Comb-shaped holding frame formed by plastic and manufacturing method thereof

A cage, comb-like technology, applied in the direction of bearing bushes, other household appliances, bearings of rotary motion, etc., can solve the problem of expensive and expensive processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

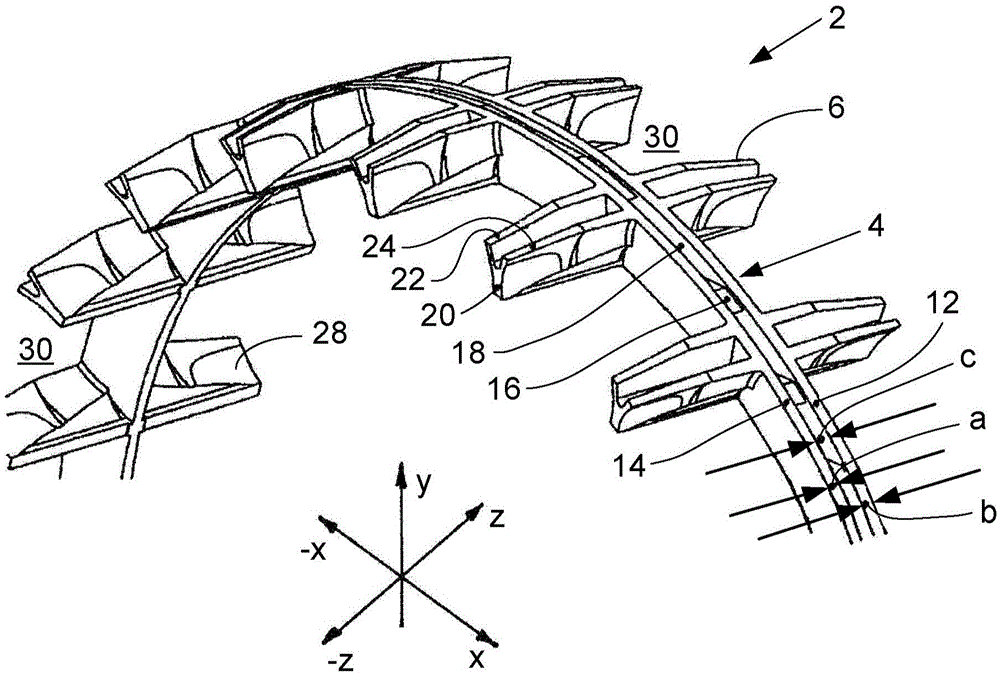

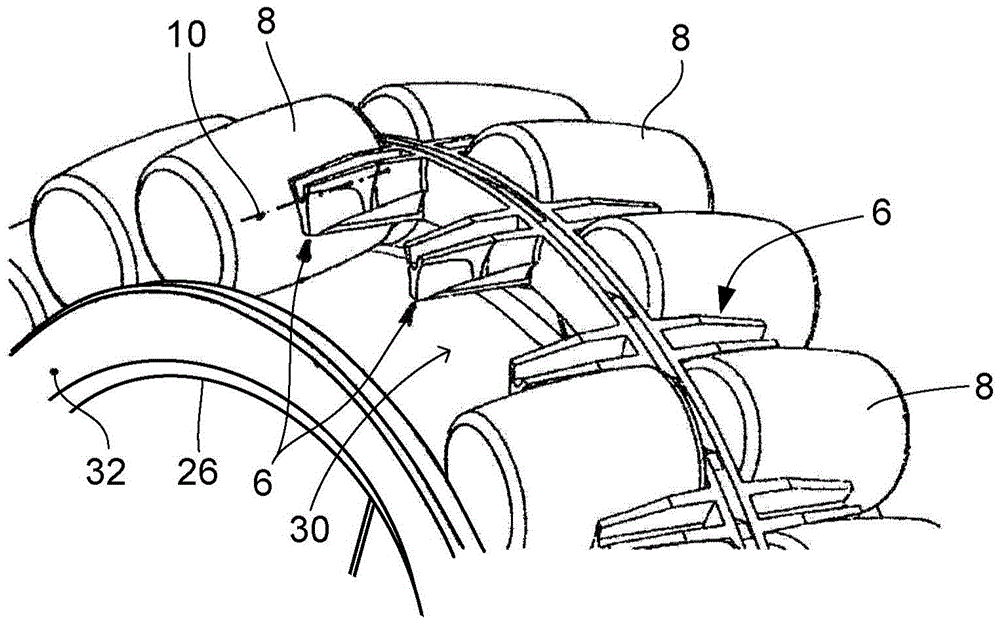

[0018] exist figure 1 The comb-shaped cage 2 shown in is configured as a double-comb-shaped cage, and basically consists of a cage ring 4 and a certain number of cage rings 2 scattered in the circumferential direction, axially from the cage ring 4 These beams hold and guide the associated rolling elements 8 configured as bearing rollers substantially along the axial generatrices 10 of the rolling elements 8 .

[0019] exist figure 1 In the embodiment shown in , the cage ring 4 consists of two annular disks 12 , 14 arranged coaxially with one another, which are integrally connected to one another by means of a plurality of spacers 16 arranged distributedly in the circumferential direction of the annular disks . as from figure 1 It can be seen that the two annular disks 12, 14 have the same wall thickness a or b and that the axial distance c between the two annular disks 12, 14 is also substantially the same as the wall thickness a or b, so that The spacer 16 also has the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com