Conical-axis Hooke's hinge

A technology of tapered shaft and hinge body, applied in the field of Hooke hinge, can solve the problem of low positioning accuracy of parallel positioning platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

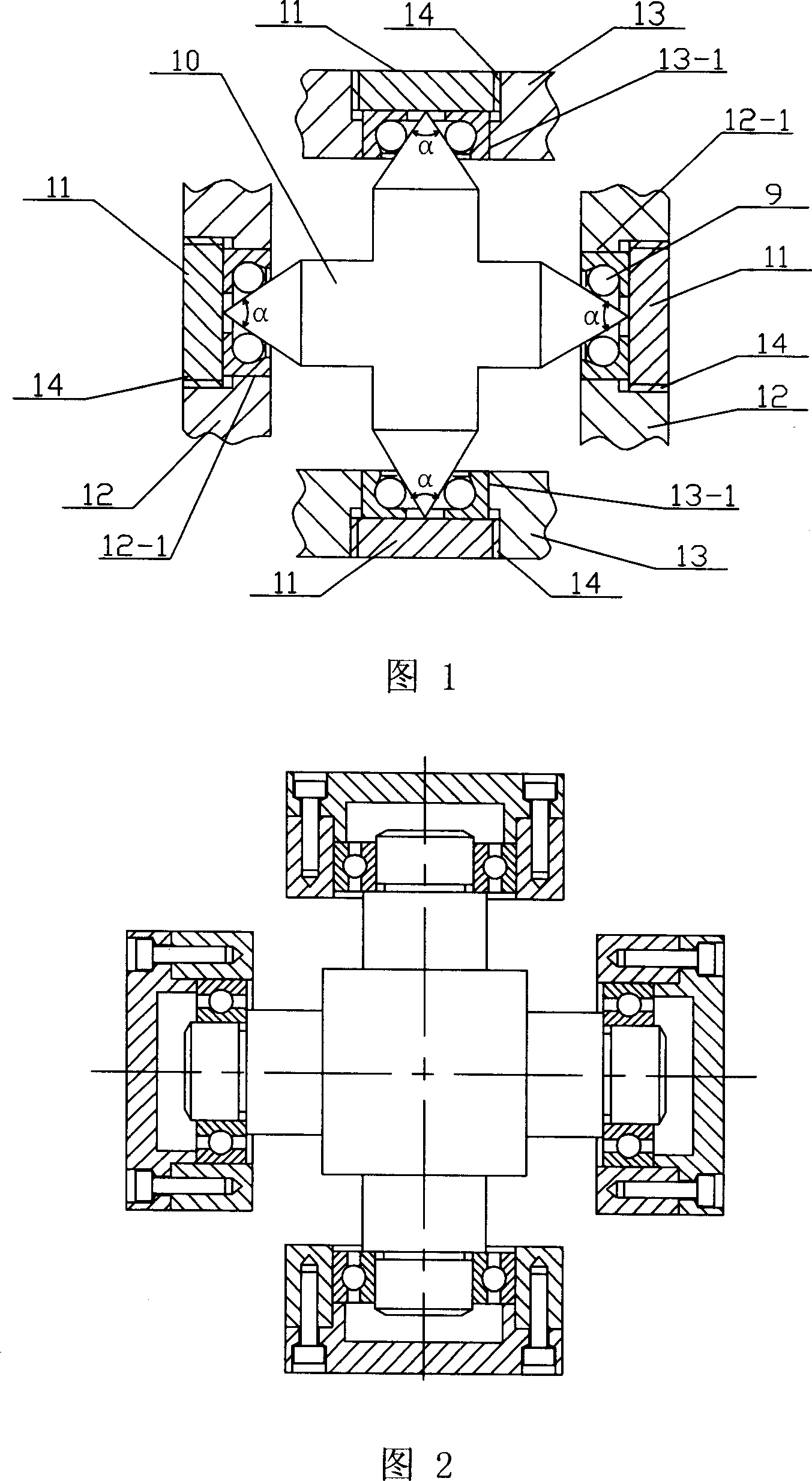

[0005] Specific Embodiment 1: This embodiment will be specifically described below with reference to FIG. 1 and FIG. 2 . The tapered shaft Hooke hinge consists of a cross point shaft 10, a ball bearing without an inner sleeve 9, a sealing end cover 11, a static hinge body 12 and a dynamic hinge body 13. The two ends of the cross point shaft 10 are conical. The cruciform body formed by being connected together has a No. 1 hole 12-1 on the static hinge body 12, and has No. 2 hole 13-1 on the dynamic hinge body 13, No. 1 hole 12-1 and No. 2 hole 13-1. There is an internal thread 14 on the surface of the inner hole at the outer end, and an external thread is opened on the outer surface of the sealing end cover. The ball bearing 9 is set in the inner cylindrical inner hole of the first hole 12-1 or the second hole 13-1. On the surface, the four conical ends of the cross point shaft 10 are inserted into the inner hole of the ball bearing 9, and the sealing end cover 11 is screwed in...

specific Embodiment approach 2

[0006] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 1 . The difference between the present embodiment and the first embodiment is that the tip angle α of the cross point shaft 10 is between 55° and 75°. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0007] Specific Embodiment Three: The present embodiment will be specifically described below with reference to FIG. 1 . The difference between the present embodiment and the second embodiment is that the tip angle α of the cross point shaft 10 is 60°. Other components and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com