Double-worktable-exchange device of laser cutting machine

A technology of double exchange worktable and laser cutting machine, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost, inconvenient operation and maintenance, complex structure of double exchange worktable, etc. Interfere with the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

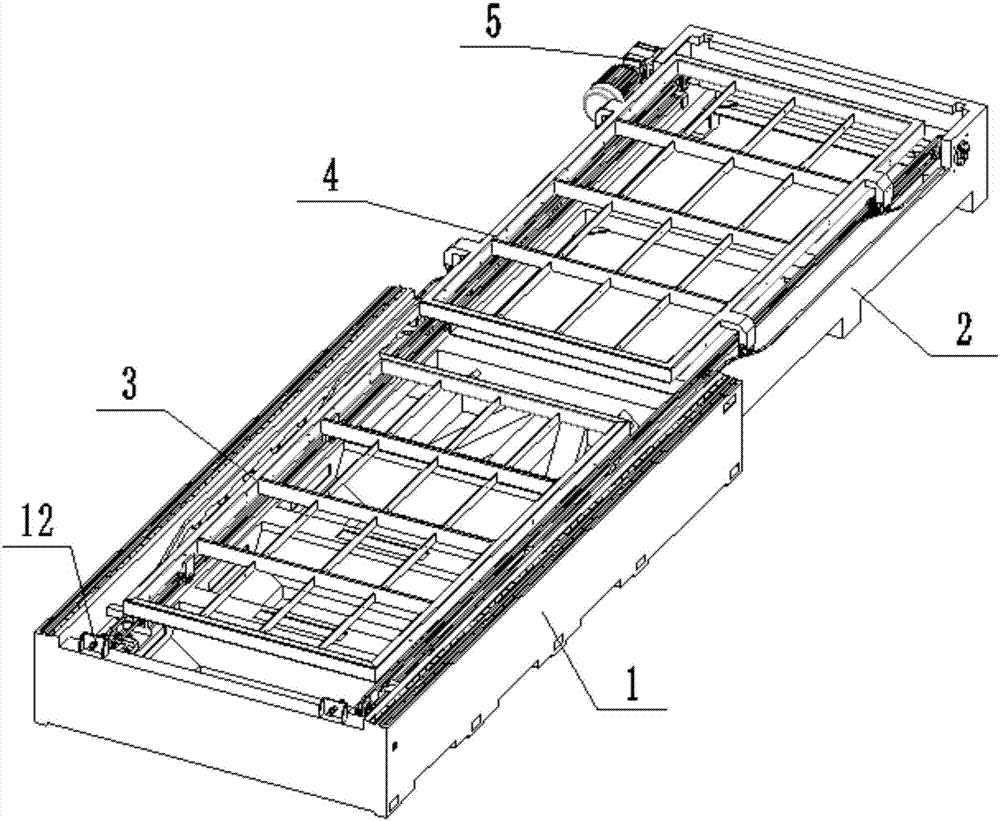

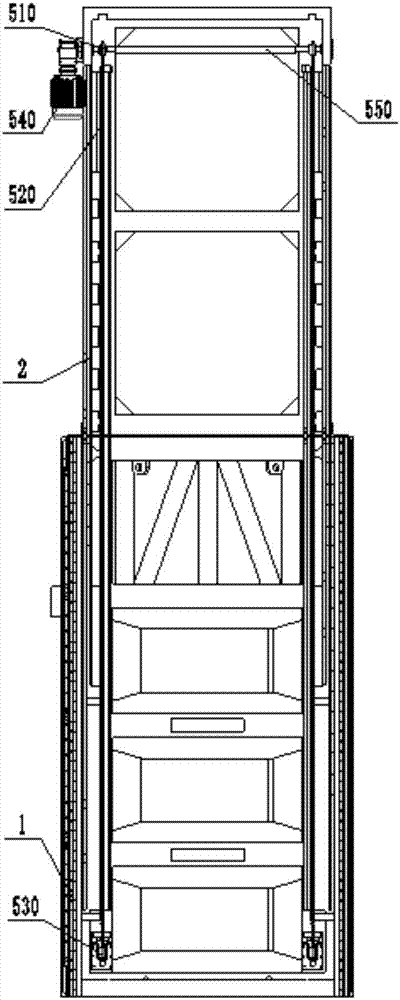

[0067] Such as figure 1 , image 3 , Figure 4 As shown, a laser cutting machine double-exchange workbench device in this embodiment includes a bed composed of a main bed 1 and an auxiliary bed 2, a first workbench 3 and a second workbench 4; wherein, the bed There is a workbench guide rail on it; the first workbench 3 and the second workbench 4 are set on the workbench guide rail, and are driven by a chain transmission mechanism 5 to realize position exchange between the main bed 1 and the auxiliary bed 2 . In this embodiment, the guide rails of the workbench include three guide rails arranged side by side on both sides of the bed body, which are respectively the outer guide rails of the lifting workbench, the inner guide rails of the lift workbench and the guide rails of the translation workbench from the outside to the inside; figure 2 It can be shown that the outer guide rail of the elevating workbench and the inner guide rail of the elevating workbench are both high i...

Embodiment 2

[0074] During the working process of the laser cutting machine, a large amount of smoke will be generated around the bed, and the structure of the bed needs to be designed. Generally, the smoke generated by cutting is sucked in by the suction port arranged around the bed, and discharged through the pipe. . In the actual cutting process, because the air suction port is far away from the high-temperature parts produced by the laser cutting head cutting metal, and the air suction port is relatively scattered, it cannot produce directional and concentrated air flow, so the ventilation effect is often not good; and the bed is used as a supporting part. It is necessary to install guide rails and racks to support the action of the beam, which requires high rigidity, otherwise it will cause post-processing deformation and affect the overall accuracy of the machine tool after assembly. Therefore, this embodiment further improves the structure of the main bed 1 on the basis of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com