Perforated cleaner for optical lenses

A technology for cleaning equipment and optical lenses, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of poor cleaning effect and long cleaning time, so as to prevent lens from falling and increase stability Enhanced performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

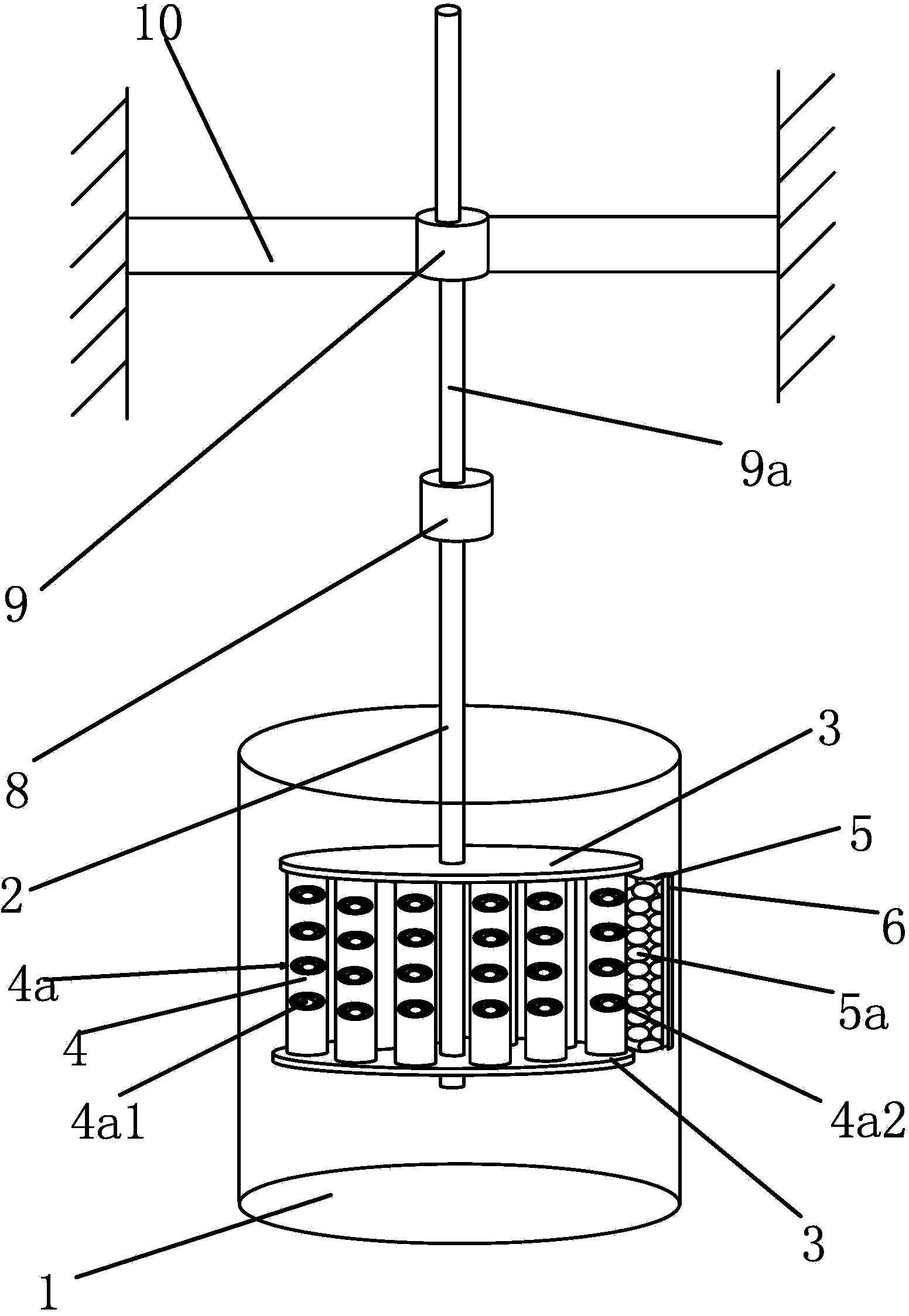

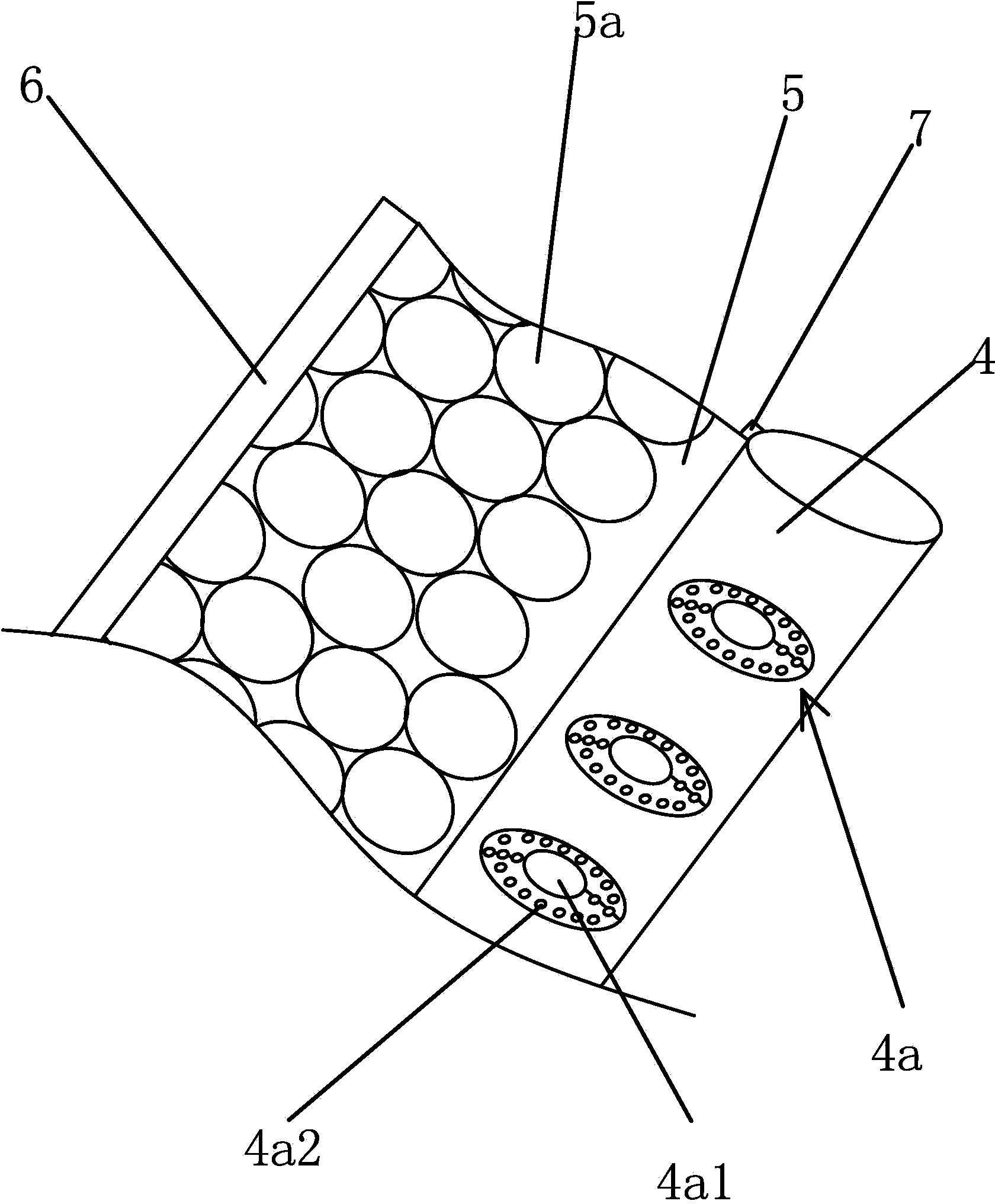

[0030] Such as figure 1 and figure 2 As shown, the cell cleaning equipment used for optical lenses includes a barrel-shaped cleaning barrel 1 with an opening at the upper end. The cleaning barrel 1 has a loading mechanism extending from the opening. The loading mechanism includes a vertically arranged loading shaft 2 And two loading boards 3 arranged in parallel and fixedly connected on the loading shaft 2, there are several cylindrical columns 4 between the two loading boards 3, and the outer wall of the column 4 has a plurality of optical The ellipsoidal lens groove 4a of the lens, the lens groove 4a is in the shape of a constriction and the bottom center of the lens groove 4a has a bottom hole 4a1 that runs through both sides of the column 4, and the two ends of the lens are located on the outer walls of both sides of the column 4. The groove 4a has a plurality of water passage holes 4a2 that run through both sides of the column 4, and the outer wall of one of the columns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com