Multifunctional roadway maintenance and repair machine

A multifunctional roadway and repair machine technology, applied in tunnels, earth movers/shovels, mechanically driven excavators/dredgers, etc., can solve problems such as long construction time, small operating range, and many safety hazards. Achieve the effect of improving working efficiency, expanding the scope of use, and small matching clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

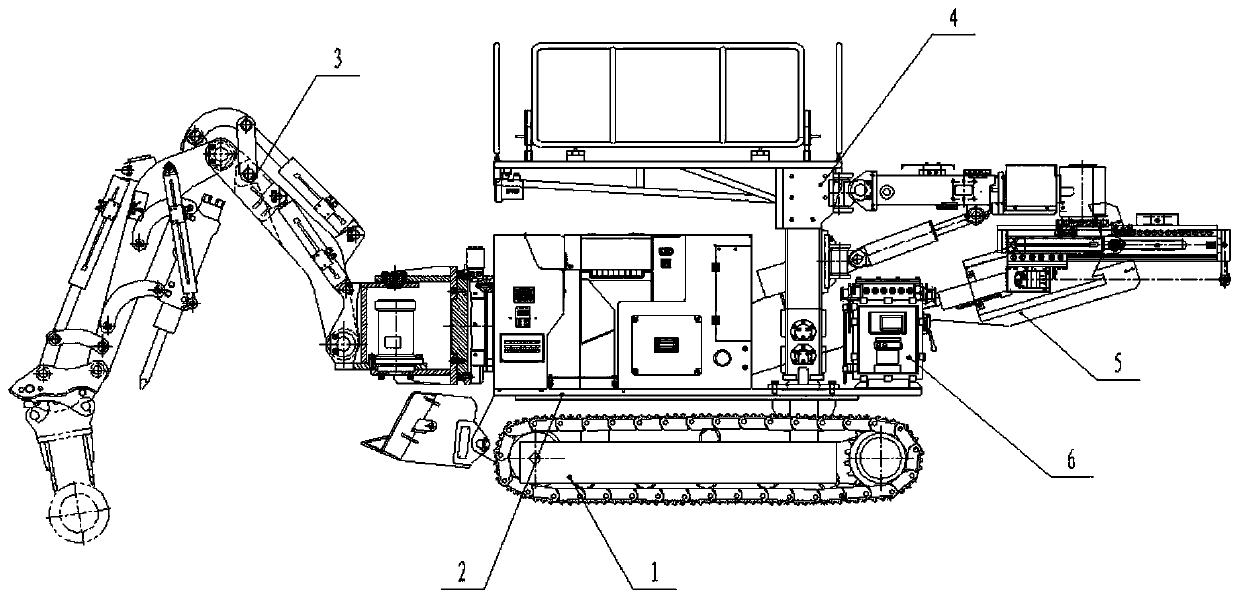

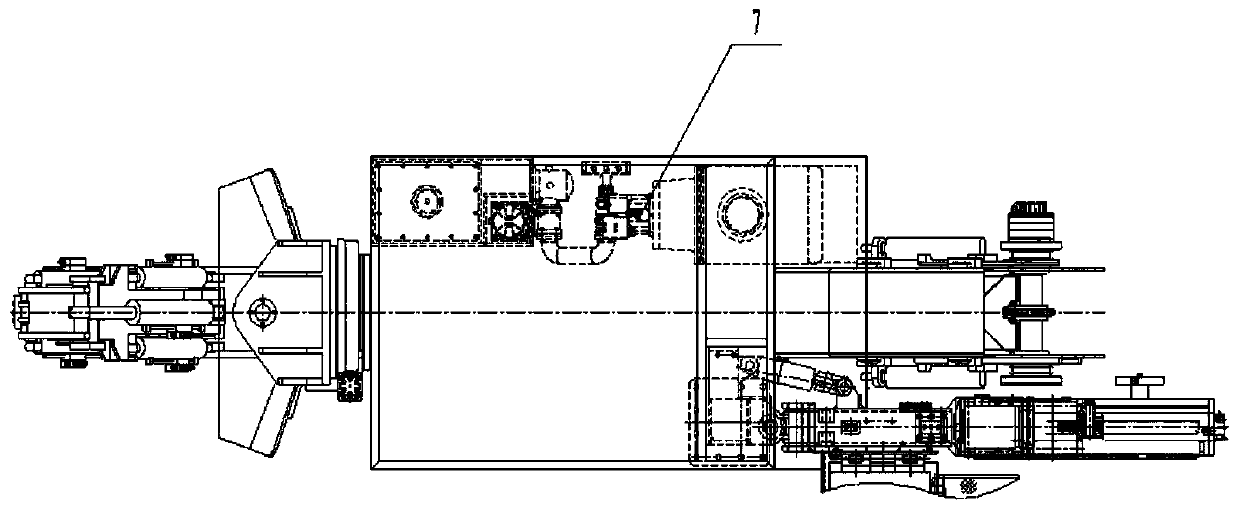

[0036] Such as Figure 1 to Figure 2 As shown, a multifunctional roadway maintenance and repair machine described in this embodiment includes a walking part 1, a body part 2, a cutting assembly 3, a drill arm part 4, a conveying part 5, an electrical system 6 and a hydraulic system 7; Described running part 1 is arranged on the below of body part 2, and cutting assembly 3 is arranged on the front end of body part 2, and drill arm part 4 is arranged on the left side of body part 2, and delivery part 5 is arranged in the middle of body part 2, The electrical system 6 is arranged on the left side of the body part 2 , and the hydraulic system 7 is arranged on the right side of the body part 2 .

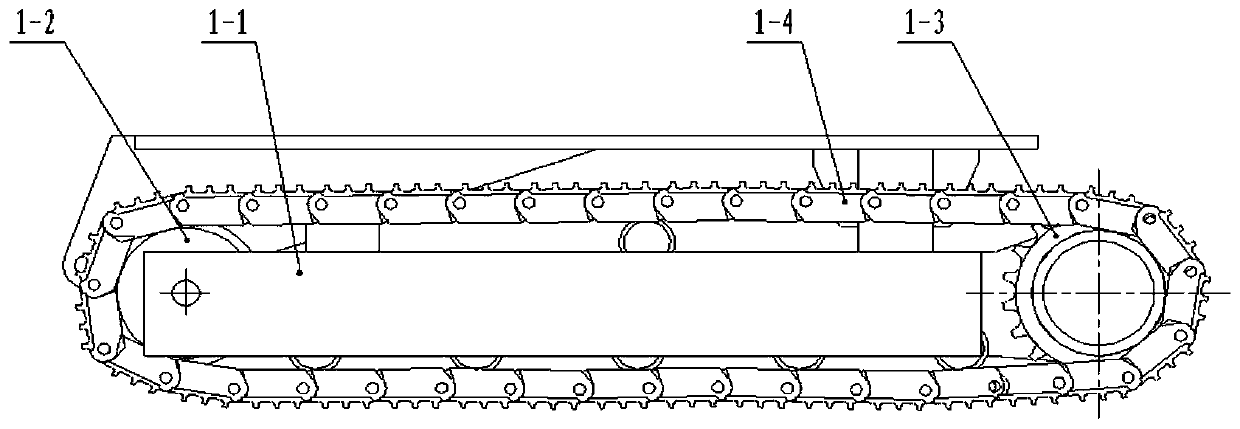

[0037] Such as Figure 3 to Figure 4 As shown, the walking part 1 is composed of a crawler frame 1-1, a reversing sprocket 1-2, a driving sprocket 1-3, a crawler belt 1-4, a tensioning device 1-5, a reducer 1-6 and a traveling hydraulic pressure Composed of a motor 1-7; the two redirect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com