Flip machine box, non-tool operation type locking device thereof and lock

A locking device, tool-less technology, applied in building locks, construction, building construction, etc., can solve the problems of inconvenient use of locking devices, unreliable locking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

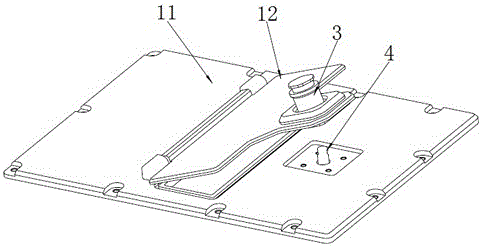

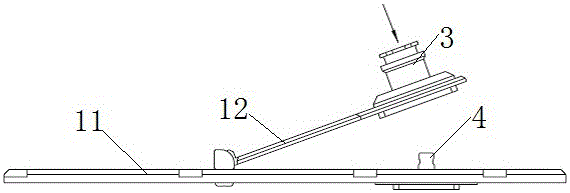

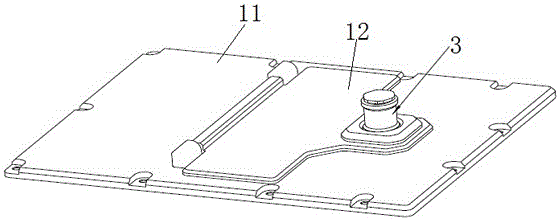

[0049] The specific embodiment of clamshell case of the present invention, as Figure 1 to Figure 7 As shown, the flip case includes a box body and a locking device arranged on the box body, the locking device includes a lock body 3 and a dead bolt 4, wherein the box body includes a box body panel 11 and a flip cover 12 arranged on the box body panel, The deadbolt 4 is arranged on the box body panel 11, and the lock body 3 is provided with a mounting seat, and the lock body 3 is fixed on the flip cover 12 through the mounting seat. In other embodiments, the lock body can also be arranged on the panel of the box body, while the lock tongue 4 is arranged on the flip cover.

[0050] The lock tongue 4 in this embodiment is provided with a lock groove 41 , the diameter of the lock tongue 4 is equivalent to the diameter of the small diameter section 315 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com