Device for cleaning optical lenses in batches

A technology for cleaning optical lenses and batches, which is applied to cleaning methods using liquids, cleaning flexible objects, cleaning methods and utensils, etc. It can solve the problems of long cleaning time, poor cleaning effect, and high cleaning force, and achieves a clever structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

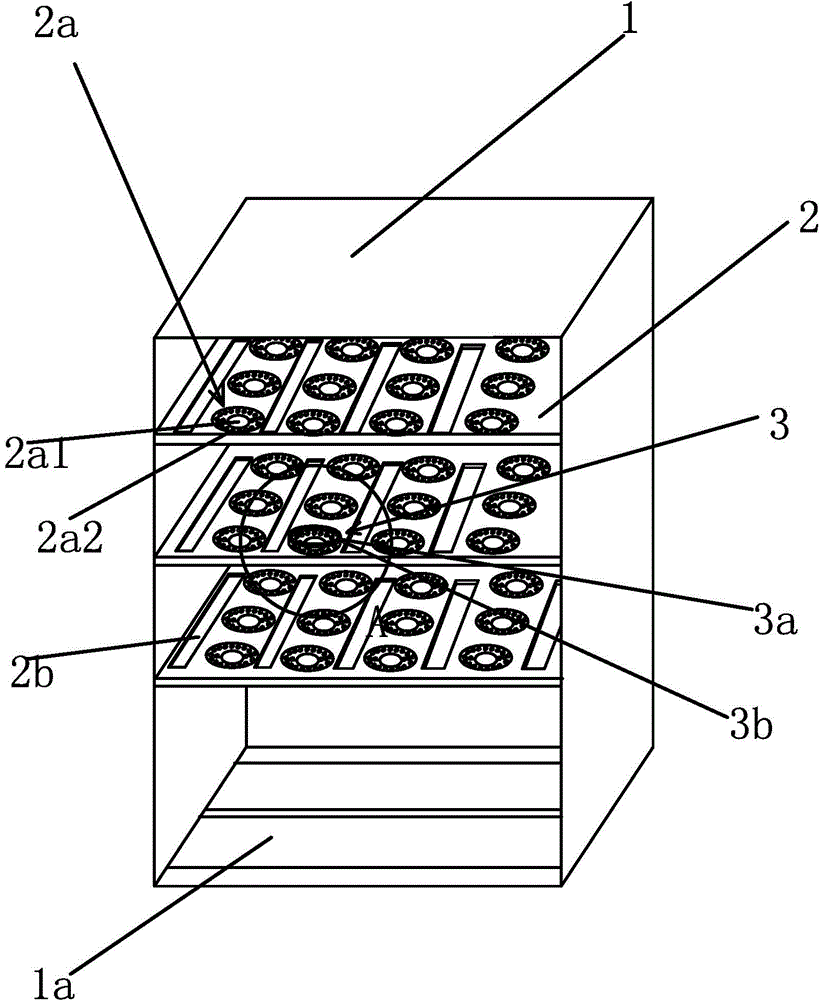

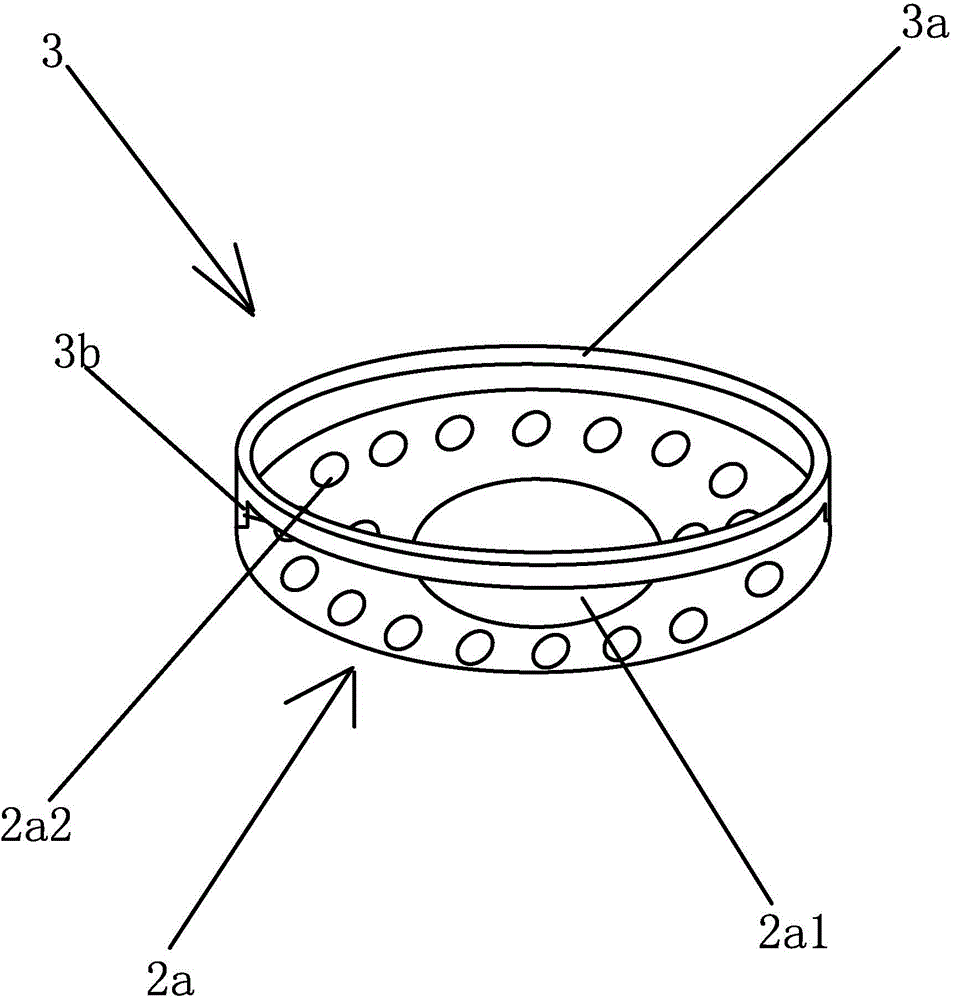

[0025] Such as figure 1 with figure 2 As shown, the batch cleaning device for optical lenses includes a box body 1 with an opening on one side and a square shape. There are multiple lens plates 2 arranged in parallel in the box body 1. The lens plates 2 are slidably connected to the inner wall of the box body 1. The plate 2 can slide out toward the opening direction of the cleaning device. The upper side of the lens plate 2 has a plurality of ellipsoidal lens grooves 2a for placing optical lenses. The lens grooves 2a are narrowed from top to bottom and the lens grooves 2a There is a bottom hole 2a1 that runs through both sides of the lens plate 2 at the center of the bottom of the lens plate 2. There are a plurality of water holes 2a2 that run through both sides of the lens plate 2 on the lens groove 2a. There is also a protruding fixing device 3 on the lens groove 2a. The device 3 includes a ring-shaped rubber ring 3a, the rubber ring 3a is located directly above the lens g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com