Shape self-adaptive in-mold decorating method

A technology of self-adaptive mold and interior decoration, applied in coating and other directions, can solve the problems of increasing production cost, production cycle, complex shape, etc., and achieve the effect of reducing waste and saving production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

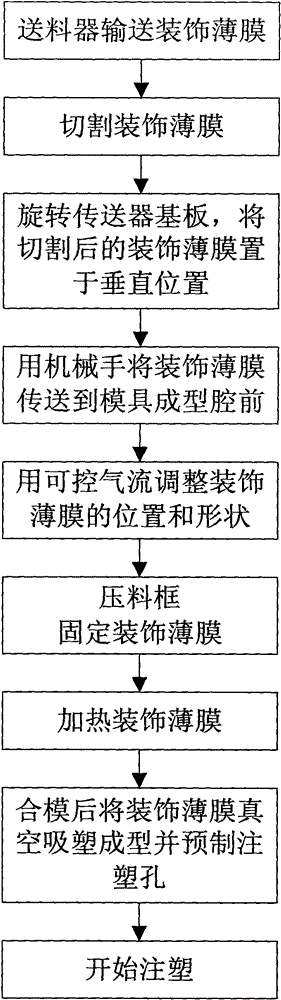

[0025] A specific embodiment of a shape-adaptive in-mold decoration method of the present invention will be explained below with reference to the accompanying drawings.

[0026] Firstly, the roll-shaped decorative film is placed on the conveyor substrate, and the feeder clamps the decorative film and conveys it to a set length. This kind of decorative film can generally be divided into three layers: (1) Substrate, generally polyethylene terephthalate, referred to as PET, or polycarbonate, referred to as PC, or polymethyl methacrylate, referred to as PMMA , the requirement for base material selection is that it has good molding and processing properties; (2) the ink layer, which is a printing material, requires wear resistance, high temperature resistance, and good performance in blending and screen printing operations; (3) protective film, or It is a special adhesive or polyethylene (PE). The requirement of the protective film is that it has good surface wear resistance and ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com