Louver turning-plate awning

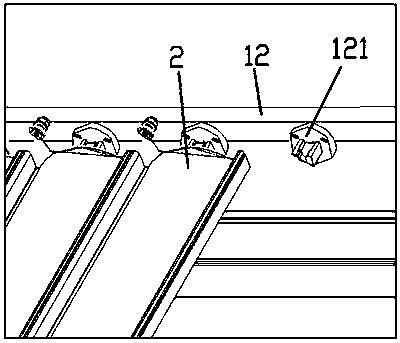

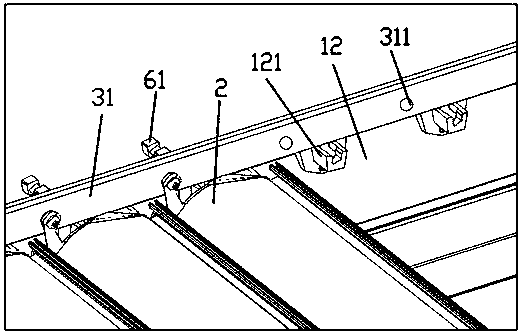

A technology of louver flaps and awnings, which is applied in the direction of tents/canopies, building types, buildings, etc., and can solve the problems of lack of drainage mechanisms, water seepage of louver flaps, side leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: the driving device is a manual handpiece 7;

[0069] Figure 5 It is a schematic diagram of the three-dimensional structure of the manual handpiece in the embodiment of the present invention.

[0070] Specifically, the manual machine head 7 is arranged on the outside of the right beam 14, and the manual machine head 7 corresponds to any one of the several louver flaps 2; The louver flaps corresponding to the head 7 are active louver flaps, and the rest of the louver flaps are driven louver flaps.

[0071] The manual handpiece 7 is driven based on a worm gear; specifically, the manual handpiece 7 includes a handpiece drive worm 71, a drive worm gear and a handpiece output pin 73 arranged inside the manual handpiece 7 , the driving worm 71 cooperates with the driving worm gear, and the head output pin 73 is arranged on the inner circumference of the driving worm wheel, that is, the head output pin 73 is rotated by turning the driving worm 71 .

[0072] In...

Embodiment 2

[0076] Embodiment 2: the driving device is a telescopic motor 8;

[0077] Figure 6 It is a schematic diagram of the three-dimensional structure of the telescopic motor in the embodiment of the present invention.

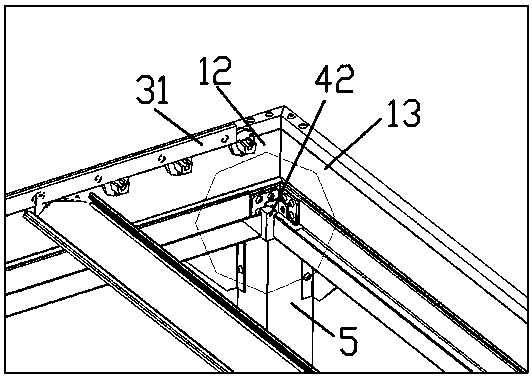

[0078]Specifically, the telescopic motor 8 is arranged in the first water tank at the lower end of the left beam 12, and the output end of the telescopic motor 8 corresponds to any one of the several louver flaps 2; wherein, The louver flaps corresponding to the telescopic motor 8 are active louver flaps, and the remaining louver flaps are driven louver flaps.

[0079] Specifically, the output end of the telescopic motor 8 is connected to the first louver end plate 21 of the active louver flap through a motor connector 81 .

[0080] In particular, the operation of the telescopic motor 8 can be remotely controlled by remote control, which facilitates the user's operation.

[0081] When it is necessary to control the opening and closing of the several louver flaps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com