Cable for electric vehicle charging piles, preparation method and light-current flexible linear stranding device

A technology for electric vehicles and charging piles, which is applied in electric vehicle charging technology, electric vehicles, cable/conductor manufacturing, etc. Excellent efficiency, good temperature resistance and high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] [Example 1-cable and cable preparation]

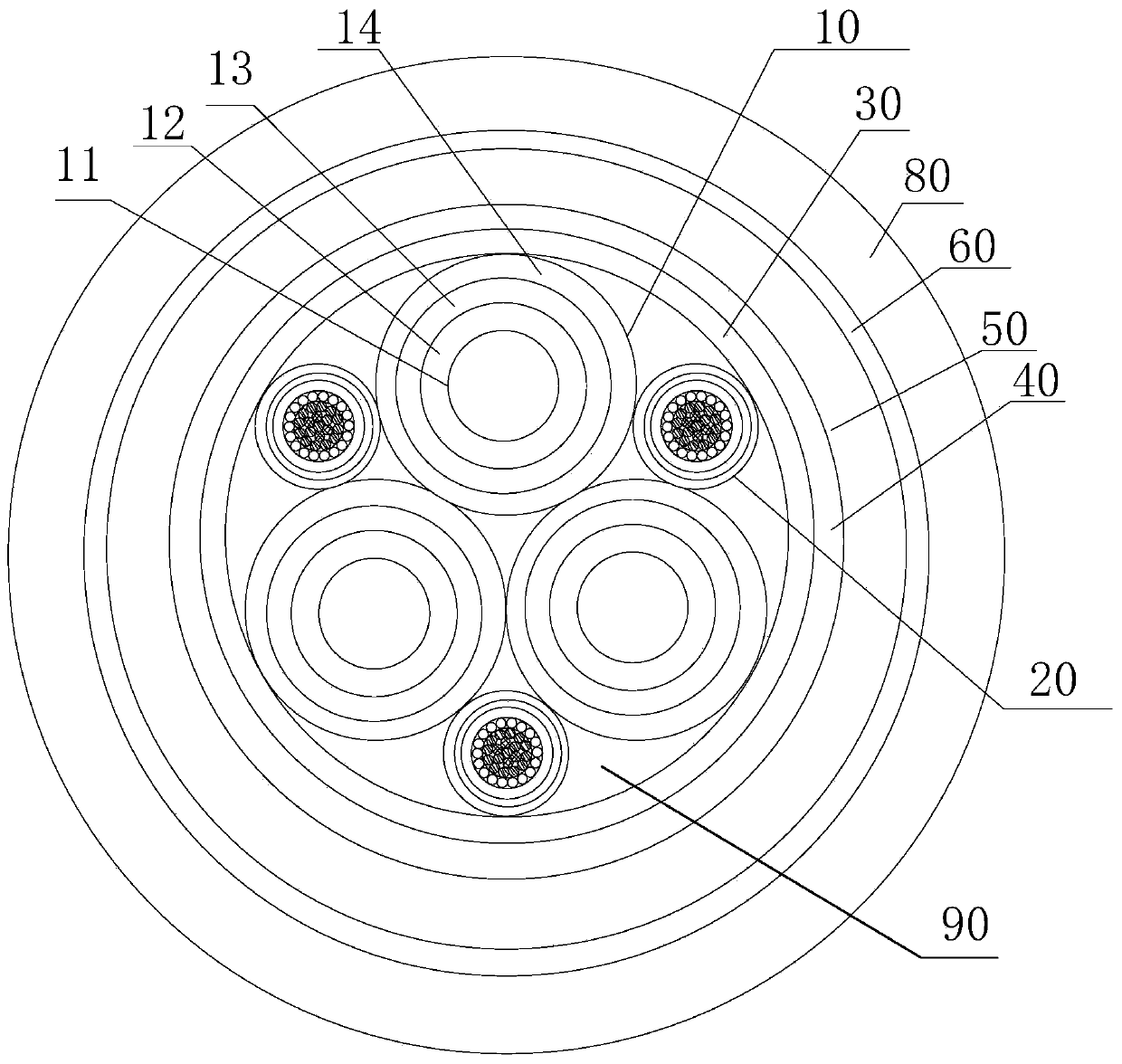

[0068] combine figure 1 , 2 As shown, the first aspect of the present invention discloses a cable for electric vehicle charging pile, including a battery core, a polyester tape layer 30 wrapped around the battery core, and a total shield wrapped around the polyester tape layer 30 Layer 40, the isolation layer 50 wrapped around the composite shielding layer 40, the braided layer 60 wrapped around the isolated layer 50, the outer sheath layer 80 arranged outside the braided layer 60 and filled in the rechargeable battery core 10 and the weak current Filling layer 90 between cores 20 and covered by polyester tape layer 30 .

[0069] The outer sheath layer 80 is formed on the braided layer by extruding polyvinyl chloride-rubber mixture, with a thickness of 1-3 mm. The filling layer 90 is filled with nylon filler.

[0070] combine figure 1 , 2 As shown, the battery cell has a charging battery cell 10 (a strong battery cell) and...

Embodiment 2

[0080] [Example 2-cable preparation process]

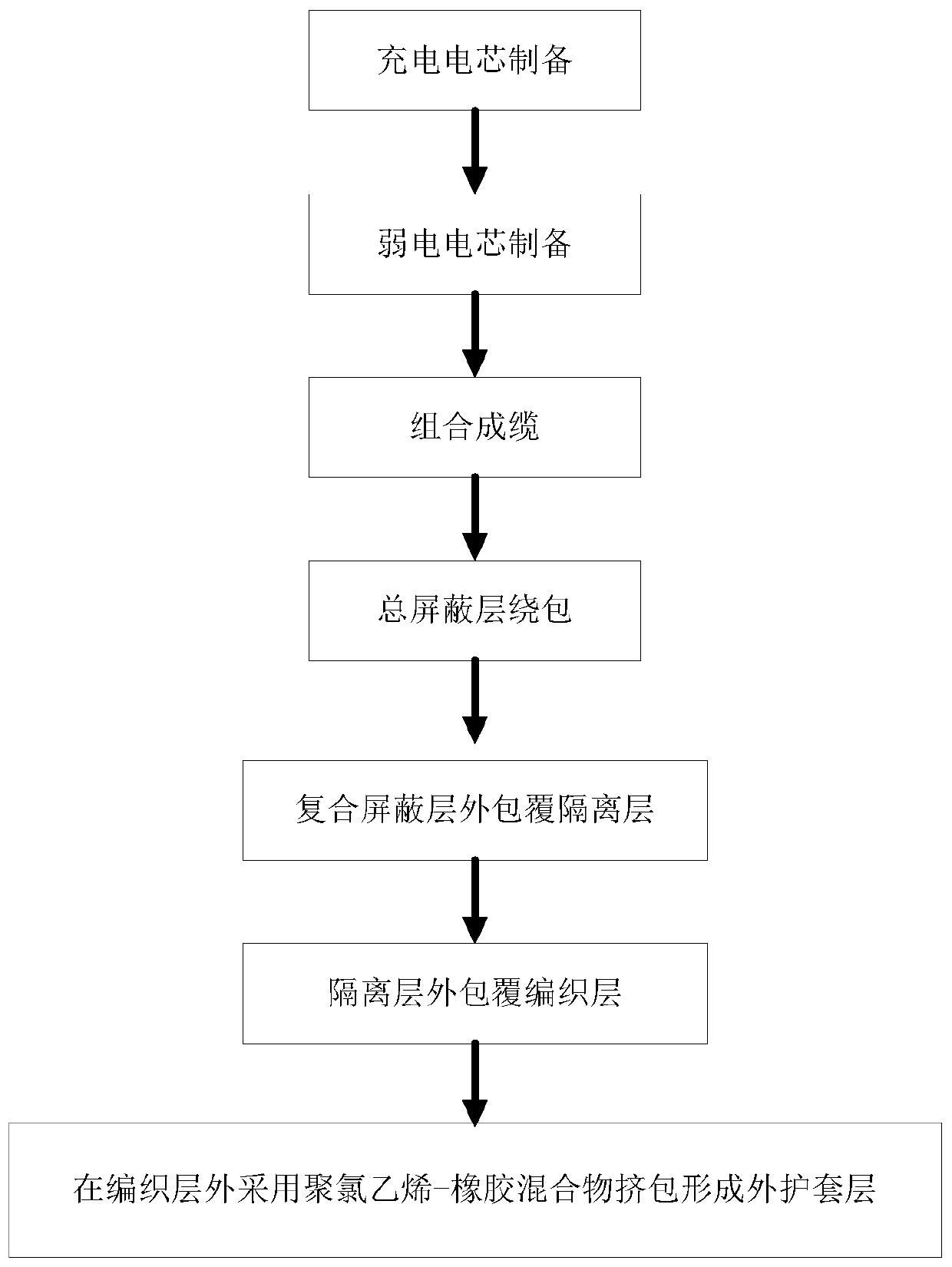

[0081] combine figure 1 and image 3 As shown, a method for preparing a cable for an electric vehicle charging pile is also proposed in the disclosed embodiments of the present invention, comprising the following steps:

[0082] Step 1. Preparation of charging cells

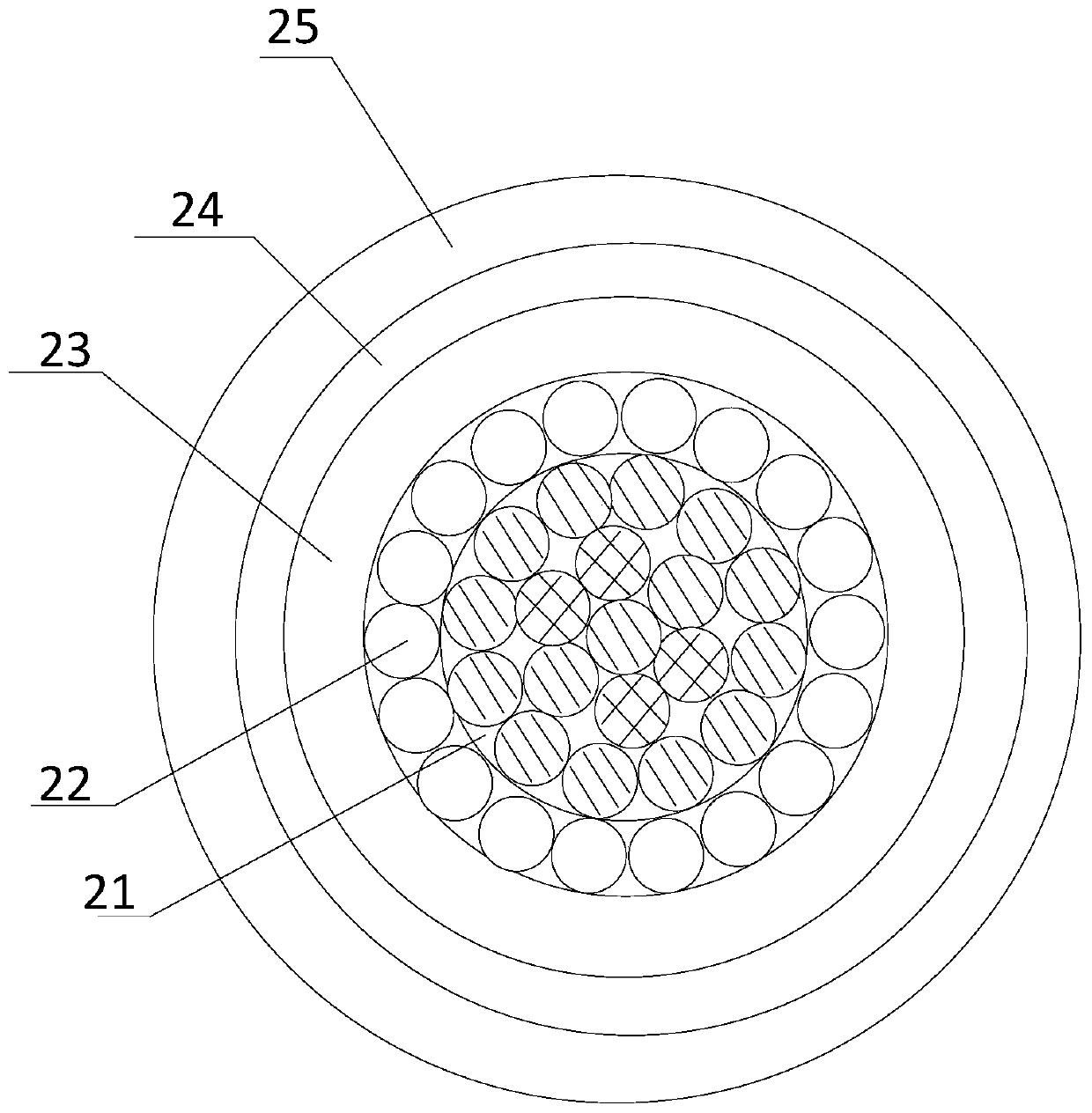

[0083]A plurality of silver-plated copper wires or tin-plated copper wires are twisted and then additionally braided with a layer of silver-plated copper wires or tin-plated copper wires as a conductive core. Fiber and metal wire composite braided composite shielding layer, in which the insulating layer is a silicone rubber insulating layer with a thickness of 1-2.4mm; the composite shielding layer contains 60%-70% of metal wire, and the braiding angle is controlled at 45±5°. The density is greater than 80%, and the thickness of the shielding layer is 0.3mm-0.8mm; the outer surface of the composite shielding layer is wrapped with polyester tape;

[0084] Step 2. ...

Embodiment 3

[0092] [Example 3 - Preparation of Flexible Wire Core]

[0093] combine Figure 3-6 As shown, in the cable preparation process of the present invention, in order to improve the wear resistance and tensile properties of the cable of the core charging cable, a special integrated twisting device is used for twisting when preparing the composite flexible core, combined with Figure 4-6 The structural representation of the twisting device is shown as an example.

[0094] combine Figure 3-6 , the twisting device includes a base plate 1 as a stranding base, an electric slider 2 is installed on the base plate 1, a moving frame 3 is installed on the electric sliding block 2, a rotating motor 4 is installed on the moving frame 3 through a motor base, and the rotating motor 4 A twisting mechanism 5 is provided on the output shaft.

[0095] A guide frame 6 is provided in the middle of the bottom plate 1 , and a flow guide mechanism 7 is provided at the rear end of the bottom plate 1 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com