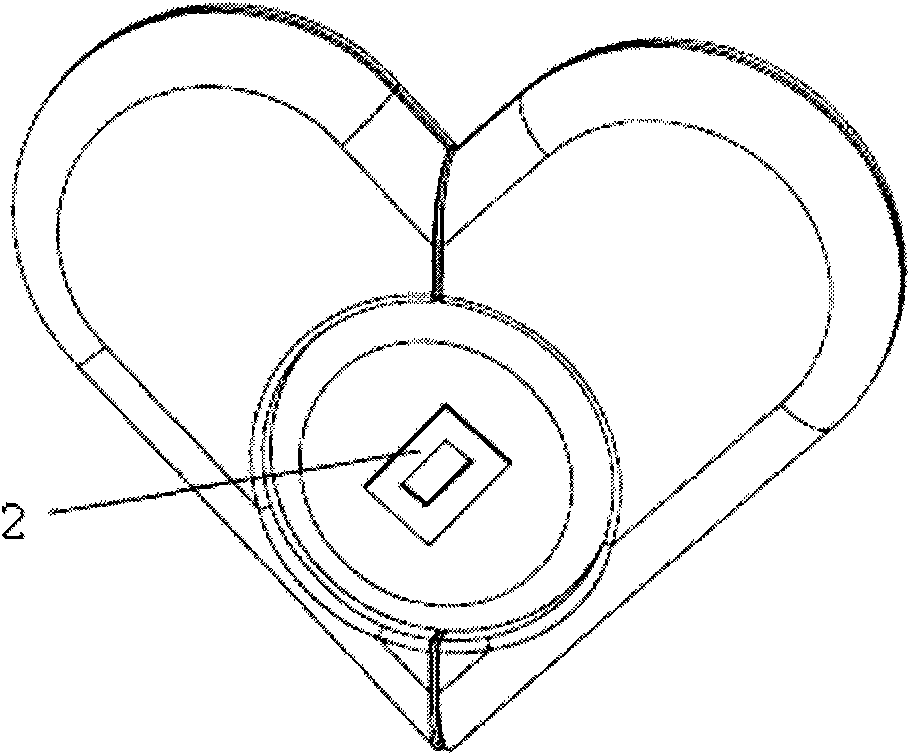

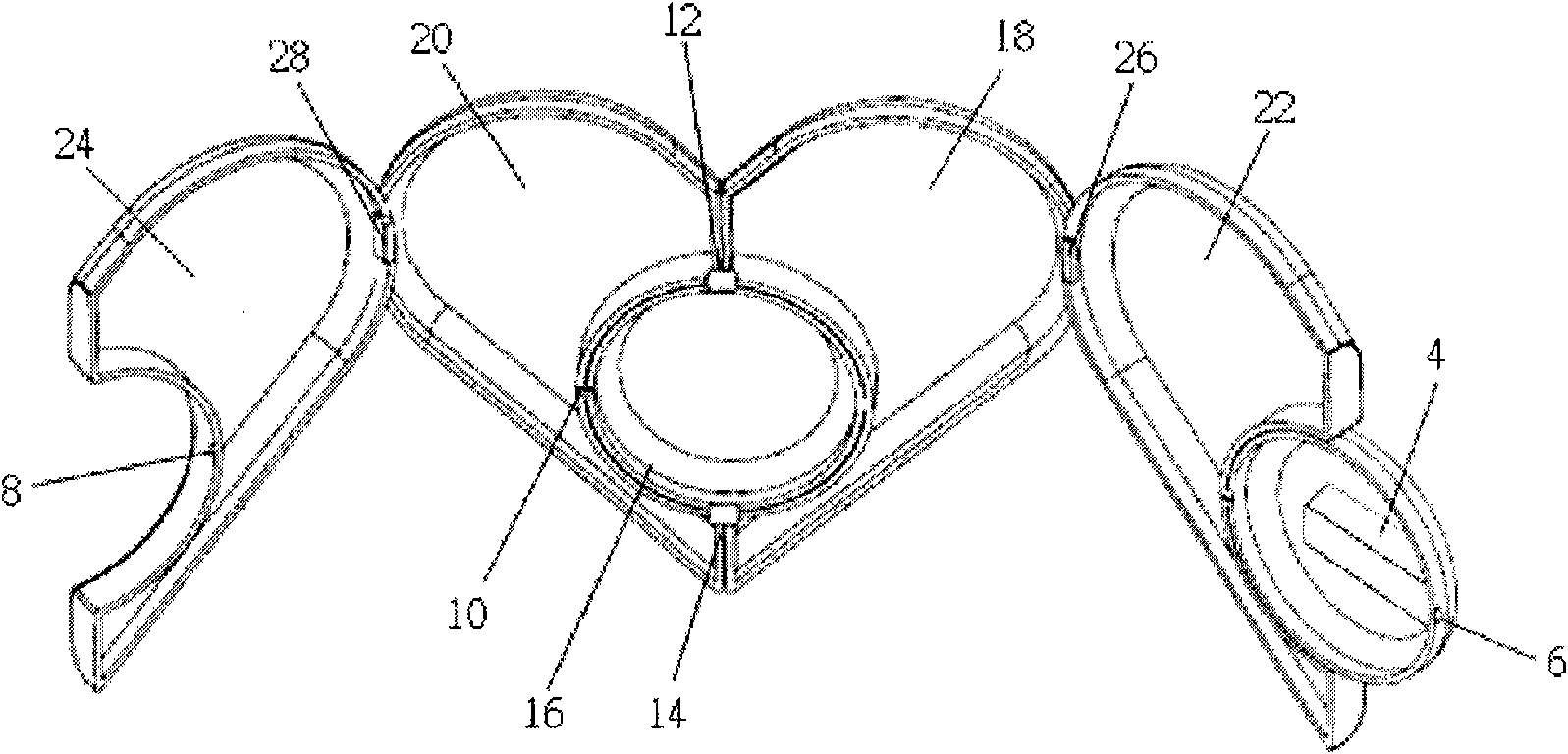

Heart-shaped structure in changeable shape

InactiveCN101646313AConform to shapeImprove securityDigital storageElectrical apparatus casings/cabinets/drawersLocking mechanismDisplay device

The invention discloses a heart-shaped structure in a changeable shape, which comprises a right base provided with an accommodating groove, a turnover left base which is pivoted with the accommodatinggroove of the right base, a right upper cover which is provided with a fingerprint identification device and a locking mechanism and is pivoted with the side of the right base, and a turnover left upper cover which is pivoted with the side of the left base. The inside of the right base can comprise a processing unit, a decoding unit, a digital-to-analog converter, a rechargeable battery and a storage unit, and a display is arranged in the groove. In addition, a shell of the right base can be provided with a built-in speaker, a sound output interface, a data input interface, a charging interface, a power supply switch and a control panel. The shape of the heart-shaped structure can be changed with the mood, and is easier to accept by male and female consumers.

Owner:WEISTECH TECH CO LTD

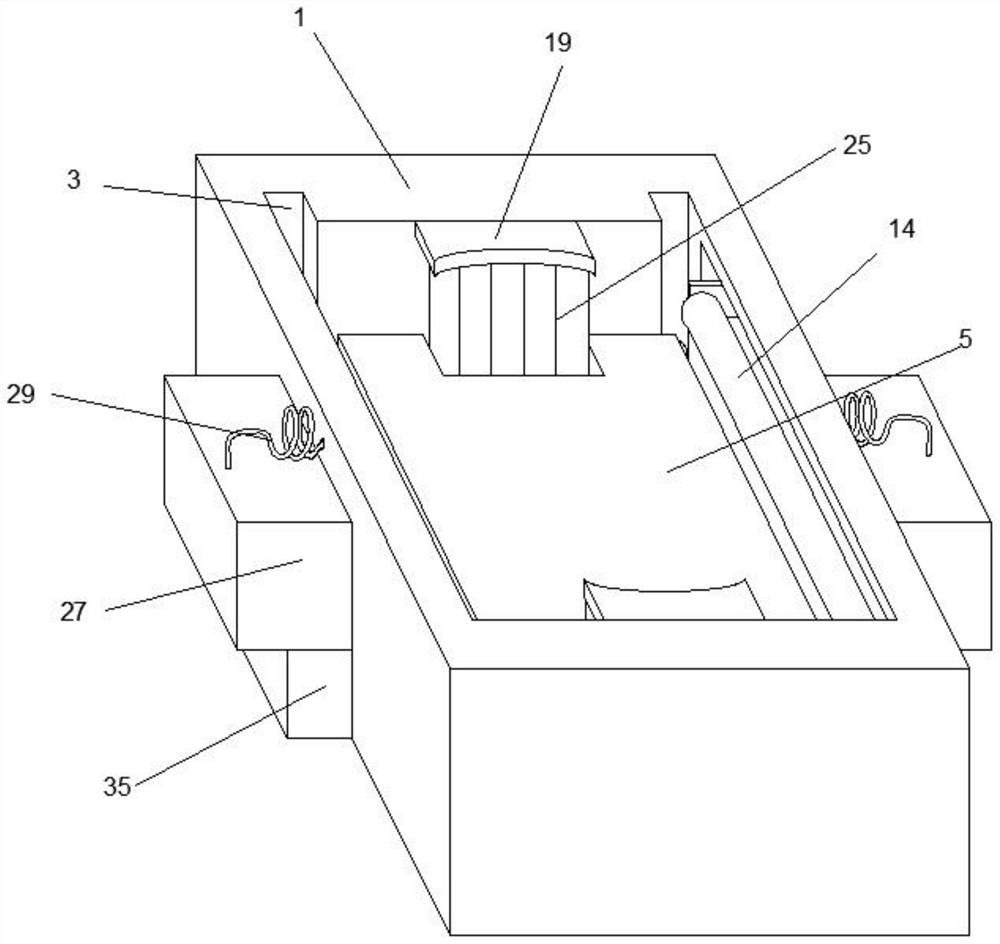

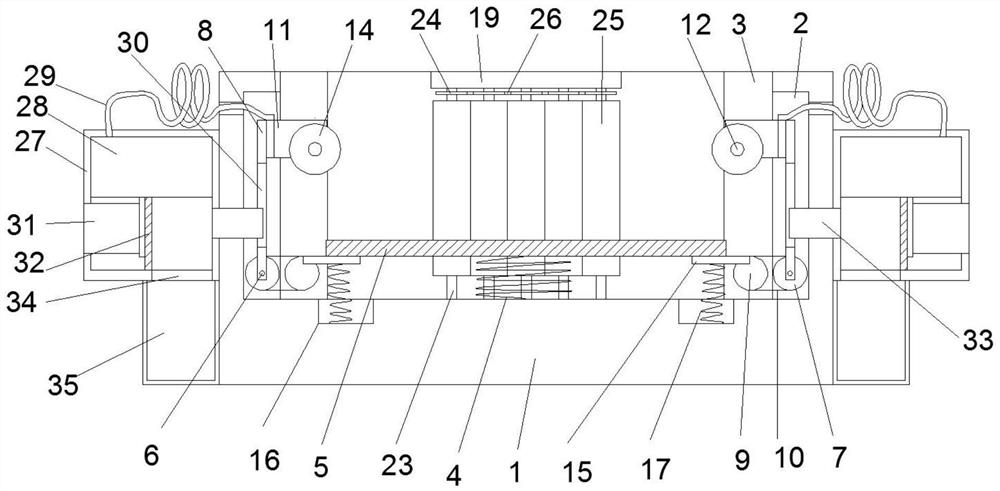

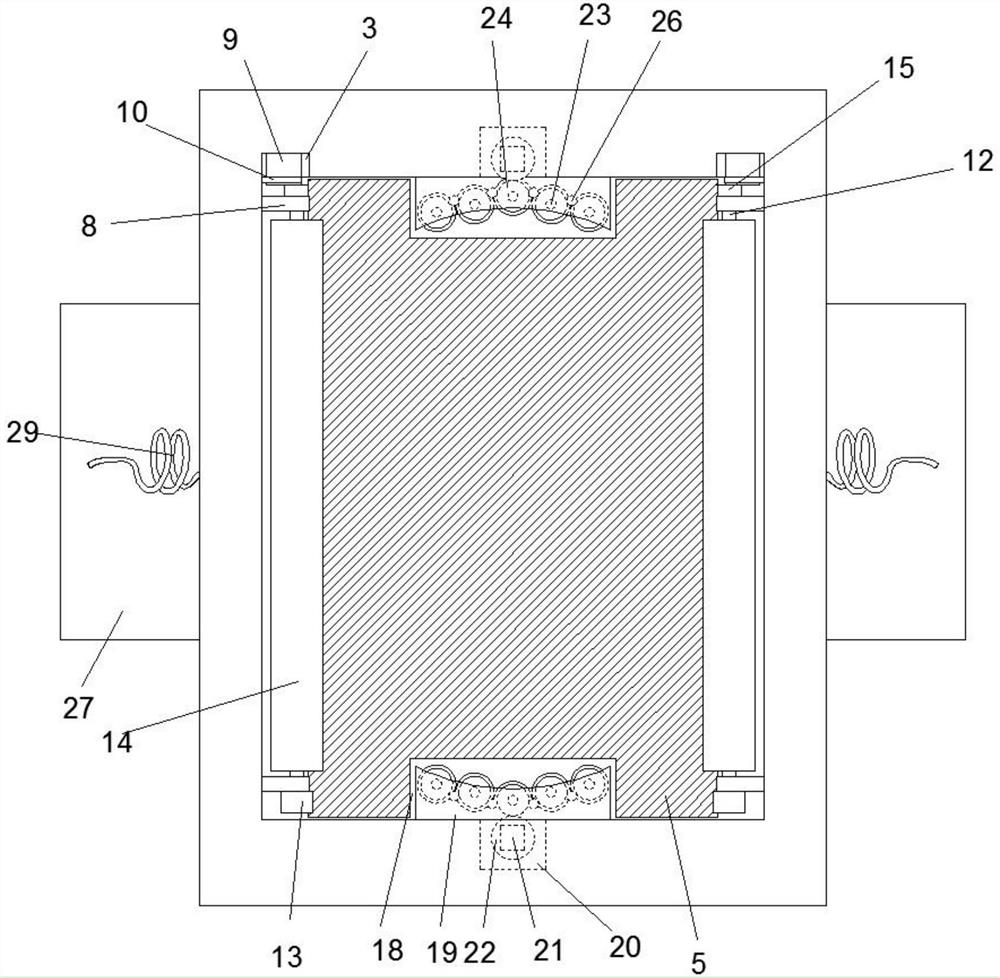

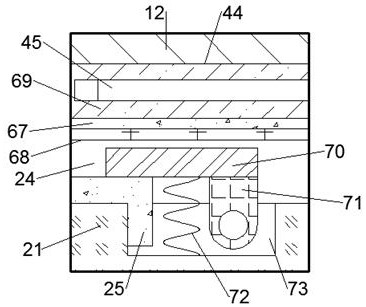

Full-automatic and efficient shoemaking polishing device

PendingCN114102382AFully automatic and efficient grindingEasy to polishGrinding carriagesShoemaking devicesGear wheelElectric machinery

The invention relates to the technical field of shoemaking, and discloses a full-automatic and efficient shoemaking polishing device which comprises a machine body, inner grooves are formed in the left side and the right side of the interior of the machine body, outer grooves are symmetrically formed in the rear surface of the interior of the machine body, the top ends of the outer grooves extend to the upper surface of the machine body, and first springs are fixed to the lower surface of the interior of the machine body; and a supporting plate is fixed to the top end of the first spring, a fixing shaft is rotationally connected to the lower portion of the interior of the inner groove, a first roller is fixed to the fixing shaft, and a rotating plate is fixed to the position, located in front of the first roller, of the outer surface of the fixing shaft. The first polishing rollers can relatively rotate to approach the shoes, the two sides and vamps of the shoes can be conveniently polished, the two sets of second polishing rollers arranged front and back are driven by the second motors and the gears to polish the front ends and the rear ends of the shoes, and the all-around polishing effect is achieved.

Owner:岳西县永润鞋业有限公司

Anti-slip wear-resisting plate for automobile foot mat

The invention discloses an anti-slip wear-resisting plate for an automobile foot mat. The anti-slip wear-resisting plate comprises a panel, wherein a foot structure is arranged on the panel; an anti-slip strip is arranged on the foot structure; a raised anti-slip mat is arranged at the center of the foot structure: a plurality of small bulges are arranged on the anti-slip mat. The anti-slip wear-resisting plate for the automobile foot mat has the beneficial effects that the foot structure arranged on the panel is fit for the shape of a human foot, so that the comfort level is increased; the anti-slip strip is arranged on the foot structure, so that an anti-slip function is achieved: the small bulges are arranged on the anti-slip mat, so that a massaging effect is achieved and the fatigue is relieved.

Owner:XIAN FORT NEW ENERGY TECH

Perforated cleaner for optical lenses

InactiveCN104384133AGood cleaning effectImprove stabilityCleaning using liquidsMotor shaftEngineering

The invention provides a perforated cleaner for optical lenses, which belongs to the field of optical lens processing equipment. The perforated cleaner comprises a cleaning barrel, wherein a carrying shaft and carrying plates are arranged in the cleaning barrel, posts are arranged between the two carrying plates, the external walls of the posts are provided with lens pits, each lens pit is shaped like a throat and is provided with a bottom hole at the center of the bottom of the lens pit, both ends of each lens are located on outer walls at both sides of the corresponding post, each lens pit is provided with a plurality of water holes which run through both sides of the corresponding post, one post is fixedly connected with a covering screen, the other end of the covering screen can surround the outer walls of all the posts and is fixed, the covering screen is provided with a plurality of round holes, a rotary motor is arranged on the upper end of the carrying shaft, the rotary motor shaft of the rotary motor is fixedly connected with the carrying shaft, a linear motor is fixedly connected with the motor housing of the rotary motor, the motor shaft of the linear motor is coaxial with the carrying shaft and is fixedly connected with the housing of the rotary motor, and the linear motor is fixed on a wall. The perforated cleaner has the advantages of great cleaning force, thorough cleaning and good cleaning effect.

Owner:中山市吉尔科研技术服务有限公司

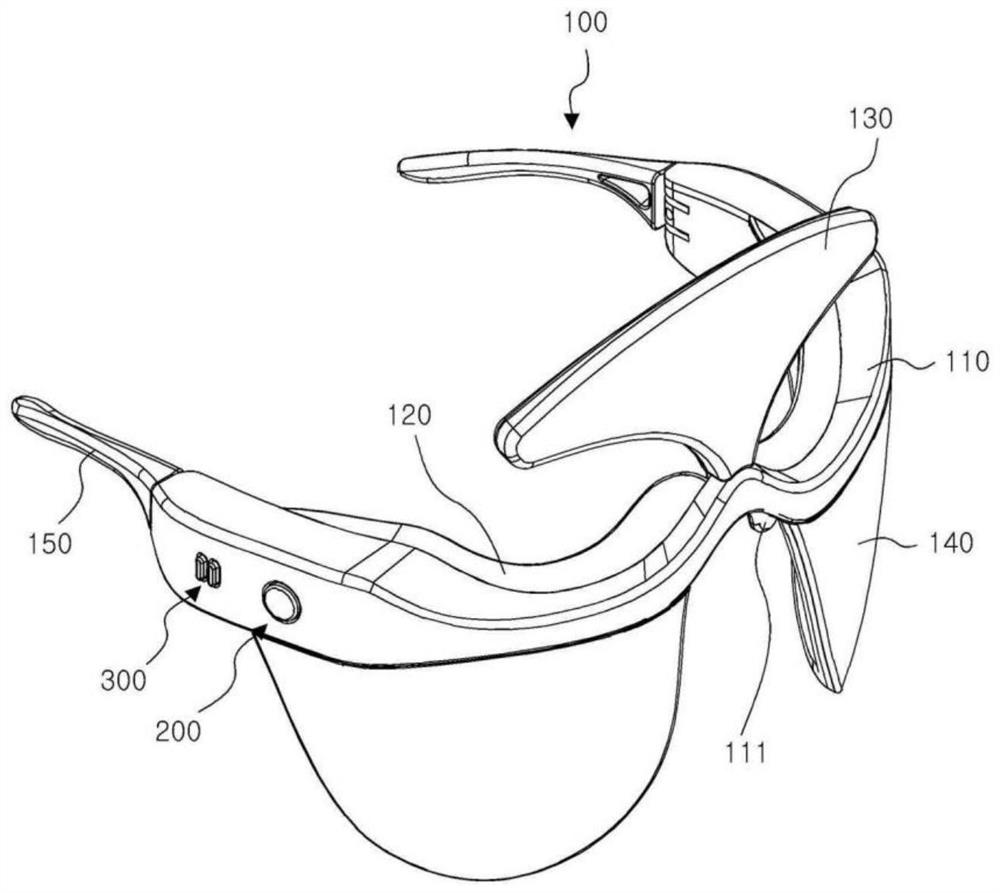

Touch All-in-One Skin Beauty Device for Personalized Facial Skin Care

ActiveCN111603678BEffective skin careGood skin conditionElectrotherapyDiagnostic recording/measuringFacial skinPhysical medicine and rehabilitation

The present invention relates to a contact-type all-in-one skin beauty instrument for personalized facial skin care, and more particularly, to a contact-type all-in-one skin beauty instrument for facial skin care, which is easy to separate, carry and store. It can be stored and can provide a personalized care plan that matches the user's skin characteristics.

Owner:革新伴 +1

Installation method of charging elastic pins of seat-type charger

InactiveCN106877029ASimple manufacturing processAchieve conductionVehicle connectorsBatteries circuit arrangementsEngineeringBattery charger

The invention discloses a method for installing charging pins of a seat-type charger, which comprises the following steps: opening a plurality of evenly arranged pin holes on the bottom of the charger housing, and the pin holes are connected with the charging pin holes of the charger housing. The charging slot is connected; turn the charging case over so that the bottom is facing up, and insert the charging pin through the lower end of the pin hole and make contact with the charging slot. After the pinholes are equipped with charging pins, place the circuit board horizontally on the end of the charging pins; use bolts to fix the circuit board to the bottom of the charger case. The seat-type charger of the present invention can realize the conduction between the charging pin and the circuit board without using welding or adding additional devices, and realizes the movable and elastic connection between the two, which simplifies the preparation process of the charger, and After the charging pin is damaged, the broken pin can be replaced separately, which saves resources.

Owner:CHENGDU RUIYI INFORMATION TECH

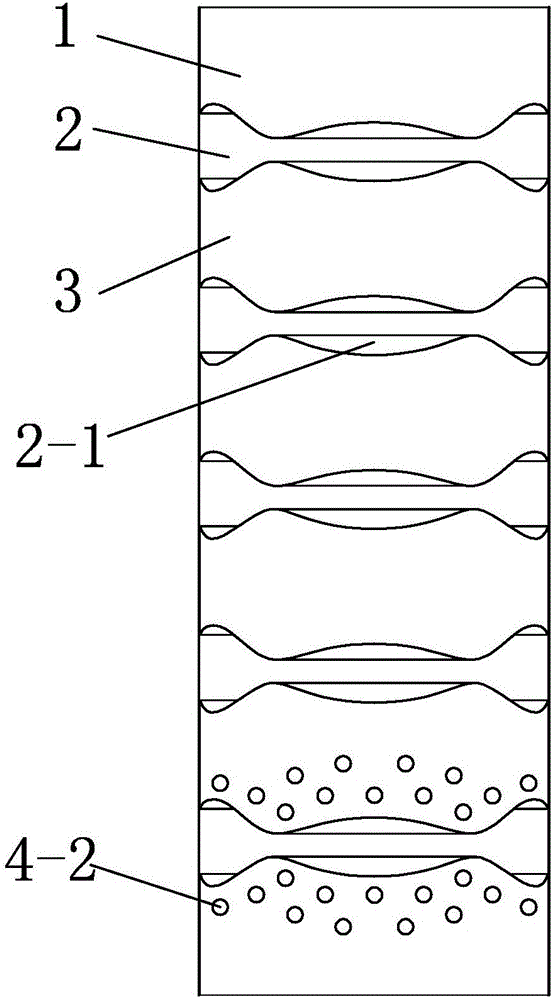

Automatic decontamination device for optical lenses

ActiveCN104384163AEasy to cleanConform to shapeFlexible article cleaningCleaning using liquidsEngineeringHigh pressure water

The invention provides an automatic decontamination device for optical lenses, belonging to the field of optical lens processing equipment. The automatic decontamination device comprises a box body which is internally provided with a plurality of lens plates; the lens plates are connected with the inner wall of the box body in a sliding way; lens grooves are respectively formed in the upper sides of the lens plates; the lens grooves are in necking down shapes from top to bottom, and the center of the bottom of each lens groove is provided with a bottom hole passing through the two sides of the corresponding lens plate; each lens groove is provided with a water through hole; each lens plate is also provided with a blow-down hole; the bottom of the box body under the lens plates is provided with a drain outlet; two spray head used for washing are respectively arranged on the inner walls of the two sides of the box body at the upper side and the lower side of each lens plate; the spraying directions of the spray heads are respectively towards the upper sides and the lower sides of the corresponding lens plates; the decontamination device also comprises liquid storage barrels; the spray heads arranged on the inner wall of one side of the box body are respectively communicated with one liquid storage barrel, and the spray heads are communicated with the liquid storage barrels respectively by a connecting pipe; each connecting pipe is provided with a high-pressure water pump. The automatic decontamination device is high in cleaning force, comprehensive in cleaning and good in cleaning effect.

Owner:南京蓝鼎光电技术有限公司

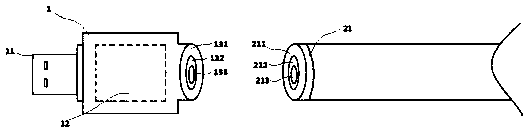

Magnetic type USB interface electronic cigarette charging device

InactiveCN107591868AConform to shapeVarious charging methodsBatteries circuit arrangementsTobacco devicesElectronic cigaretteUSB

The invention relates to a magnetic type USB interface electronic cigarette charging device. The charging device comprises a shell and a charging assembly, wherein the charging assembly is arranged ata front end of an electronic cigarette, a USB socket is arranged at one end of the shell, a magnet is fixedly connected to the other end of the shell, a charging circuit board is arranged in the shell and is electrically connected with the USB socket, and the charging circuit board and the magnet are electrically connected with a negative pole plate via a positive pole plate. A connection port ofan electrical appliance such as a computer can be accessed via the USB interface, or charging is performed by a mode of additionally arranging a charging head, the charging mode is versatile, the magnetic suction connection mode is firm, moreover, the connection part conforms to appearance of the electronic cigarette, and the whole device is more attractive.

Owner:惠州市泗创科技有限公司

An automatic decontamination device for optical lenses

ActiveCN104384163BEasy to cleanConform to shapeFlexible article cleaningCleaning using liquidsHigh pressure waterHigh pressure

The invention provides an automatic decontamination device for optical lenses, belonging to the field of optical lens processing equipment. The automatic decontamination device comprises a box body which is internally provided with a plurality of lens plates; the lens plates are connected with the inner wall of the box body in a sliding way; lens grooves are respectively formed in the upper sides of the lens plates; the lens grooves are in necking down shapes from top to bottom, and the center of the bottom of each lens groove is provided with a bottom hole passing through the two sides of the corresponding lens plate; each lens groove is provided with a water through hole; each lens plate is also provided with a blow-down hole; the bottom of the box body under the lens plates is provided with a drain outlet; two spray head used for washing are respectively arranged on the inner walls of the two sides of the box body at the upper side and the lower side of each lens plate; the spraying directions of the spray heads are respectively towards the upper sides and the lower sides of the corresponding lens plates; the decontamination device also comprises liquid storage barrels; the spray heads arranged on the inner wall of one side of the box body are respectively communicated with one liquid storage barrel, and the spray heads are communicated with the liquid storage barrels respectively by a connecting pipe; each connecting pipe is provided with a high-pressure water pump. The automatic decontamination device is high in cleaning force, comprehensive in cleaning and good in cleaning effect.

Owner:南京蓝鼎光电技术有限公司

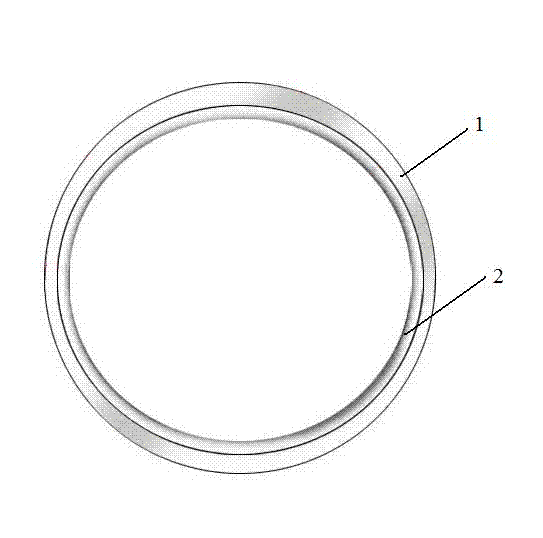

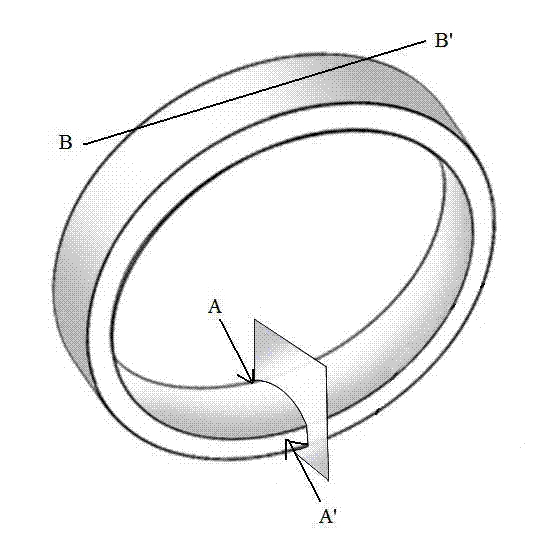

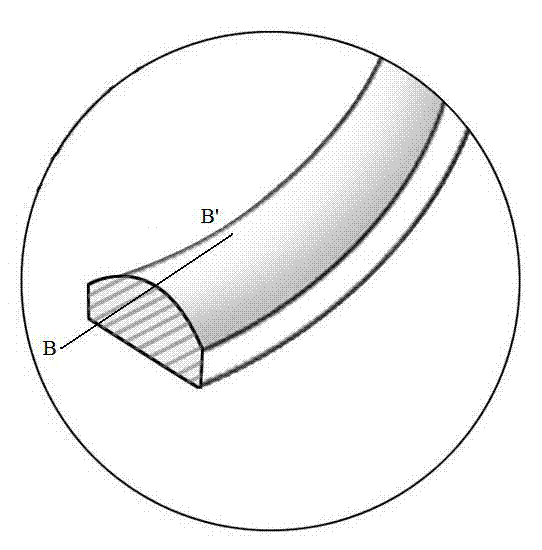

Ring with adjustable ring size

InactiveCN102763943ASolve the problem of not being able to put it in and not take it outAvoid pollutionFinger-ringsEllipseEngineering

The invention provides a ring with adjustable ring size, comprising an inner ring and an outer ring, wherein the surface of the inner ring is designed into a smooth convex arc; the section surface of the inner ring in the B-B' direction is designed into an ellipse, wherein the long axis and the short axis of the ellipse correspond to the longest ring size and the shortest ring size; and the B-B' direction is the section surface direction along the highest point of the convex arc vertical to the A-A' direction of the tangent of the inner ring. With the adoption of the ring, a consumer can adjust the ring size by rotating the ring according to the shape and the thickness of a finger without booking or correcting the ring size especially, in this way, the environment pollution caused by electroplating in the ring size correcting process is avoided.

Owner:上海金伯利钻石首饰有限公司 +1

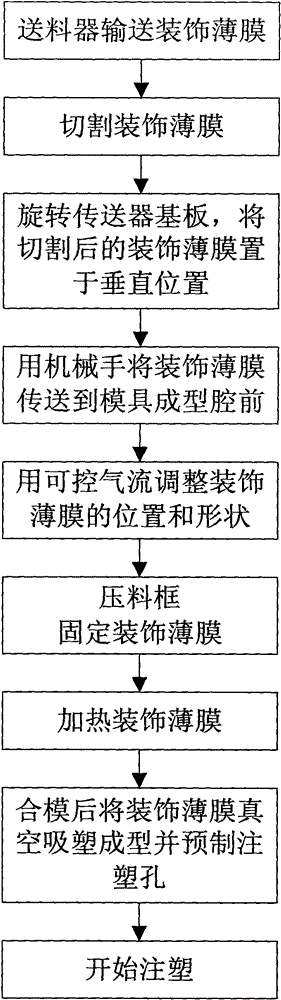

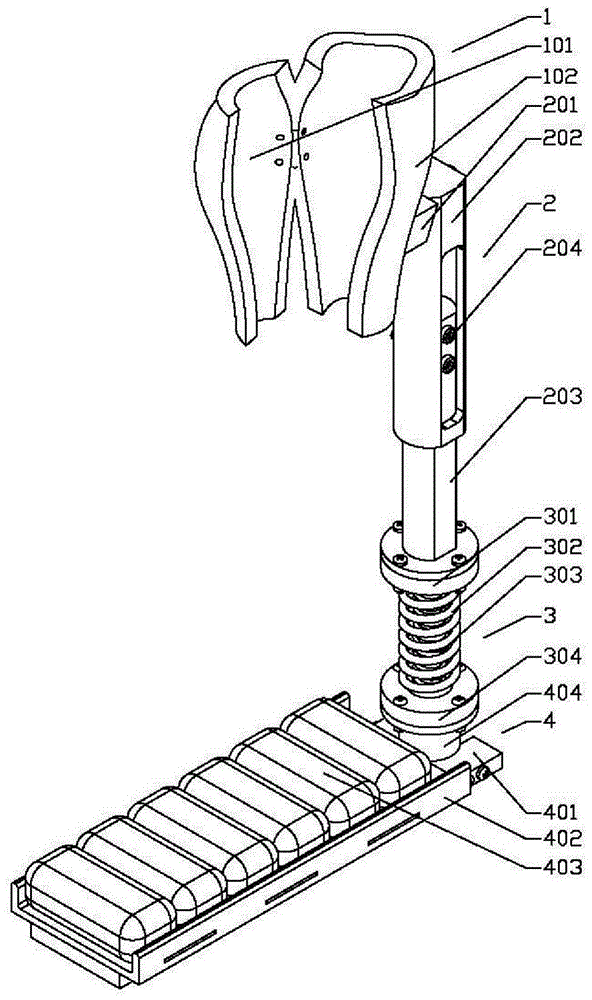

Shape self-adaptive in-mold decorating method

The invention relates to a shape self-adaptive in-mold decorating method, which comprises the following production steps: 1, conveying a decorating film by a material conveyer; 2, cutting the decorating film; 3, rotating a base plate of a conveyer, and placing the cut decorating film in a vertical position; 4, using a mechanical hand for conveying the decorating film to a position in front of a forming cavity of a mold; 5, using a controllable air flow for regulating the position and the shape of the decorating film; 6, using a material pressing frame for fixing the decorating film; 7, heating the film; 8, carrying out vacuum injection suction forming on the decorating film after the mold assembly, and prefabricating injection molding holes; and 9, controlling an injection molding machine and peripheral equipment to start injection molding, if required after the third step, rotating the cut decorating film for 90 degrees for changing the printing direction of patterns of the decorating film. The decorating film comprises a transfer printing film and an in-mold transfer printing film. The invention has the advantages that the film does not need to be preprocessed and pretreated in advance, products or parts with surface decoration in any shape can be produced only through one work procedure, the production cost is low, and the popularization is easy.

Owner:欧阳雷 +1

Adjustable weight-bearing functional brace for tibial fractures

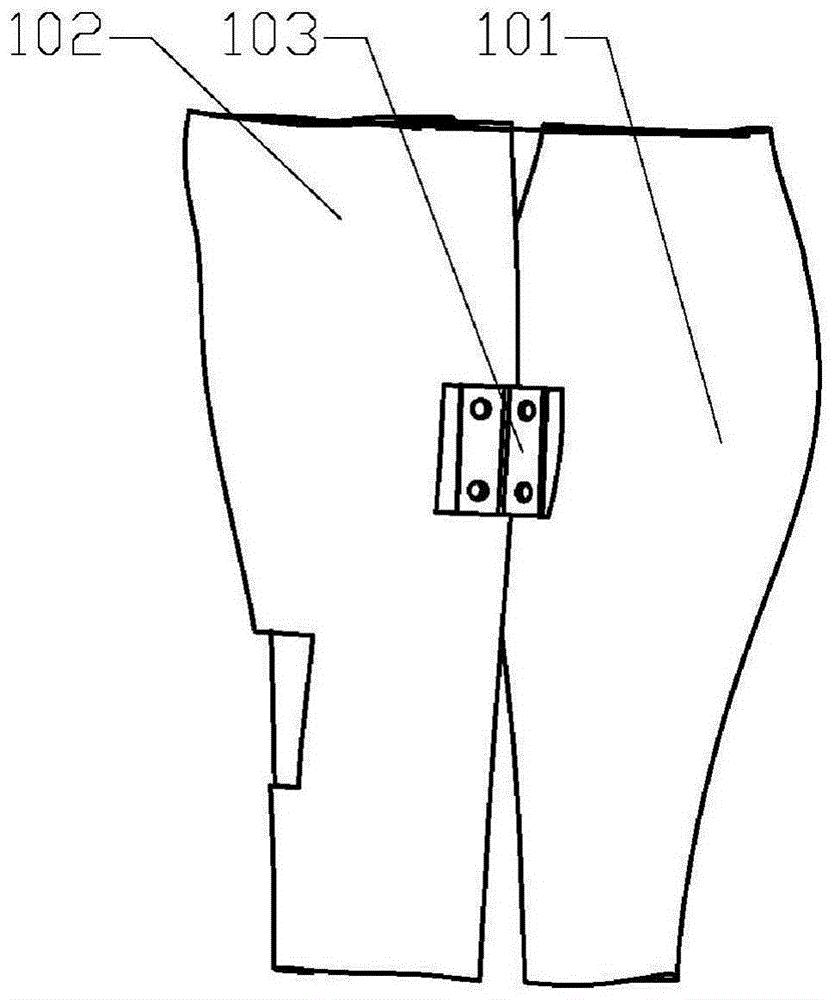

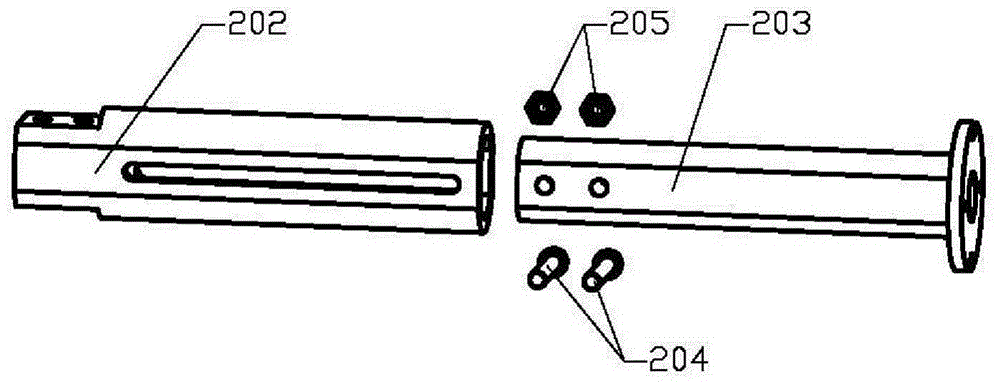

The invention discloses a tibial fracture adjustable-weight functional brace, comprising a receiving chamber, a height adjusting module, a spring bearing module and a footplate module. The receiving chamber is attached to the upper portion of a shank. The receiving chamber is fixedly connected with the height adjusting module through a receiving chamber connector. The height adjusting module and the spring bearing module are coaxial. The lower portion of the height adjusting module is fixedly connected with a spring upper end plate. The spring bearing module is fixedly connected with the footplate module through the spring lower end plate and a bottom plate holder. The footplate module comprises a bearing balloon used for supporting a human foot. The brace is worn on a diseased limb through an elastic bandage. The brace can replace the fractured limb to share body weight during a tibial fracture rehabilitation phase, the shared weight is adjustable during the rehabilitation phase, fracture end faces are therefore stimulated, and actual facture healing is accelerated. The brace allows the patient to freely walk and do functional training without a crutch or a wheelchair.

Owner:SOUTHEAST UNIV

An intelligent disinfectant with face recognition function for washing mobile phones

ActiveCN112741520BEasy to installEasy to useHolders and dispensersCharacter and pattern recognitionSimulationHand sanitizer

The invention relates to an intelligent disinfectant mobile phone with a face recognition function, which includes a main body and a limiting groove. A fastening cover is arranged in the middle of the top of the main body, and a smoke alarm is installed on the upper end of the outer fastening cover. An electric slide rail is arranged outside the rear end of the main body, and a mounting plate is installed at the end of the electric slide rail, and a camera is arranged in the middle part inside the front end of the main body, and an outer cover is installed outside the camera head. The beneficial effects of the present invention are: the smart disinfectant with face recognition function for washing mobile phones, through the setting of electric slide rails, after the installation of electric slide rails, the entire mobile phone can be washed according to the user's height along the electric The horizontal and vertical directions of the slide rails move up and down to prevent users from bending over or stepping on their feet to take the hand sanitizer when washing their phones, and the installation of the electric slide rails is convenient for users to install and use, effectively reducing the need for hand washing. Limitations in the use process, improve the effect of convenient use.

Owner:RCSTARS IND SHENZHEN CO LTD

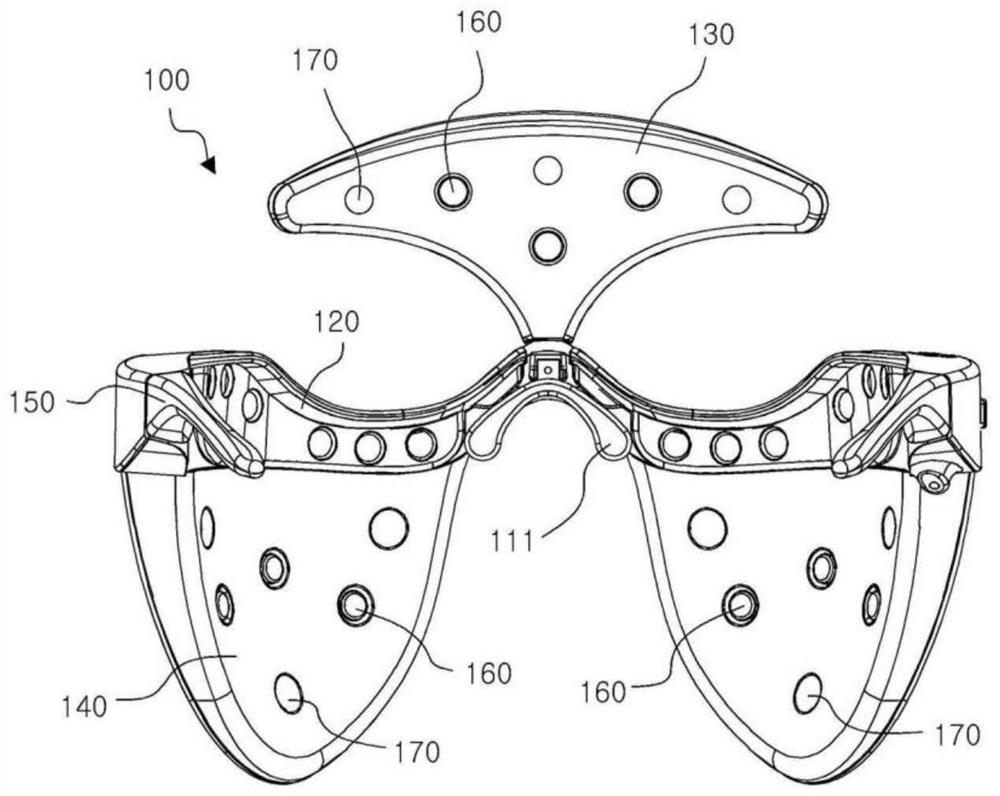

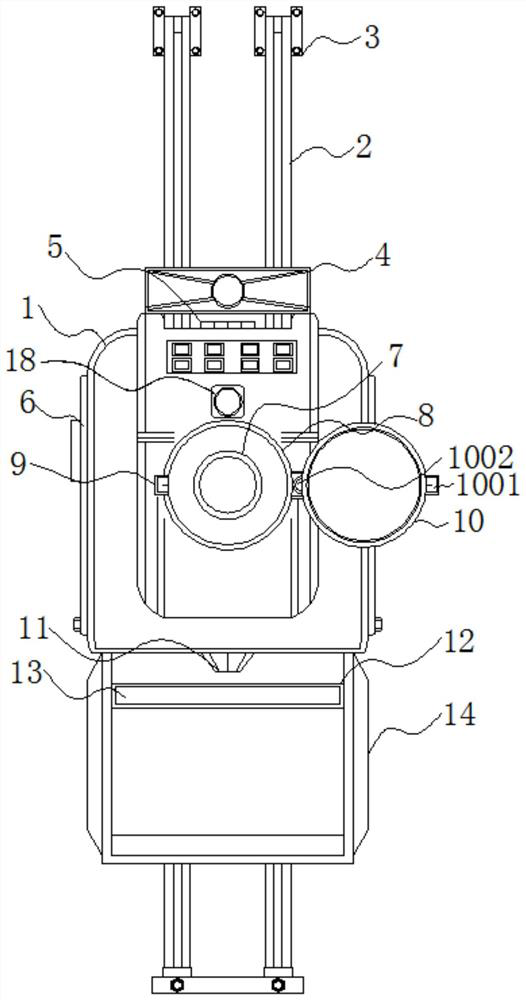

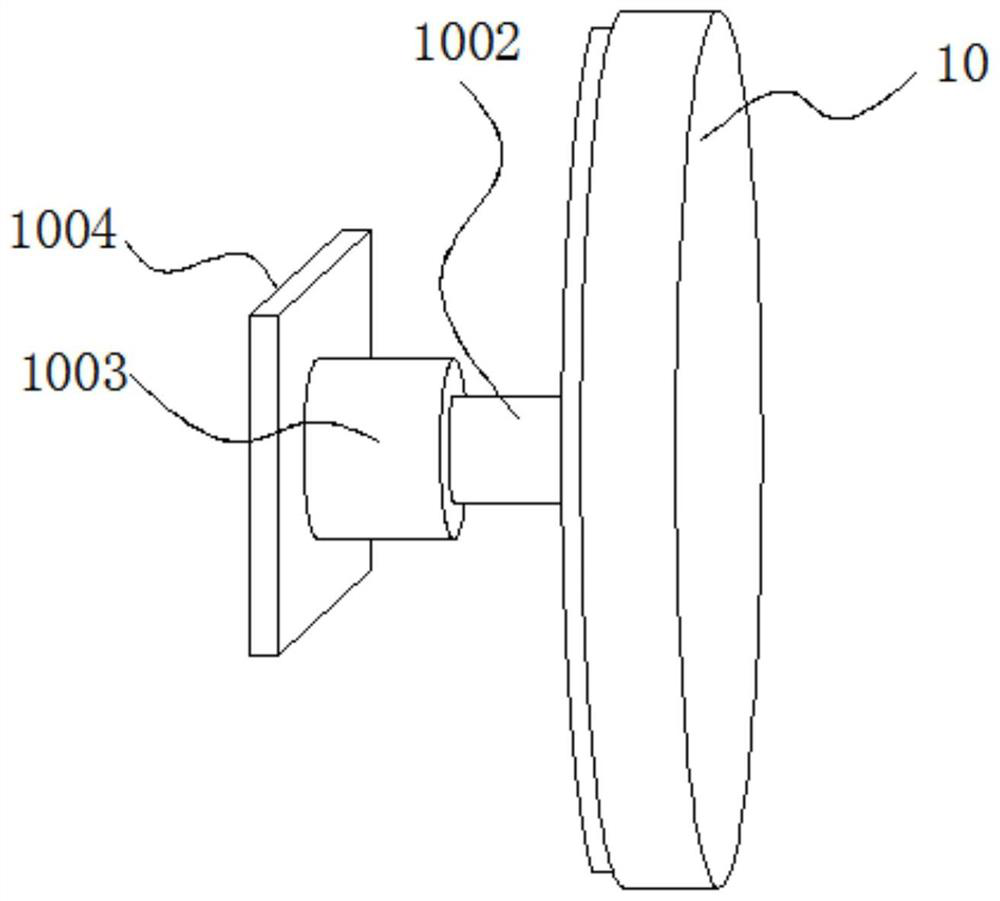

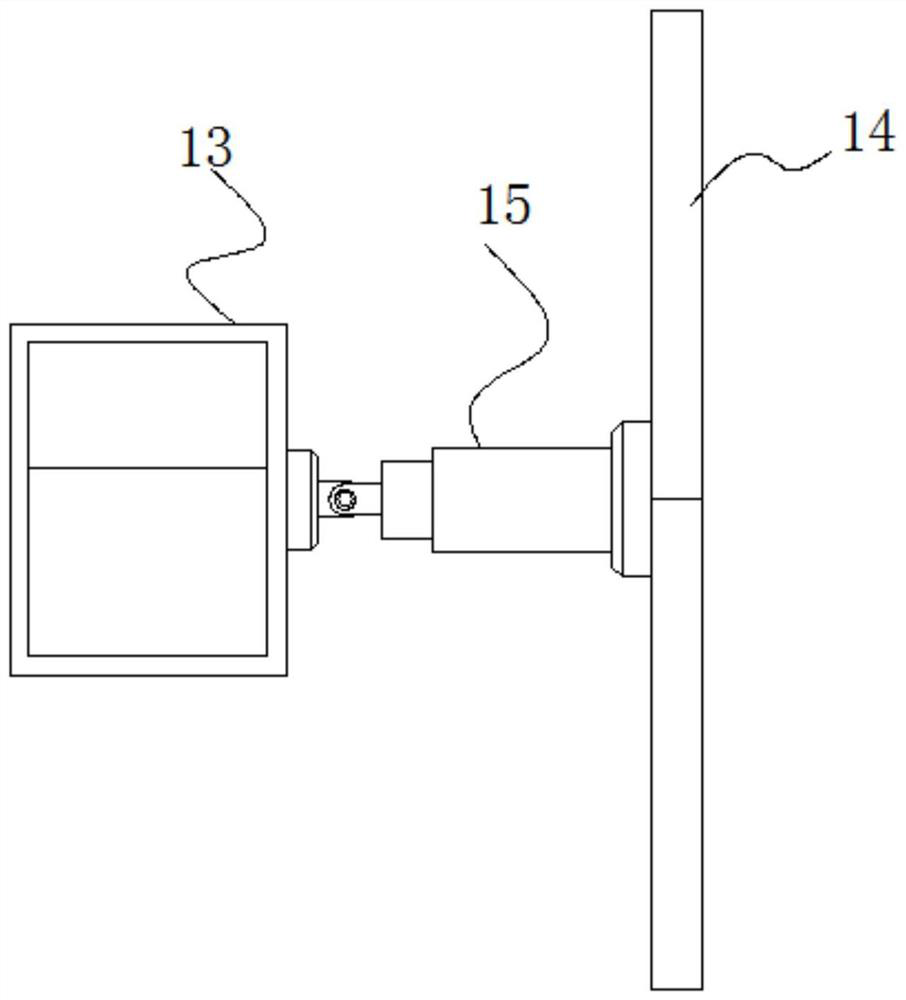

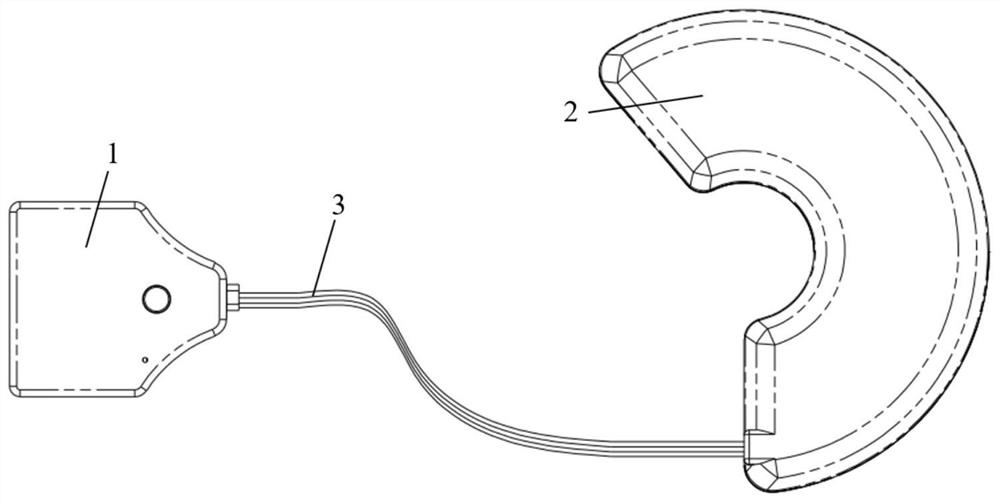

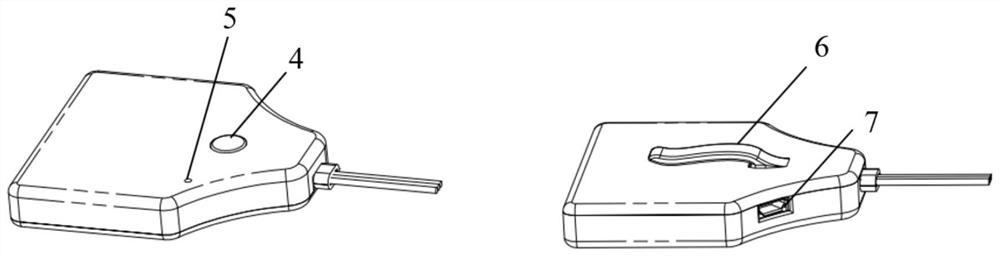

Graphene far infrared mammary gland therapeutic apparatus

PendingCN112999521ANo allergy riskConform to shapeLight therapyHeating element materialsHuman bodyGraphene

The invention relates to a graphene far infrared mammary gland therapeutic apparatus, the therapeutic apparatus comprises a controller, a connecting wire and a therapeutic head, the controller and the therapeutic head are connected through the connecting wire, the controller can be detachably fixed at the heart of a bra, and the therapeutic head comprises a protective film, a filler, a heating element and an optional adhesive layer. The shape of the therapeutic head of the infrared mammary gland therapeutic apparatus accords with the mammary gland shape of a human body, wearing is convenient, and the same style can support different individuals to use.

Owner:CHENGDU GRAPHENE APPL INST FOR IND TECH CO LTD

A special bed for pregnant women used for prenatal diagnosis

ActiveCN107951660BEasy to operateSuitable for placementOperating tablesDiagnosticsSpecial bedHydraulic cylinder

The invention relates to a special prenatal diagnosis bed for a pregnant woman. The special prenatal diagnosis bed includes a counterweight base, a rotating motor and pregnant belly holding devices; the counterweight base is arranged on the body of the special bed; the rotating motor is fixed to the upper end of the counterweight base by bolts; a supporting lifting column is arranged at the upperend of the rotating motor in a transmission mode; a connecting supporting rod is movably installed on the side wall of the supporting lifting column; a bottom supporting platform is fixedly arranged at the end of the connecting supporting rod; the pregnant belly holding devices are symmetrically arranged on the side walls of the two ends of a backrest; display screen lifting hydraulic cylinders are symmetrically arranged on and rotatably connected to the side wall of the backrest; a leisure display screen is movably fixed to the upper ends of the display screen lifting hydraulic cylinders. Thespecial prenatal diagnosis bed for the pregnant woman is provided with leg support plates which are of arc-shaped groove structures, and the length of each leg support plate is 50 centimeters. The leg support plates fit the curved structures of the human legs, are in line with ergonomics and make the legs more comfortable during placement, and the length fits the majority's placement.

Owner:梁山县人民医院

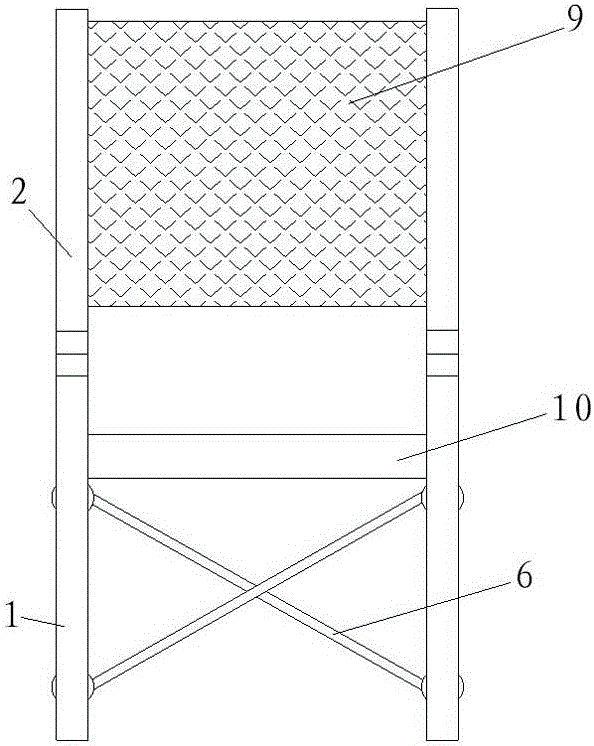

Comfortable commode chair

The invention discloses a comfortable commode chair. The comfortable commode chair comprises two parallel support components on the seat frame side, a back cushion, a cross pipe component and a seat cushion component, wherein the back cushion, the cross pipe component and the seat cushion component are arranged between the two parallel support components on the seat frame side. Each support component on the seat frame side comprises a front support rod and a back support rod which are parallel to each other, and an upper supporting rod, a middle supporting rod and a lower supporting rod which are parallel to one another are arranged between the front support rod and the back support rod. The cross pipe component comprises two cross rods, an upper transverse rod and a lower transverse rod which are parallel to each other are connected to two ends of each cross rod respectively, each upper transverse rod is arranged between the corresponding front support rod and the corresponding back support rod and is parallel to the corresponding upper supporting rod, and each lower transverse rod sleeves the corresponding lower supporting rod and is rotatably connected with the same. The back cushion is arranged between the two back support rods, the seat cushion component is arranged on the upper transverse rods, an arc section is arranged on an upper section of each back support rod, fixing pull ropes connected end to end are arranged on each arc section, and a backrest rod is arranged at the top end of each back support rod. The comfortable commode chair has the advantages of novel and reasonable structural design and capability of overcoming the defects in the prior art.

Owner:江阴市新盛医疗器材设备有限公司

Processing machine for printing and dyeing full patterns on T-shirts

ActiveCN112571936AGood aestheticsGood efficiencyRotary pressesPrinting press partsDyeingManufacturing engineering

The invention discloses a processing machine for printing and dyeing full patterns on T-shirts. The processing machine comprises a printing and dyeing machine body and a loading machine body, whereina rotating cavity with an upward opening is formed in the loading machine body, opening and closing shafts are fixedly arranged on the front side face and the rear side face of the printing and dyeingmachine body correspondingly and are rotatably connected with the front wall and the rear wall of the rotating cavity, a torsional spring is fixedly installed between the printing and dyeing machinebody and the rotating cavity, and a loading cavity with an upward opening is formed in the loading machine body. By means of the processing machine, elastic arc printing and dyeing can be conducted onthe surface of a T-shirt, so that when the T-shirt is worn on a human body, patterns better conform to the appearance of the human body and cannot deform, and the attractiveness is better. After theT-shirt is loaded and a loading column is pressed into the loading cavity, the T-shirt can be directly positioned and tightened through transmission control, the efficiency is higher, manual operationis not needed, and the intelligent level is higher. Besides, in the printing and dyeing process, a soft elastic block performs upward jacking through transmission control, then the T-shirt forms a tensioned cambered surface, and therefore the printing and dyeing effect is better.

Owner:莆田晟辉体育用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com