High-frequency pulse discharge assisted surface rolling strengthening processing device and method

A high-frequency pulse discharge and processing device technology, which is applied in the field of metal surface strengthening, to improve wear resistance and fatigue resistance, facilitate loading and unloading and maintenance, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

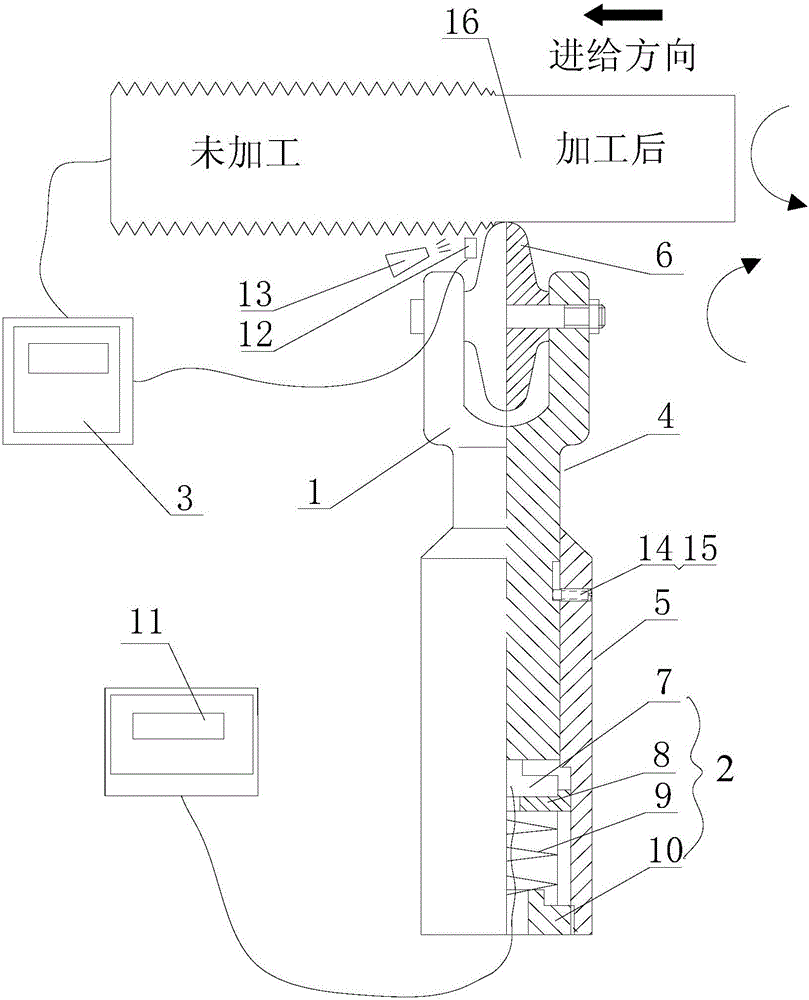

[0040] Taking Ti-6Al-4V round rod as the processing object, the surface rolling strengthening processing of Ti-6Al-4V round rod was carried out by using the surface rolling strengthening processing device assisted by high frequency pulse discharge.

[0041] First install the rolling mechanism 1 of the surface rolling strengthening processing device of the present invention on the tool rest of the machine tool, and align it with the workpiece 16 . Then connect the two poles of the high-frequency pulse discharge mechanism 3 to the workpiece 16 and the working electrode 12 respectively, open the cooling nozzle 13 on one side of the rolling wheel 6, and open the working medium.

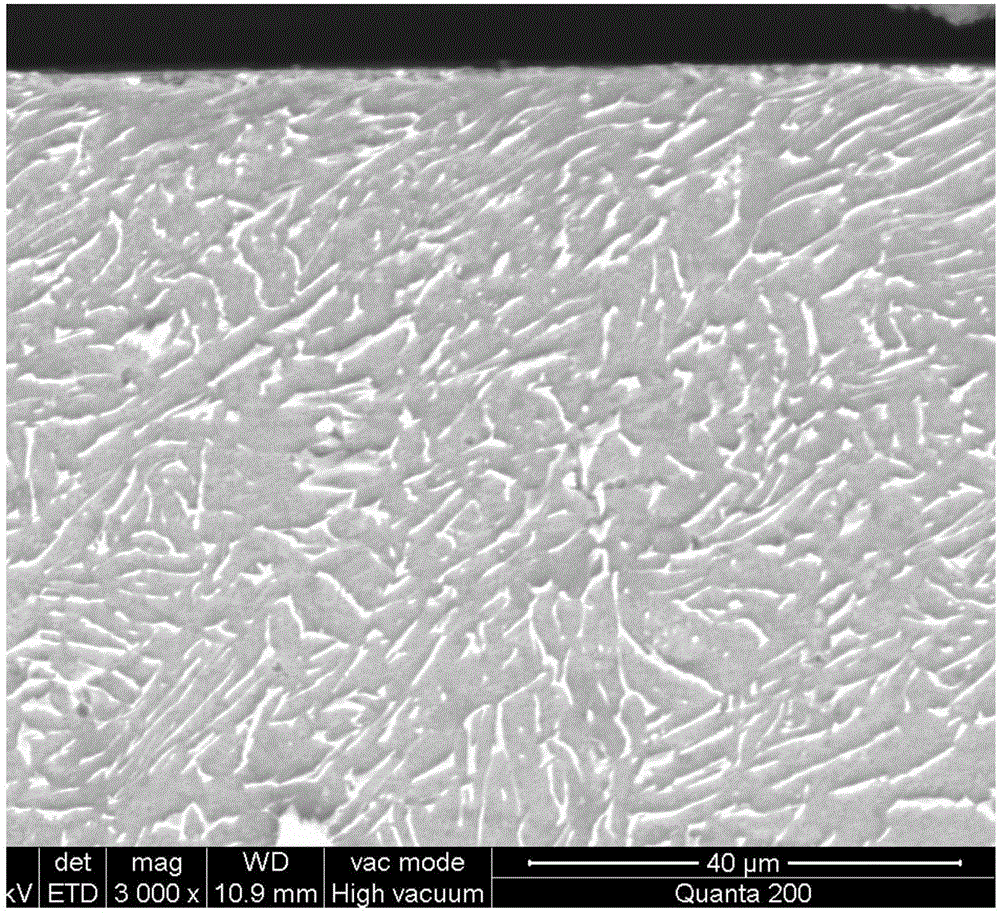

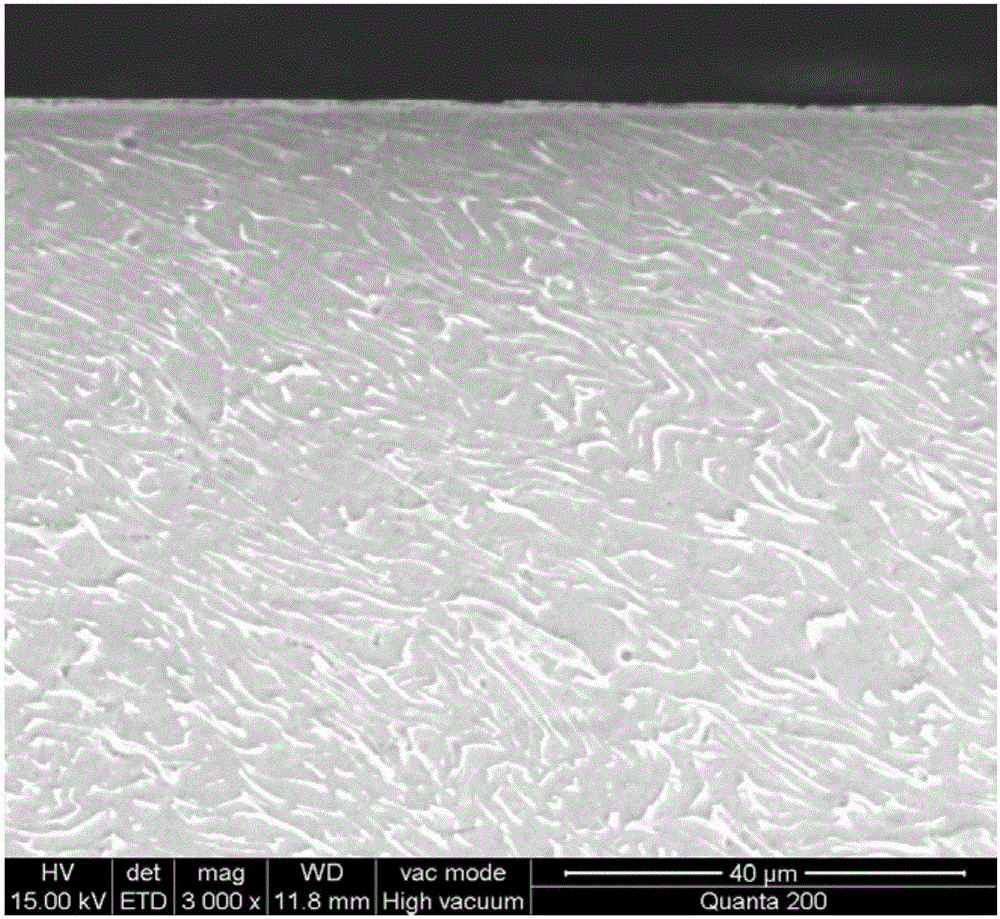

[0042] Then adjust the parameters of the process: the rotating speed of the workpiece is 240rpm, and the feed speed of the roller is 0.08mm / rev. Observe the pressure indicator 11 and apply a load of 750N to the rolled workpiece 16 . After the rolling process of the rolling wheel 6 to the Ti-6Al-4V round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com