Printed circuit board cleaning method, printed circuit board and circuit board clamp

A printed circuit board and circuit board technology, which is applied in the cleaning of printed circuit boards, printed circuit boards and circuit board fixtures, can solve the problems of water washing tank corrosion and corrosion, and achieve the effect of providing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

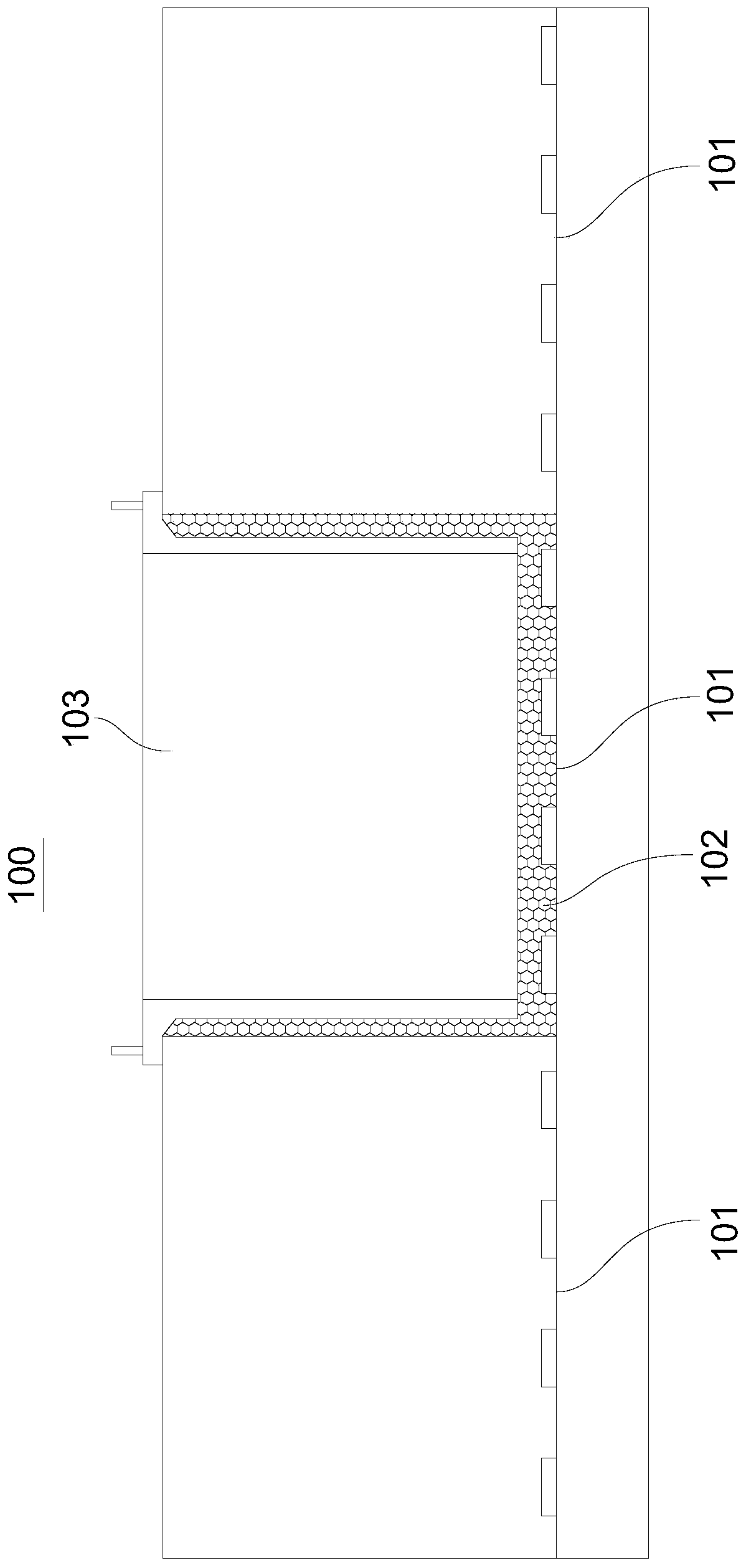

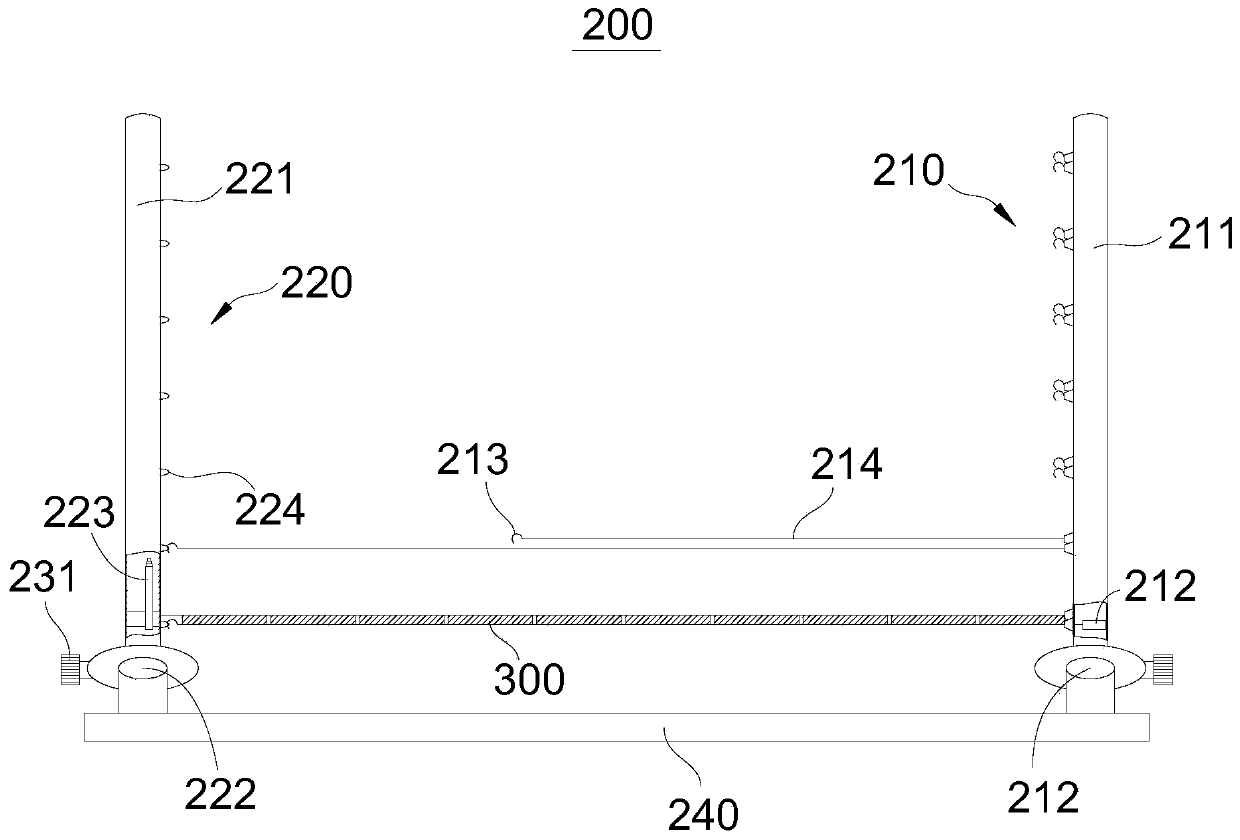

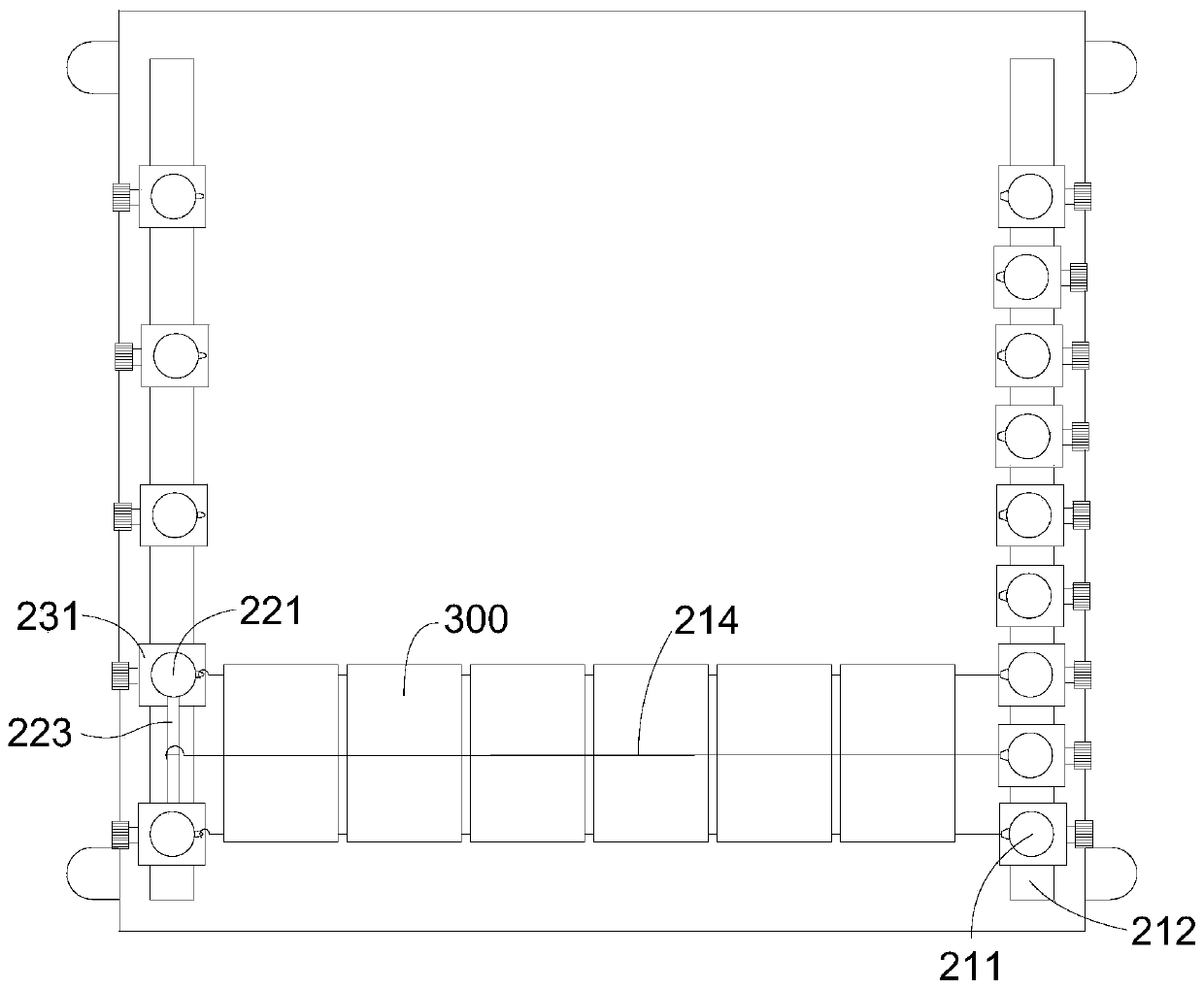

[0031] A cleaning method for a printed circuit board 300, comprising primary water washing, pre-neutralization treatment, secondary water washing, neutralization treatment and three water washings, referring to figure 1, in the three-stage water washing cylinder 100, the water washing cylinder 101 of the middle stage is used as pre-neutralization treatment. A pre-neutralization container 103 is arranged in the middle, and the isolation air cushion 102 can form a support for the pre-neutralization container 103 and is isolated from the water washing tank 101 in the middle stage. The inner wall of the pre-neutralization container 103 is provided with a corrosion-resistant coating. By isolating the air cushion 102, the pre-neutralization container 103 is isolated from the washing cylinder 101, avoiding the direct contact between the water-washing cylinder 101 and the pre-neutralization container 103, thereby causing abrasion, corrosion, etc.; And the container 103 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com