Double nut precision ball screw pair

A ball screw pair and ball screw technology are applied in metal processing mechanical parts, metal processing, metal processing equipment and other directions, which can solve the problems of unsuitable nut rotation driving screw working mode, and achieve reliable axial preload, Axial rigidity and high reliability, the effect of high axial rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

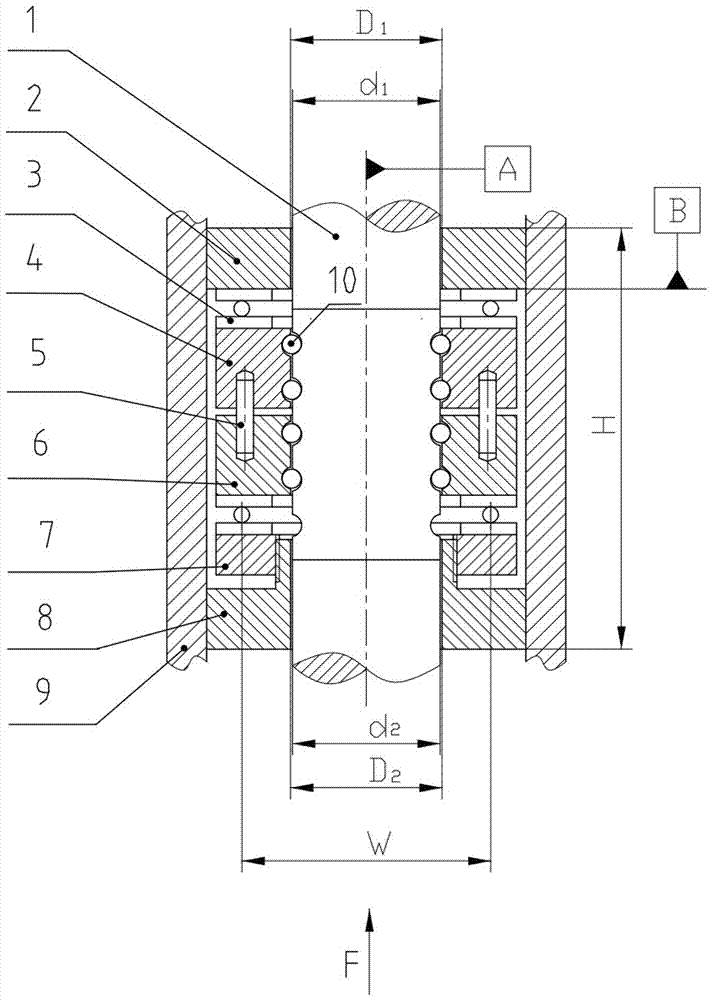

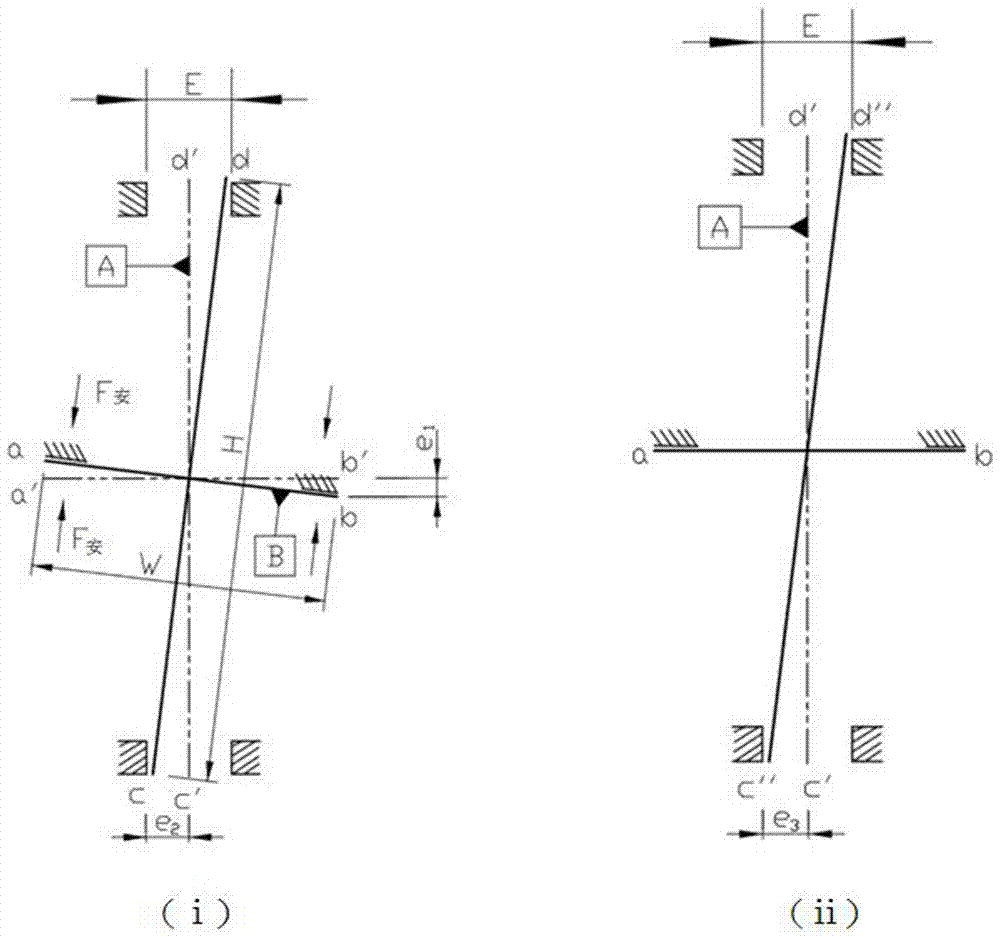

[0025] See figure 1 , the double-nut precision ball screw pair provided by the present invention includes a ball nut and a ball screw 1 that is driven by the ball nut and can only be fed axially. The ball screw 1 is in the cylindrical hole of the above sliding bearing 2 and Axial feed motion is performed on the common reference axis A formed by the cylindrical hole of the lower sliding bearing 8, the upper and lower sliding bearings 2, 8 are fixedly connected with the box body 9, and there are two gaps between the upper sliding bearing 2 and the ball screw 1. A symmetrical flat key (not shown in the figure) to prevent the ball screw 1 from rotating relative to the sliding bearings 2 and 8 when it moves up and down; the ball nut is composed of a main ball nut 4 and an auxiliary ball nut 6, and the ball nut The diameter of the ball 10 in the ball is slightly smaller than the diameter of the ball nut and the upper raceway of the ball screw 1. There is a certain gap between the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com