Boring machine

A boring machine and boring bar technology, applied in the field of boring machines, can solve the problems of small processing space, large volume, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

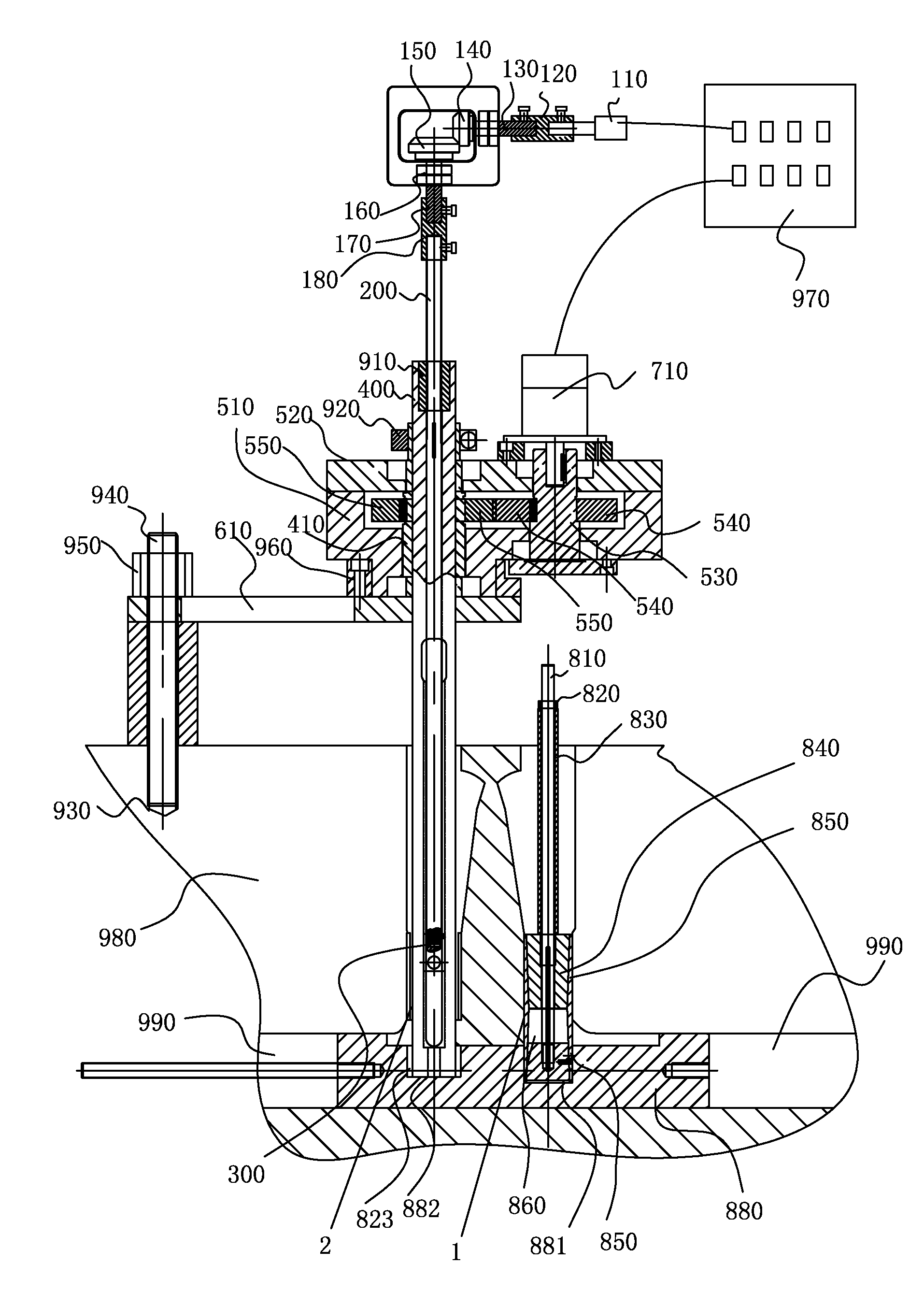

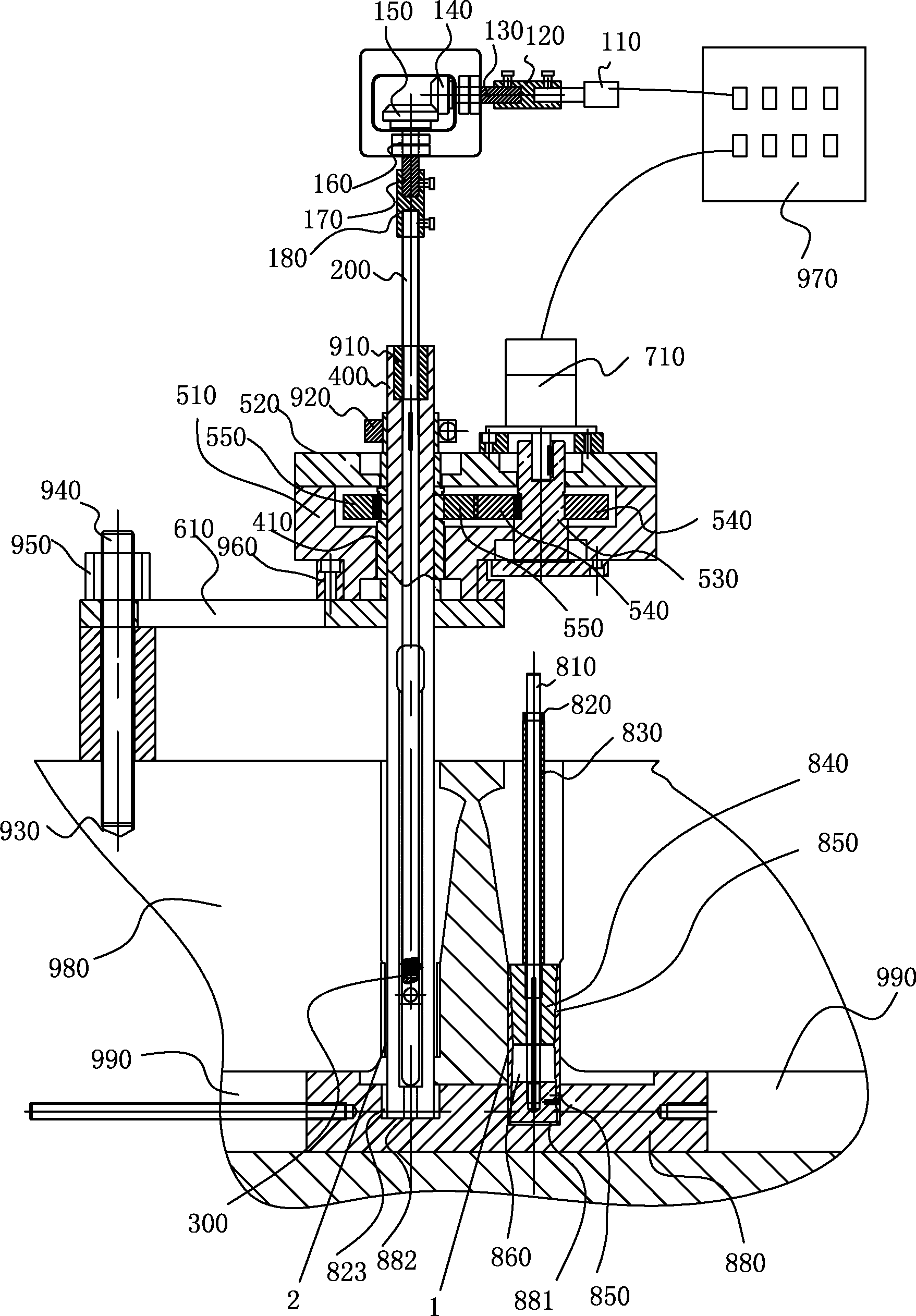

[0049] A boring machine such as figure 1 As shown, there are a boring knife feed drive device, a feed screw 200, a boring knife, a boring bar 400, a gear box part, a fixing bracket for a gear box part, a boring bar rotation driving device, and a boring bar positioning mechanism.

[0050] The boring bar positioning mechanism is provided with a first bolt 810 , a first nut 820 , a pressing tube 830 , an upper cone shaft 840 , a lower cone shaft 860 , a positioning taper sleeve 850 and a boring bar positioning shaft 880 .

[0051] The boring bar positioning shaft 880 is provided with a first hole 881 for assembling the positioning taper sleeve 850 and a second hole 882 for assembling the boring bar 400 .

[0052] The lower part of the first bolt 810 is threadedly connected with the lower cone shaft 860, the upper cone shaft 840 is sleeved on the outside of the first bolt 810 and arranged on the upper part of the upper cone shaft 840, and the positioning taper sleeve 850 is sleeve...

Embodiment 2

[0071] A V-shaped 20-cylinder engine with a power of 2000KW that is often used in production has two tappet holes of the camshaft, one of which has been worn out and becomes the tappet hole 2 for OEM processing, with a size of φ39.3mm . The other is intact and becomes the unworn tappet hole 1 with a size of φ39.02mm. If you need to continue to use, you must ream the worn hole and insert a bushing to continue normal use.

[0072] According to the characteristics of the tappet hole depth, small diameter, high dimensional accuracy and position accuracy, the invention provides a boring machine, which adopts processing technology to expand the hole and insert the bushing.

[0073] The cup lifter hole 2 to be processed is as follows: the size is φ39.3 mm in diameter, the hole depth is 70 mm, and the distance from the 980 cylinder head surface of the body is 230 mm. The hole is the hole for assembling the tappet, and the standard size should be φ39 mm, the actual wear is φ39.3mm....

Embodiment 3

[0121] A kind of boring machine, other structure is the same as embodiment 2, the difference is: the size of this boring machine is different from embodiment 2, the boring machine in this embodiment is applied to the hole size of the original tappet with a diameter of φ43 .9mm, hole depth is 20mm. Relevant dimensions can be adjusted as needed to meet the requirements, and details will not be repeated here.

[0122] Finally, it should be noted that the applicable occasions of the boring machine are not limited to the occasions of Embodiment 2 and Embodiment 3, and the boring machine is also suitable for other sizes of holes, as long as the relevant dimensions are adjusted according to specific needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com