Ball valve

A technology of ball valves and ball cores, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc. It can solve problems such as difficulty in ensuring the reliability of bidirectional sealing, internal leakage of valves, wear of the ball core and the lower side of the sealing valve seat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0013] The structure of the ball valve of the present embodiment is as follows:

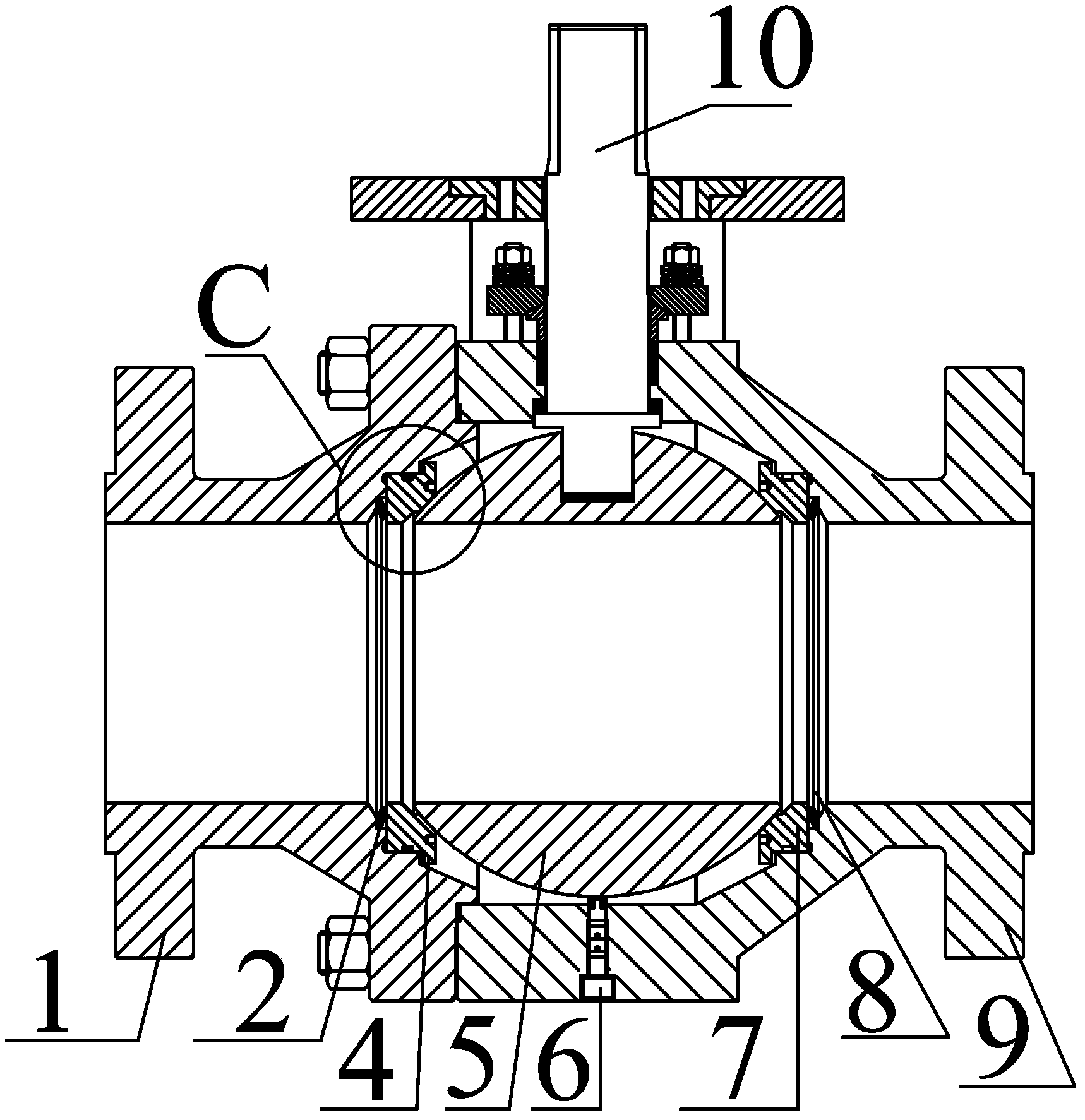

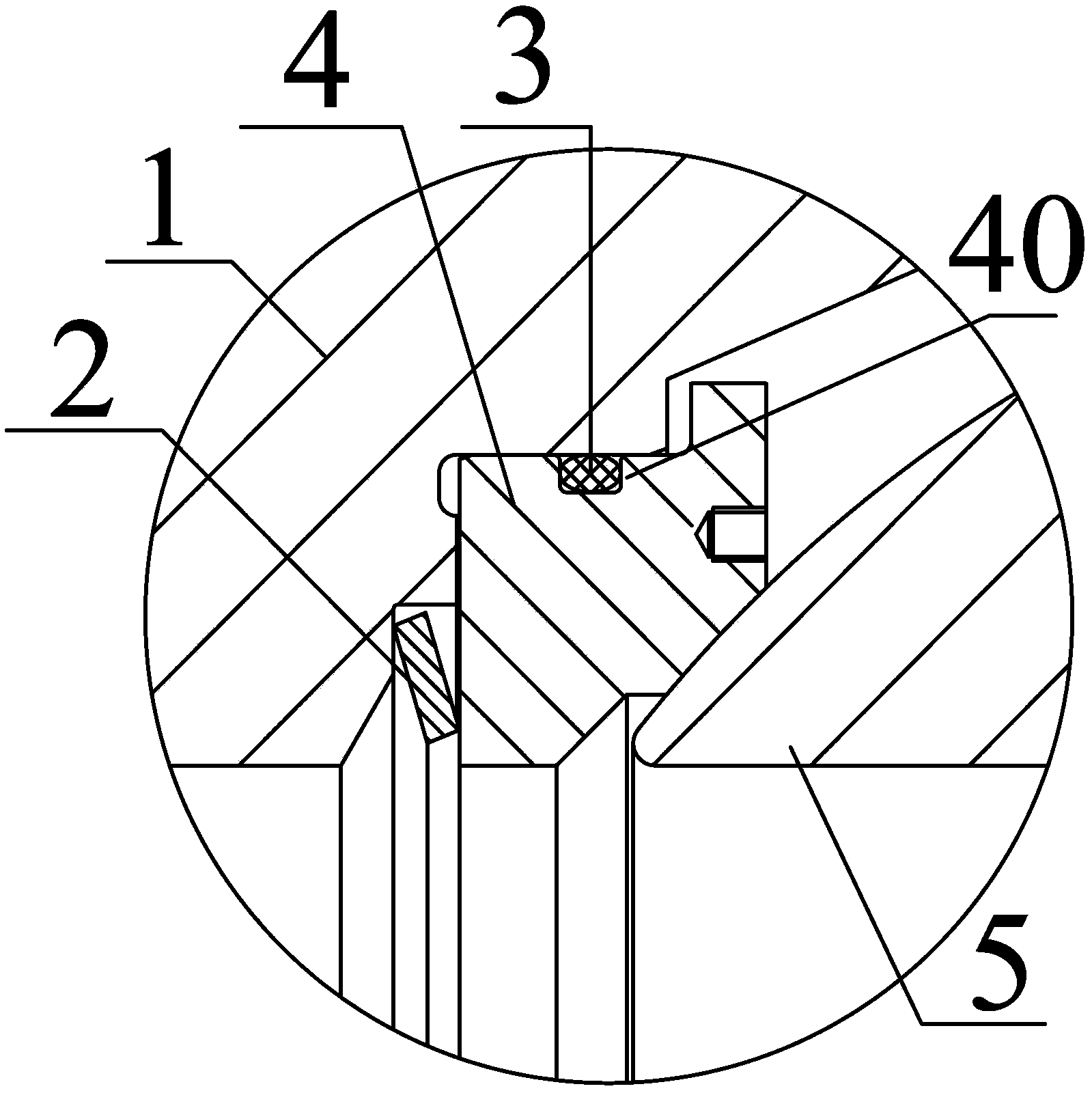

[0014] Please combine figure 1 It should be understood that the ball valve of this embodiment includes an auxiliary valve body 1, a first sealing valve seat 4, a ball core 5, a second sealing valve seat 7 and a main valve body 9, the auxiliary valve body 1 and the main valve body The valve bodies 9 are connected to each other, the first sealing valve seat 4, the ball core 5 and the second sealing valve seat 7 press against each other in sequence, and are arranged in the cavity formed by the auxiliary valve body 1 and the main valve body 9 A first elastic member 2 is arranged between the auxiliary valve body 1 and the first sealing valve seat 4 , and a second elastic member 8 is arranged between the second sealing valve seat 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com