Cable cut-off tool

A technology for cutting knives and cables, which is applied to shearing devices, knives for shearing machine devices, metal processing equipment, etc., and can solve problems such as inconvenient use, unreasonable structure of cable cutting knives, and poor cutting effect. Achieve the effect of convenient operation, improved cutting effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

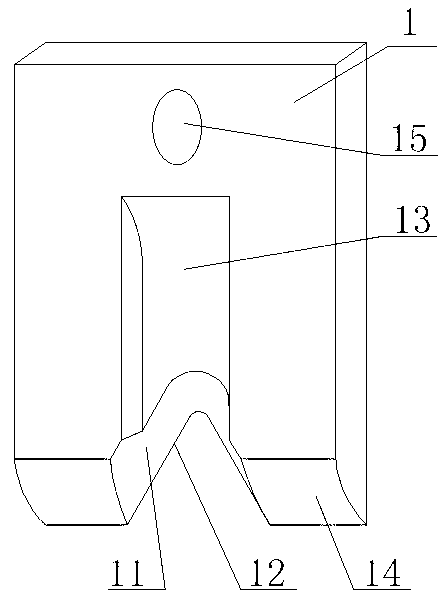

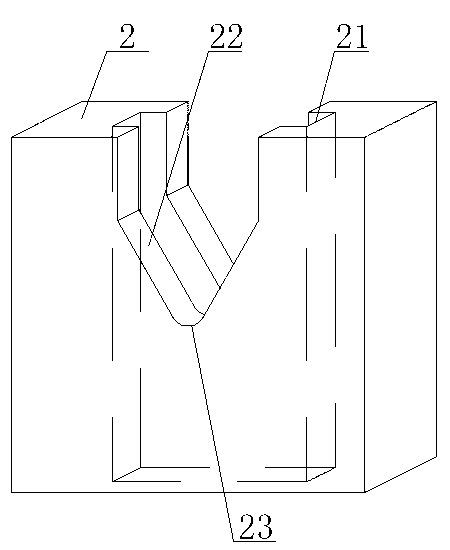

[0034] Such as figure 1 and figure 2 As shown, the cable cutting knife is mainly composed of a blade 1 and a combined knife seat 2 that cooperate with each other, wherein the blade 1 and the combined knife seat 2 are all made of hard alloy, which improves the service life of the present invention, and utilizes The unique structural design and high-precision matching relationship of the present invention have greatly improved the problem that the existing cable cutting tools do not cut cleanly on special cables such as cables with Kevlar protective layers, and there are a lot of fiber residues. In the manufacturing process of the present invention, the accuracy of the blade 1 and the combined tool holder 2 itself is controlled within 5 microns (ie 0.005 mm) by using special and precise techniques, and the matching accuracy of the two is controlled within 2 microns (ie 0.02 mm). within mm). The unique structural design of the present invention is described in detail below.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com